Synthesizing method of large-diameter Beta molecular sieve

A synthesis method and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems such as restricting the industrial production and large-scale application of Beta molecular sieve, increasing the burden of industrial production in economy and environment, and difficult to separate the solid-liquid separation of molecular sieve slurry. The effect of improving gel reaction rate, improving market value and economic value, and improving industrial production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

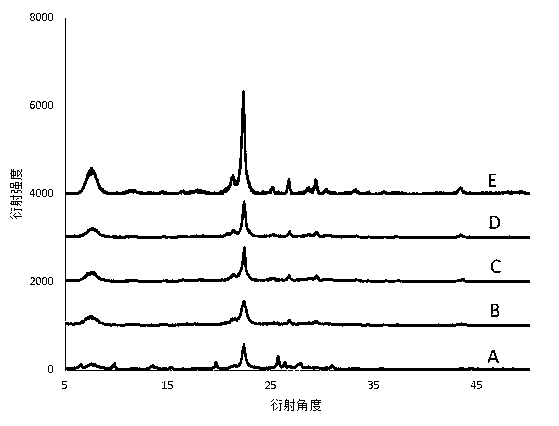

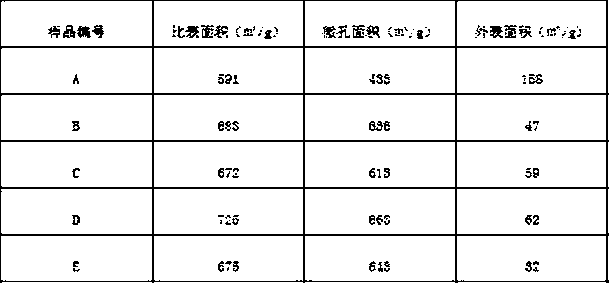

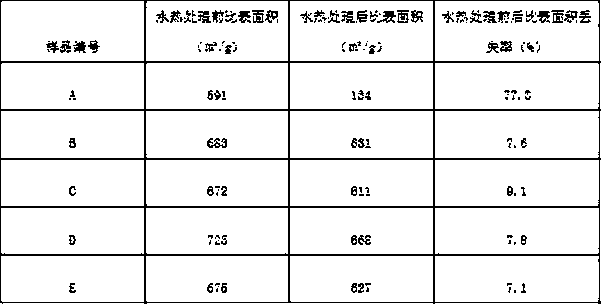

Image

Examples

Embodiment 1

[0039] A kind of synthetic method of large particle diameter Beta molecular sieve, comprises the following steps:

[0040] (1) Gel preparation: Add 1767.6 g of 25wt% tetraethylammonium hydroxide (template agent R) aqueous solution and 600g of 40wt% sodium hydroxide aqueous solution into the container, and stir in a water bath at 30°C for 20 minutes. Add 2571.4g alkaline silica sol (35wt% SiO 2 content), stirred for 40 min. Then add 399.4g of aluminum sulfate octadecahydrate and 2042.8g of water to prepare a mixed solution, keep stirring at 25°C for 4 hours to obtain a gel;

[0041] (2) Crystallization: heat the gel up to 165°C at a heating rate of 25°C / h and keep it warm for 84 hours. Stir at a constant speed of 100r / min while heating up. After the crystallization is completed, suction filter and wash with deionized water. Washing to pH = 7.0, drying at 70°C;

[0042] (3) Ammonium exchange and activation: The dried sample was roasted at 10 °C / min at 550 °C for 6 h; after co...

Embodiment 2

[0045] A kind of synthetic method of large particle diameter Beta molecular sieve, comprises the following steps:

[0046] (1) Gel preparation: Add 3314.3g of 20wt% tetraethylammonium hydroxide (template agent R) aqueous solution and 400g of 30wt% sodium hydroxide aqueous solution into the container, and stir in a water bath at 30°C for 15 minutes. Add 3000g of alkaline silica sol (30wt% SiO2 content), and stir for 35 min. Then add 599.8g aluminum sulfate octadecahydrate and 1428.6g water to prepare the original solution, keep stirring at 30°C for 3 h. Add 1.35g of dimethyl carbonate (accelerator), continue to stir for 1 hour, and use a ball mill to grind for 10 minutes to obtain a gel;

[0047] (2) Pre-crystallization: transfer the gel to a hydrothermal reaction kettle, evacuate with a circulating water vacuum pump until the pressure in the kettle is -0.092 MPa, stir the gel at a stirring speed of 100 r / min for 24 hours, and Under high pressure conditions, the temperature w...

Embodiment 3

[0052] A kind of synthetic method of large particle diameter Beta molecular sieve, comprises the following steps:

[0053] (1) Gel preparation: Add 450.2g of 35wt% tetraethylammonium bromide (template agent R) aqueous solution and 800g of 45wt% sodium hydroxide aqueous solution into the container, and stir in a water bath at 15°C for 30min. Add 2250g alkaline silica sol (40wt% SiO 2 content), stirred for 60 min. Then add the original solution prepared by 80g aluminum chloride and 1967.2g water, keep stirring at 15°C for 6 h. Add 88.5g of diethyl carbonate (accelerator), continue stirring for 2 hours, and grind for 30 minutes with a ball mill to obtain a gel;

[0054] (2) Pre-crystallization: transfer the gel to a hydrothermal reaction kettle, evacuate with a circulating water vacuum pump until the pressure inside the kettle is -0.090MPa, stir the gel at a stirring speed of 300 r / min for 6 hours, and then Raise the temperature to 90°C at a heating rate of 10°C / h, and keep it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com