A method for preparing highly active gold/zinc oxide composite nanoclusters in one pot at room temperature

A zinc oxide, nano-cluster technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, special compound water treatment, etc. It has the advantages of excellent photocatalytic degradation characteristics, low cost, and simple and easy-to-operate process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of Au / ZnO Composite Nanoclusters with 0.5 wt% Au Loading

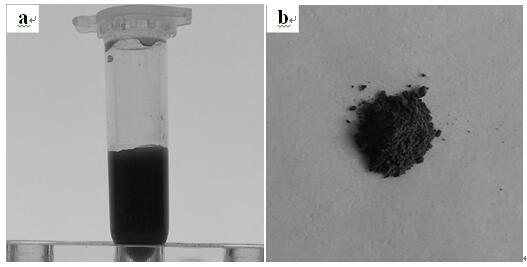

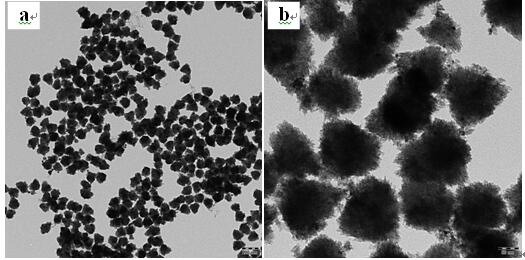

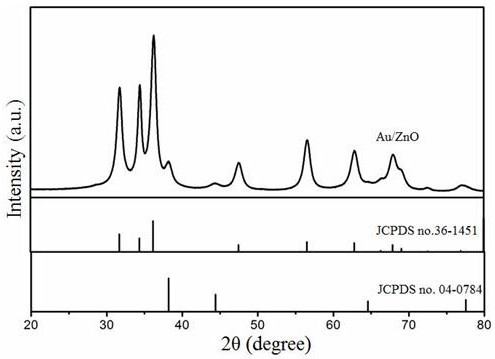

[0025]Under stirring conditions at room temperature, first add 14 milliliters of deionized water to 80 milliliters of ethylene glycol solution, then add 1 milliliter of 5 mol / liter zinc chloride aqueous solution and 5 milliliters of 5 mol / liter sodium hydroxide aqueous solution successively, at room temperature After stirring and reacting for 30 minutes, slowly add 83 microliters of sodium chloroaurate solution with a concentration of 0.125 mol / liter dropwise, the color of the solution gradually changes from milky white to purple black, and the reaction is continued for 10-30 minutes to obtain gold / zinc oxide composite nano Cluster colloid solution, after the reaction is finished, centrifuge the gold / zinc oxide composite nano-cluster colloid solution at a speed of 8000 rpm, remove the colorless supernatant in the centrifuge tube, and obtain a purple-black precipitate product, which is ultrasonically c...

Embodiment 2

[0027] Preparation of Au / ZnO Composite Nanoclusters with 1 wt% Au Loading

[0028] Under stirring conditions at room temperature, first add 14 milliliters of deionized water to 80 milliliters of ethylene glycol solution, then add 1 milliliter of 5 mol / liter zinc chloride aqueous solution and 5 milliliters of 5 mol / liter sodium hydroxide aqueous solution successively, at room temperature After stirring and reacting for 30 minutes, 166 microliters of sodium chloroaurate solution with a concentration of 0.125 mol / liter was slowly added dropwise, the color of the solution gradually changed from milky white to purple black, and the reaction was continued for 10-30 minutes to obtain gold / zinc oxide composite nano Cluster colloid solution, after the reaction is finished, centrifuge the gold / zinc oxide composite nano-cluster colloid solution at a speed of 8000 rpm, remove the colorless supernatant in the centrifuge tube, and obtain a purple-black precipitate product, which is ultrasoni...

Embodiment 3

[0030] Preparation of Au / ZnO Composite Nanoclusters with 2 wt% Au Loading

[0031] Under stirring conditions at room temperature, first add 14 milliliters of deionized water to 80 milliliters of ethylene glycol solution, then add 1 milliliter of 5 mol / liter zinc chloride aqueous solution and 5 milliliters of 5 mol / liter sodium hydroxide aqueous solution successively, at room temperature After stirring and reacting for 30 minutes, 332 microliters of sodium chloroaurate solution with a concentration of 0.125 mol / liter was slowly added dropwise. Cluster colloid solution, after the reaction is finished, centrifuge the gold / zinc oxide composite nano-cluster colloid solution at a speed of 8000 rpm, remove the colorless supernatant in the centrifuge tube, and obtain a purple-black precipitate product, which is ultrasonically cleaned with alcohol for 3- 5 times, prepared as Figure 6 Au / ZnO composite nanocluster shown in c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com