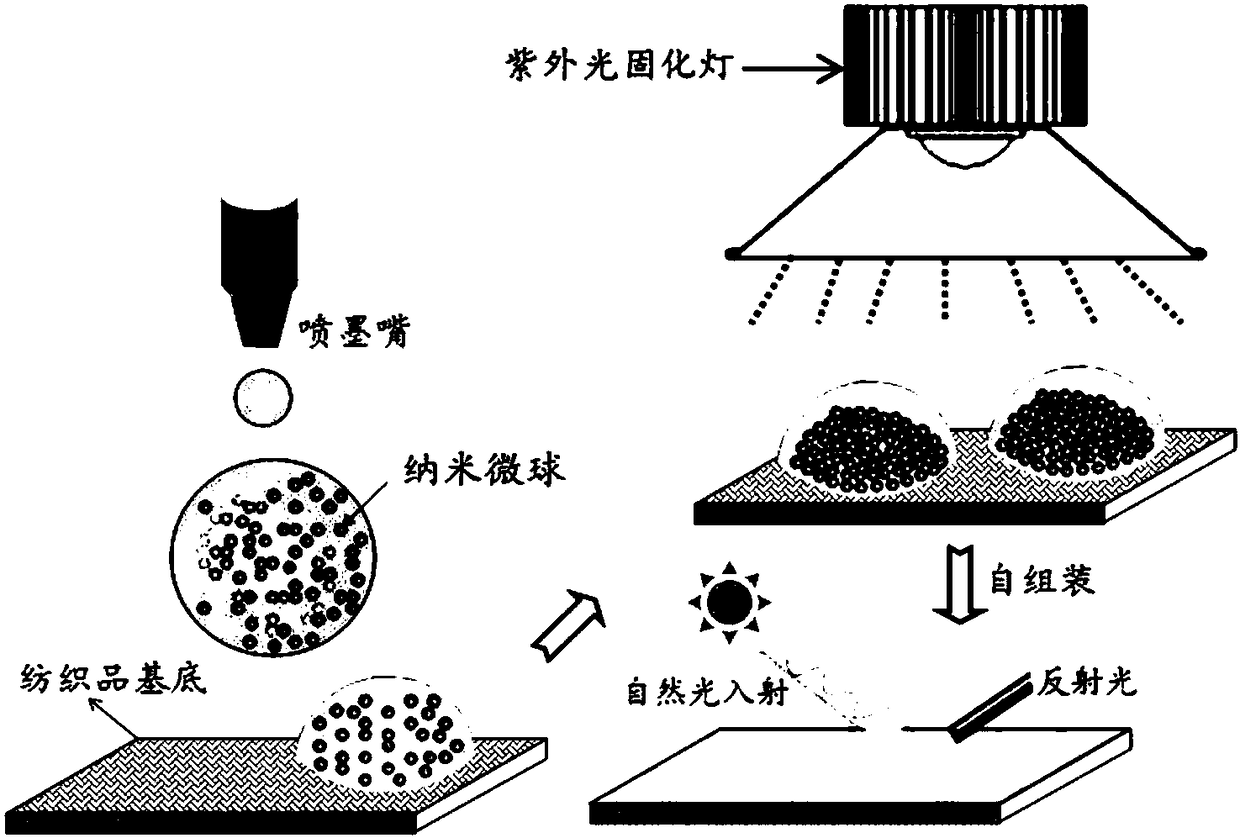

Method for preparing high-stability patterned photonic-crystal coloring structure on surface of textile substrate by utilizing ultraviolet-light curing technology

A technology of substrate surface and curing technology, applied in the field of photonic crystal preparation, can solve the problems of structural color durability difficult to meet the requirements of coloring, photonic crystal structure is easily damaged, poor stability, etc., to achieve easy implementation, guaranteed durability, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

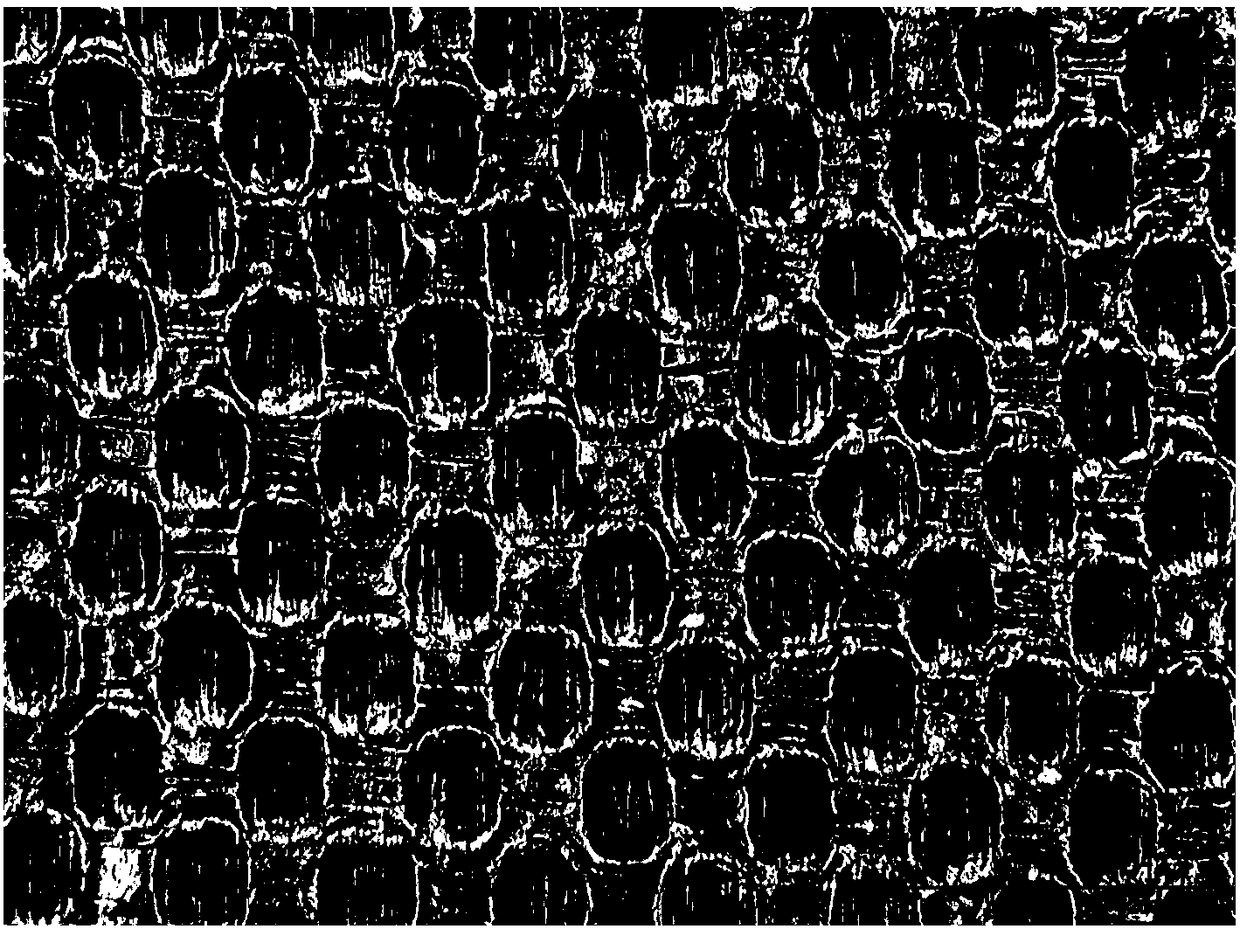

Embodiment 1

[0040] At room temperature, 15% (in terms of solid content) of silicon dioxide (SiO) with a particle size of 200 nm and a monodispersity index (PDI) of 0.02 2 ) nanospheres, 3% structural fixative hydroxyethyl acrylate (HEA), 0.09% photoinitiator phenylbis(2,4,6-trimethylbenzoyl) phosphine oxide, 0.5% coffee ring inhibitor Agent ethylene glycol, 0.1% pH regulator hydrochloric acid and 0.1% humectant glycerin were mixed, and then ultrasonically dispersed for 15 minutes to obtain a photocurable structural color-producing ink; the ink was added to the ink cartridge of the numerically controlled ink distribution system, and the Print patterns and parameters, apply ink on the black cotton fabric that has been pre-treated with water and oil repellency; place the textile with structural color ink under a UV curing lamp with a center wavelength of 365nm and a power of 250W for 480s, A blue photonic crystal chromogenic structure with good stability is obtained. The obtained photonic c...

Embodiment 2

[0042] At room temperature, 10% (in terms of solid content) of cuprous oxide (Cu) with a particle size of 250 nm and a monodispersity index (PDI) of 0.07 2 O) Nanospheres, 2% structure fixative hydroxypropyl acrylate (HPA), 0.06% photoinitiator (2,4,6-trimethylbenzoyl) diphenylphosphine oxide, 0.3% coffee ring Inhibitor formamide, 0.2% pH regulator glacial acetic acid and 0.3% humectant polyethylene glycol were mixed, and then ultrasonically dispersed for 15 minutes to obtain photocurable structural color-producing ink; the ink was added to the ink cartridge of the numerical control ink distribution system, passed Set the printing pattern and parameters, and apply ink on the black polyester-cotton fabric that has been pretreated with water and oil repellency; put the textile with structural color ink on it and cure it under a UV curing lamp with a center wavelength of 365nm and a power of 250W After treatment for 450s, an orange-yellow photonic crystal chromogenic structure wi...

Embodiment 3

[0044]At room temperature, 10% (in terms of solid content) of poly(styrene-methacrylic acid (PSt-MAA) nanospheres with a particle size of 300 nm and a monodispersity index (PDI) of 0.02, and 2% of a structure-fixing agent β-hydroxyethyl methacrylate (HEMA), 0.06% photoinitiator 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, 0.3 % coffee ring inhibitor ethylene glycol, 0.1% pH regulator sodium hydroxide and 0.2% humectant polyethylene glycol were mixed, and then ultrasonically dispersed for 15 minutes to obtain photocurable structural color-producing ink; the ink was added to the CNC ink distribution system In the ink cartridge, by setting the printing pattern and parameters, the ink is applied on the black silk fabric that has been pretreated with water and oil repellency; the textile with the structural color ink is placed in the ultraviolet light with a center wavelength of 365nm and a power of 250W After curing under the curing lamp for 420s, a red photonic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com