Method for extracting and removing sulfur compound in crude oil

A compound and sulfide technology, which is applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of increasing desulfurization cost and cumbersome treatment process, and achieves low desulfurization treatment cost, easy preparation process and strong polarity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

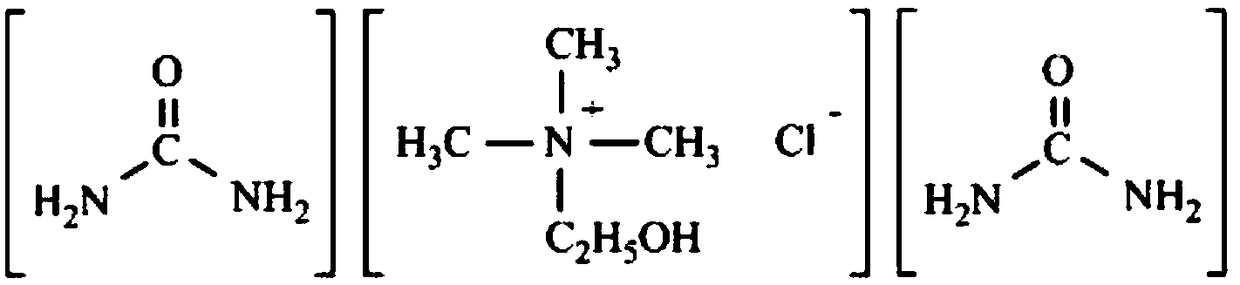

Image

Examples

Embodiment 1

[0037] Take 10.0g of crude oil A (sulfur content 1.16wt.%, moisture 3.55wt.%), add 1.5g of 30% hydrogen peroxide, and stir in a water bath at 50°C for 120min to obtain preoxidized crude oil A1.

[0038]Add 10.0 g of choline chloride / p-toluene acetic acid (molar ratio 1:1, freezing point 35°C) to the above preoxidized crude oil A1, extract in a water bath at 50°C for 30 minutes, take it out, and centrifuge at 4000 rpm for 3 minutes. 9.7g of the raffinate oil phase was collected, the sulfur content in it was reduced to 0.83wt.%, and the desulfurization rate was 28.4%; the water content in the oil was reduced to 2.53wt.%. Add 10.0 g of deionized water to the raffinate phase at 50° C., remove sulfur compounds by filtration, distill off water and dry to obtain a regenerated choline chloride / p-toluene acetic acid deep eutectic solvent.

Embodiment 2

[0040] Take 10.0g of crude oil A (sulfur content 1.16wt.%, moisture 3.55wt.%), add 0.5g of 30% hydrogen peroxide and 0.95g of sodium percarbonate, and stir in a water bath at 55°C for 90min to obtain preoxidized crude oil A2.

[0041] Add 10.0 g of choline chloride / p-toluene acetic acid (molar ratio 1:1, freezing point 35°C) to the above preoxidized crude oil A2, extract in a water bath at 55°C for 20 minutes, take it out, and centrifuge at 4000 rpm for 3 minutes. 9.6g of the raffinate oil phase was collected, the sulfur content in it was reduced to 0.70wt.%, and the desulfurization rate was 39.6%; the water content in the oil was reduced to 1.53wt.%. Add 10.0 g of deionized water to the raffinate phase at 55° C., filter to remove sulfur compounds, distill off water and dry to obtain a regenerated choline chloride / p-toluene acetic acid deep eutectic solvent.

Embodiment 3

[0043] Take 10.0g of crude oil B (sulfur content 0.64wt.%, moisture 6.25wt.%), add 1.1g of sodium percarbonate, and stir in a 60°C water bath for 70min to obtain preoxidized crude oil B1.

[0044] Add 10.0g choline chloride / L-malic acid (molar ratio 1:1, freezing point 18°C) to the above-mentioned preoxidized crude oil B1, extract in a water bath at 60°C for 30 minutes, take it out, and centrifuge at 4000rpm for 3 minutes. 9.8g of the raffinate oil phase was collected, the sulfur content in it was reduced to 0.42wt.%, and the desulfurization rate was 34.4%; the water content in the oil was reduced to 1.21wt.%. Add 10.0 g of deionized water to the raffinate phase at 60° C., filter to remove sulfur compounds, distill off water and dry to obtain a regenerated choline chloride / L-malic acid deep eutectic solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com