Compound microbial film-coated slow-release fertilizer and preparation method thereof

A technology of compound microorganisms and long-acting fertilizers, applied in urea compound fertilizers, fertilizer mixtures, layered/coated fertilizers, etc., can solve the problem of farmland ecological environment, soil physical and chemical properties and soil microbial flora destruction, and unreasonable fertilizer application environment. , reducing the quality of agricultural products, etc., to achieve the effects of improving the soil micro-ecological environment, reducing leaching losses, and outstanding fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

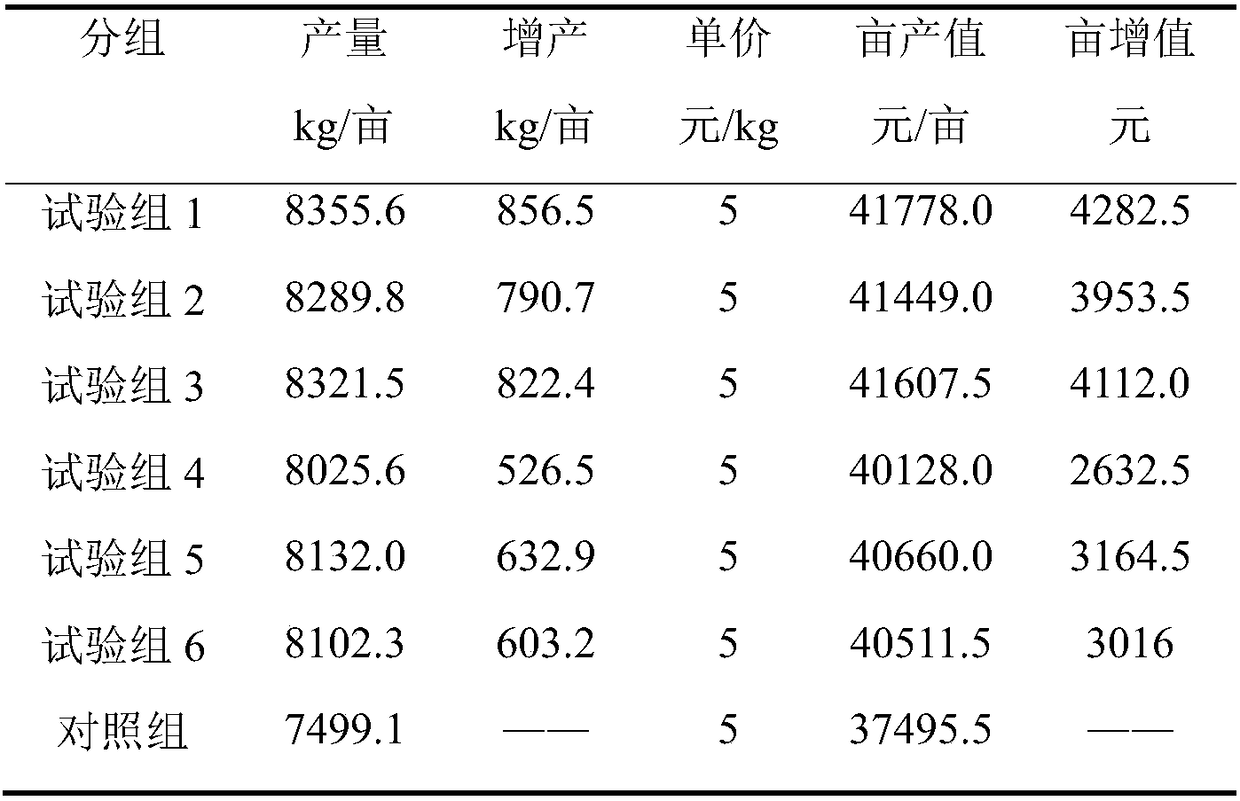

Examples

Embodiment 1

[0034] A compound microorganism-coated long-acting fertilizer is prepared from the following raw materials in parts by weight: 110 parts of fertilizer core, 2 parts of coating layer, and 6 parts of composite microorganism layer;

[0035] The fertilizer core is made from the following raw materials in parts by weight: 50 parts of urea, 10 parts of ammonium bicarbonate, 3 parts of ammonium chloride, 14 parts of potassium nitrate, 5 parts of double superphosphate, 14 parts of potassium sulfate, molybdic acid 1 part of ammonium, 4 parts of magnesium sulfate, 0.3 part of trace elements, 2 parts of porous magnetic chitosan microspheres, 1 part of synergist;

[0036] The coating layer is made of the following raw materials in parts by weight: 4 parts of gelatin, 1 part of glucomannan, 7 parts of polyvinyl alcohol, 30 parts of urea, 1 part of formaldehyde, and 45 parts of water;

[0037] The composite microbial agent is prepared from Bacillus licheniformis, Streptomyces albicans and S...

Embodiment 2

[0052] A compound microbial coating type long-acting fertilizer is prepared from the following raw materials in parts by weight: 100 parts of fertilizer core, 3 parts of coating layer, and 7 parts of composite microbial layer;

[0053] The fertilizer core is made from the following raw materials in parts by weight: 60 parts of urea, 8 parts of ammonium bicarbonate, 2 parts of ammonium chloride, 16 parts of potassium nitrate, 6 parts of double superphosphate, 12 parts of potassium sulfate, molybdic acid 1 part of ammonium, 3 parts of magnesium sulfate, 0.05 part of trace elements, 1 part of porous magnetic chitosan microspheres, 1 part of synergist;

[0054] The coating layer is made of the following raw materials in parts by weight: 3 parts of gelatin, 1 part of glucomannan, 8 parts of polyvinyl alcohol, 20 parts of urea, 1.2 parts of formaldehyde, and 35 parts of water;

[0055] The composite microbial bacterial agent is prepared from Bacillus licheniformis, Streptomyces albi...

Embodiment 3

[0060] A compound microorganism-coated long-acting fertilizer is prepared from the following raw materials in parts by weight: 120 parts of fertilizer core, 3 parts of coating layer, and 4 parts of composite microorganism layer;

[0061] The fertilizer core is made from the following raw materials in parts by weight: 40 parts of urea, 12 parts of ammonium bicarbonate, 4 parts of ammonium chloride, 12 parts of potassium nitrate, 4 parts of double superphosphate, 16 parts of potassium sulfate, molybdic acid 1 part of ammonium, 5 parts of magnesium sulfate, 0.5 part of trace elements, 3 parts of porous magnetic chitosan microspheres, 1 part of synergist;

[0062] The coating layer is made of the following raw materials in parts by weight: 5 parts of gelatin, 1 part of glucomannan, 6 parts of polyvinyl alcohol, 40 parts of urea, 0.8 parts of formaldehyde, and 55 parts of water;

[0063] The composite microbial bacterial agent is prepared from Bacillus licheniformis, Streptomyces a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com