Preparation method of cellophane

A technology of cellophane and mass ratio, which is applied in the direction of paper, papermaking, paper machines, etc., can solve the problems of poor moisture-proof, waterproof and mildew-proof performance, difficult removal of cellophane ink, easy tearing of cellophane, etc., and achieves strong decontamination and increased neutralization Ability, stable effect for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

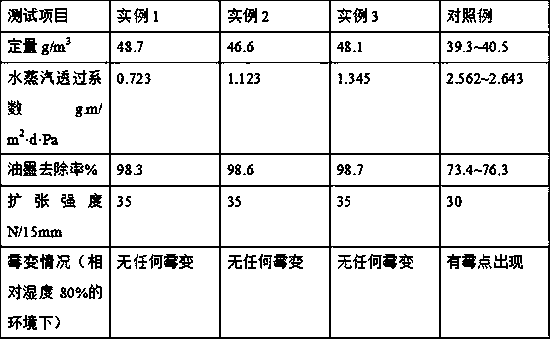

Examples

preparation example Construction

[0019] A preparation method of cellophane, comprising the steps of:

[0020] (1) Take sodium oleate and mix it with deionized water at a mass ratio of 1:9, filter, take the filtrate, adjust the pH to 7~7.2, add acrylic acid with a mass of 30~40% of the filtrate, heat up to 60~70°C and stir and mix for 1 ~2h, then add ammonium persulfate, keep for 2~3h, adjust the pH to 8~9, get the mixed solution, take the waste paper and cut it into small pieces, add the temperature of 60~65℃ according to the mass ratio of 1:8:5 Put water and mixed solution in a pulper to homogenize for 30-40 minutes, take the homogenized solution and add dichloromethane in a mass ratio of 2:9 to mix, keep at 60-70°C for 2-3 hours, and rotate to evaporate to obtain the rotary evaporated product;

[0021] (2) Take dimethyl diallyl ammonium chloride and acrylamide, add deionized water in a mass ratio of 1:2:10, stir and mix for 20-30 minutes to obtain mixture A, take octadecyl acrylate, Tween-60 Add diesel oil...

Embodiment 1

[0027] Polypropylene carbonate coarse powder: purchased from Inner Mongolia Mengxi High-tech Group Company.

[0028] A preparation method of cellophane, comprising the steps of:

[0029] (1) Take sodium oleate and mix it with deionized water at a mass ratio of 1:9, filter, take the filtrate, adjust the pH to 7, add acrylic acid with a mass of 30% of the filtrate, heat up to 60°C and stir for 1 hour, then add ammonium persulfate , keep for 2 hours, adjust the pH to 8 to obtain the mixed solution, take the waste paper and cut it into small pieces, add water and the mixed solution at a temperature of 60°C according to the mass ratio of 1:8:5, and put it in a pulper for homogenization for 30 minutes. Take the homogenate and add dichloromethane at a mass ratio of 2:9 to mix, keep at 60°C for 2 hours, and rotate to evaporate to obtain a rotary evaporate;

[0030] (2) Take dimethyl diallyl ammonium chloride and acrylamide in a mass ratio of 1:2:10, add deionized water, stir and mix ...

Embodiment 2

[0036] Polypropylene carbonate coarse powder: purchased from Inner Mongolia Mengxi High-tech Group Company.

[0037] A preparation method of cellophane, comprising the steps of:

[0038] (1) Take sodium oleate and mix it with deionized water at a mass ratio of 1:9, filter, take the filtrate, adjust the pH to 7.2, add acrylic acid with a mass of 40% of the filtrate, heat up to 70°C and stir for 2 hours, then add ammonium persulfate , keep for 3 hours, adjust the pH to 9 to obtain the mixed solution, take the waste paper and cut it into small paper pieces, add water and the mixed solution at a temperature of 65°C according to the mass ratio of 1:8:5, put it in a pulper for homogenization for 40 minutes, Take the homogenate and add dichloromethane at a mass ratio of 2:9 to mix, keep at 70°C for 3 hours, and rotate to evaporate to obtain a rotary evaporate;

[0039] (2) Take dimethyl diallyl ammonium chloride and acrylamide at a mass ratio of 1:2:10, add deionized water, stir and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com