LVT plastic floor and preparation method thereof

A kind of plastic flooring and plasticizing technology, applied in the direction of coating, etc., can solve the problems of damage, the edge of the product is easy to become brittle, etc., and achieve the effect of recovering elasticity, increasing impact resistance and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

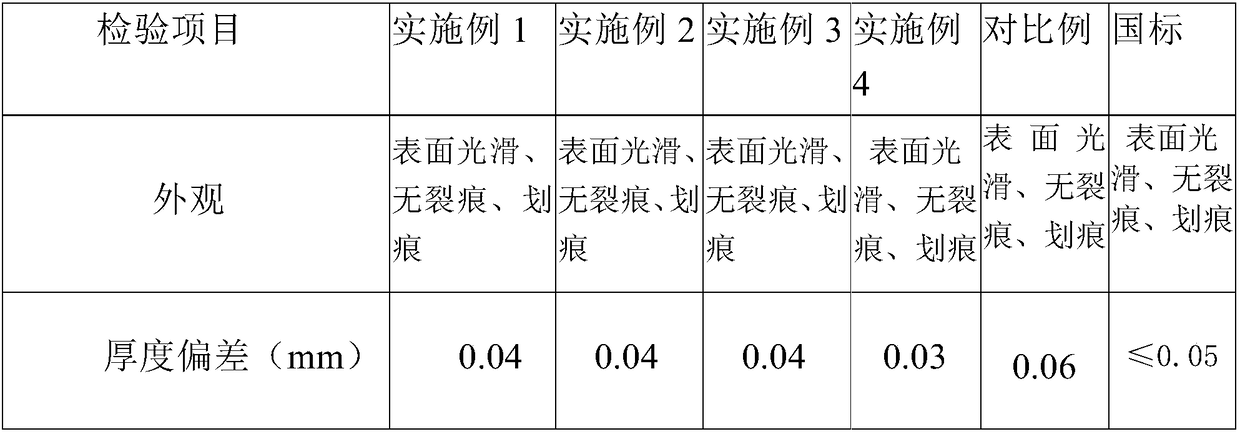

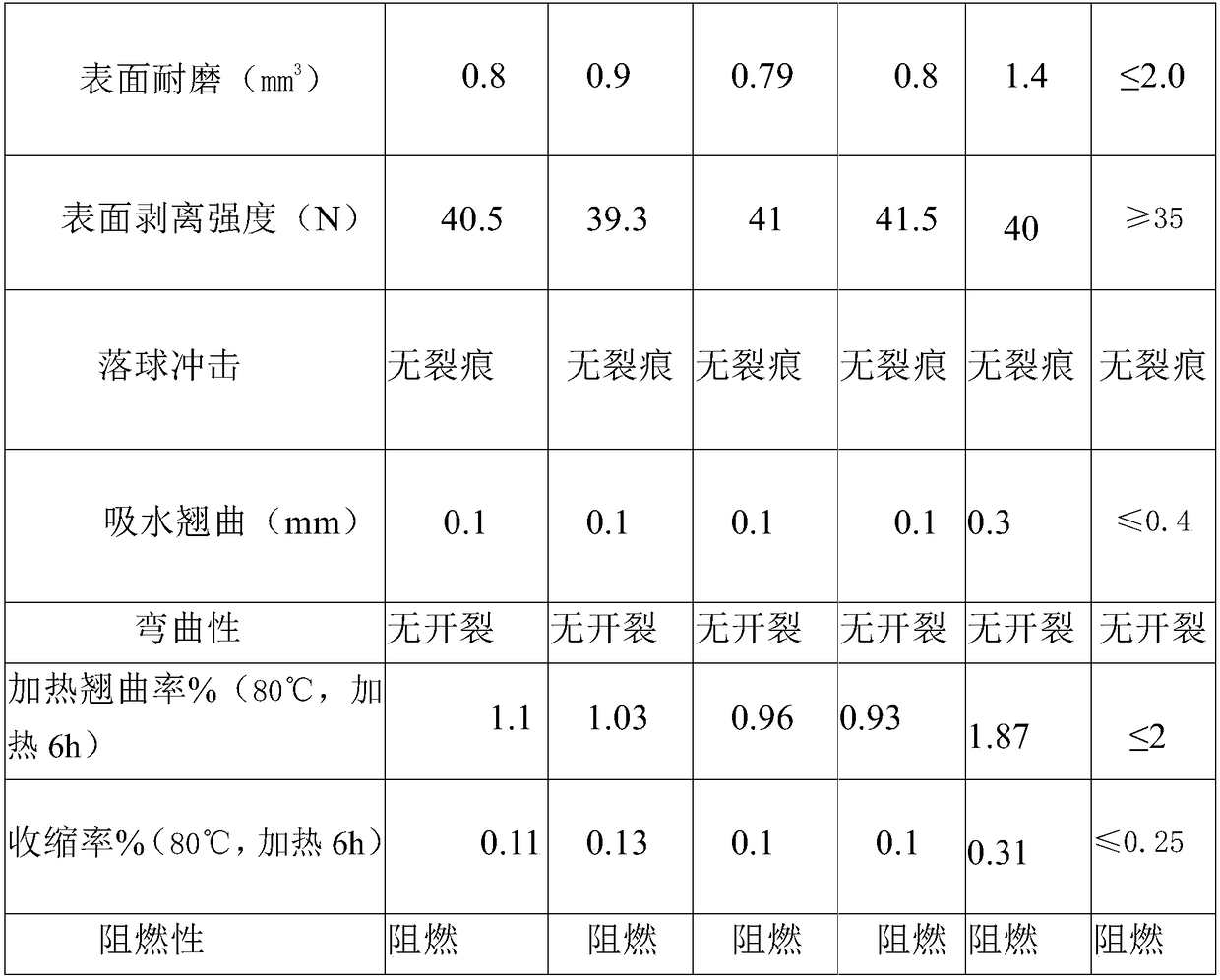

Examples

Embodiment 1

[0034] A kind of LVT plastic floor, comprises the raw material of following parts by weight: 80 parts of PVC resin powder; Particle diameter is 500 mesh ground calcium carbonate 100 parts; 3 parts of dioctyl terephthalate; 4 parts of calcium zinc stabilizer; 2 parts of fatty acid; 0.5 part of carbon black.

[0035] A kind of preparation method of LVT plastic floor, comprises the steps:

[0036] Step 1: Add PVC grease powder, ground calcium carbonate with a particle size of 500 mesh, dioctyl terephthalate, calcium zinc stabilizer and carbon black into a mixer with a rotation speed of 800r / min and mix for 30min, so that the raw materials are mixed evenly. get a mixture;

[0037] Step 2: heat and stir the mixture in an internal mixer with a rotating speed of 280r / min, so that the mixture can be fully fused until the temperature of the mixture reaches 120°C, and stop stirring; after the stirring is completed, the moisture content of the mixture is 0.4%;

[0038] Step 3: Put the ...

Embodiment 2

[0042]A kind of LVT plastic floor, comprises the raw material of following parts by weight: 80 parts of PVC resin powder; Particle diameter is 500 mesh ground calcium carbonate 100 parts; 3 parts of dioctyl terephthalate; 4 parts of calcium zinc stabilizer; 2 parts of fatty acid; 0.5 part of carbon black; 13 parts of modified diatomite;

[0043] Modified diatomite is made from the following raw materials in parts by weight: 10 parts of diatomite, 2 parts of titanium dioxide, 2 parts of lignin, 5 parts of expanded perlite, 3 parts of ferric chloride, n-butyraldehyde-aniline condensate 2 parts and 4 parts of beeswax.

[0044] A kind of preparation method of LVT plastic floor, comprises the steps:

[0045] Step 1: Soak the diatomite in 15% hydrochloric acid solution for 30 minutes, dry the obtained material after suction filtration, mix it with expanded perlite, and calcine it at 750°C for 2 hours, take it out and cool it to room temperature before Mix it with beeswax, grind it...

Embodiment 3

[0052] A kind of LVT plastic floor, comprises the raw material of following parts by weight: 60 parts of PVC resin powder; Particle diameter is 800 mesh ground calcium carbonate 180 parts; Epoxy soybean oil 4 parts; Organotin stabilizer 3.8 parts; Stearic acid 2.1 parts; 0.3 parts of carbon black.

[0053] A kind of preparation method of LVT plastic floor, comprises the steps:

[0054] Step 1: Add PVC powder, ground calcium carbonate with a particle size of 800 mesh, epoxy soybean oil, organic tin stabilizer and carbon black into a mixer with a rotation speed of 800r / min and mix for 40min, so that the raw materials are mixed evenly to obtain a mixture;

[0055] Step 2: Place the mixture in an internal mixer with a rotating speed of 280r / min for heating and stirring, so that the mixture can be fully fused until the temperature of the mixture reaches 110°C, and then stop stirring; after the stirring is completed, the moisture content of the mixture is 0.4%;

[0056] Step 3: Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com