Preparation method of silicon dioxide@porous polymer core-shell microspheres with macroporous structure

A technology of silica and core-shell microspheres, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve problems such as limited application and narrow application range of silanol, and achieve easy Control and amplification, expansion of acid and alkali resistance, easy surface modification and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

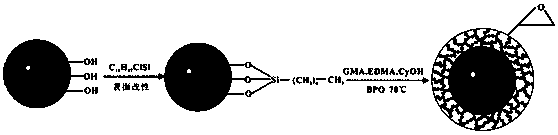

[0026] The preparation method of silica@porous polymer core-shell microspheres comprises the following steps (such as figure 1 ):

[0027] (1) Preparation of non-porous silica microspheres

[0028] First, add 200-300mL of absolute ethanol, appropriate amount of water, ammonia water, and appropriate amount of electrolyte potassium chloride into a clean three-necked bottle, ultrasonically disperse evenly, and stir at room temperature for 30 minutes. Then add an appropriate amount of TEOS dropwise into the above mixed solution, dilute TEOS with absolute ethanol, and the dilution concentration of TEOS is 5-50%. After the dropwise addition, keep the reaction conditions unchanged and continue the reaction for 3h. After the reaction is over, first centrifuge with a centrifuge, 3000r / min for 5 minutes, and use G 5 filter with a glass sand core funnel, wash with distilled water until neutral, then wash with absolute ethanol, and dry in a vacuum oven at 50°C for 12h.

[0029] (2) Su...

Embodiment 2

[0034] (1) Preparation of solid silica microspheres

[0035] According to reference [H. Nakabayashi, A. Yamada, M. Noba, Y. Kobayashi, M. Konno, D. Nagao, Langmuir 26 (2010) 7512-7515] preparation of micron-sized silica solid microspheres, a typical method For: Preparation of liquid A: Take a clean reagent bottle, add 200-300 mL of absolute ethanol, appropriate amount of water, ammonia water and appropriate amount of electrolyte to make a 300 mL mixed solution, and ultrasonicate for 10 min for later use.

[0036] Preparation of solution B: add an appropriate amount of TEOS and a certain amount of absolute ethanol to make a diluted solution, and ultrasonically for 10 min for later use.

[0037] Add liquid A to a 1000 mL three-necked flask, slowly add liquid B dropwise at a controlled rate within 0.8 mL / min, and react at a certain temperature at a certain stirring speed. After the addition of TEOS is completed, keep the reaction conditions unchanged and continue Reaction 3h.

...

example 2

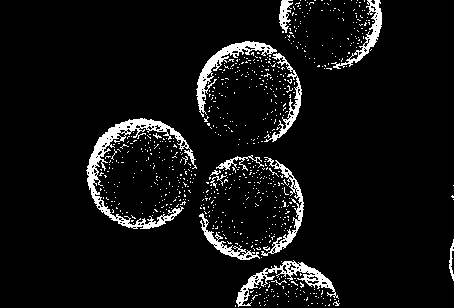

[0044] Take 0.9 g of modified silica gel microspheres in Example 2, add 60 mL of 0.15% SDS for ultrasonic dispersion for 20 min, then add 30 mL of 5% PVA for ultrasonic dispersion for 10 min, and stir at a medium speed at 30 °C. Next, disperse 0.05 g of BPO, 0.9 mL of GMA, 0.9 mL of EDMA, and 1.8 mL of butyl levulinate into a mixed solution of 20 mL of SDS and 10 mL of PVA, and ultrasonically emulsify until uniformly dispersed. Then add the dispersed monomer mixed solution dropwise into the silica gel suspension solution at low rotational speed. React at 30°C for 6 hours. Then pass nitrogen gas for 30 minutes, raise the temperature to 70°C, and continue the reaction for 12 hours. The obtained product is centrifuged three times at 2000 rpm with deionized water, and then washed with a large amount of hot water until the filtrate has no foam, and finally washed once with absolute ethanol. Dry overnight at 60°C. The morphology and pore size distribution of the microspheres are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com