A self-supporting graphene film/polyaniline@polyaniline hierarchical structure composite electrode, preparation method and application

A graphene film and composite electrode technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve problems such as poor stability and low specific capacity, and achieve the advantages of avoiding agglomeration, reducing internal resistance and retaining flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Immerse the cut graphene film in 40ml of 0.1M camphorsulfonic acid solution, then add 0.6mmol of aniline monomer, stir well, then add 20mL of 0.1M sodium persulfate solution to initiate the polymerization of aniline monomer, and react for 6 hours at room temperature Take out the sample, rinse it with a large amount of deionized water and ethanol, and then dry it overnight in a vacuum oven to obtain sample 1, which is marked as graphene / polyaniline;

Embodiment 2

[0030] The sulfuric acid of configuration 0.1M and the aniline solution of 0.1M, wherein the ratio of water and ethanol is 1:1, the sample 1 (graphene film / polyaniline) gained in the above-mentioned embodiment 1 is immersed in this electrolytic solution, at 0.8V Constant voltage electrodeposition under voltage for 10 min, followed by washing with deionized water and drying to obtain sample 2, marked as graphene / polyaniline@polyaniline.

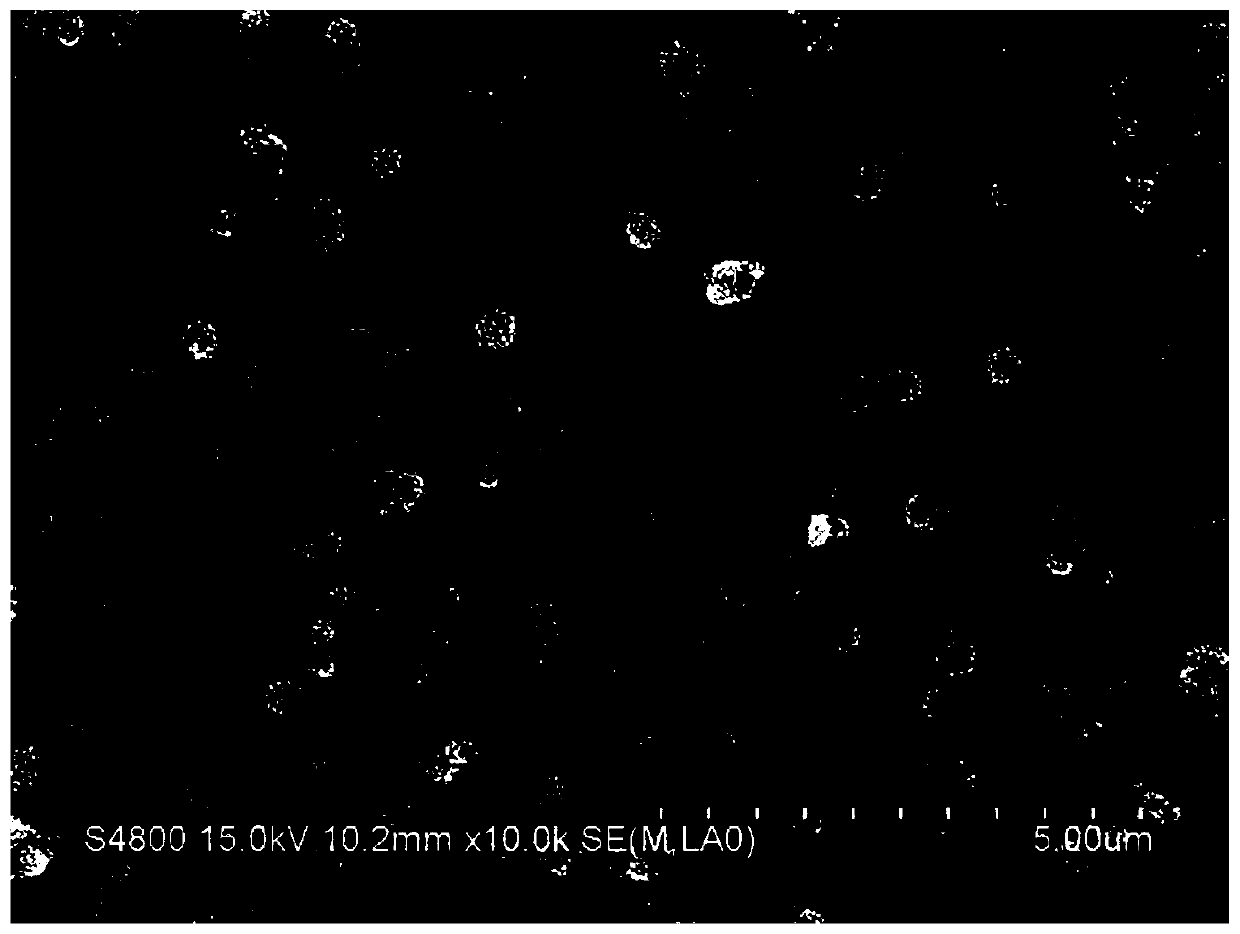

[0031] The morphology of the above graphene / polyaniline and graphene / polyaniline@polyaniline composite electrode materials was characterized by a field emission scanning electron microscope (JSM-4800);

[0032] The composite electrode materials in Example 1 and Example 2 are directly used as the working electrode after drying, and the solution of sodium sulfate of 1M is configured as the electrolyte at the same time, the platinum sheet is used as the counter electrode, and the Ag / AgCl electrode is used as the reference electrode to form three e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com