Catalyst and preparation method thereof and method for preparing 3-hydroxypropionaldehyde

A technology of hydroxypropanal and catalyst, which is applied in the field of 3-hydroxypropanal in the hydration reaction of acrolein, which can solve the problems of decreased conversion rate, increased concentration of polymerization inhibitor, and side reactions, so as to prevent catalyst deactivation and ensure conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

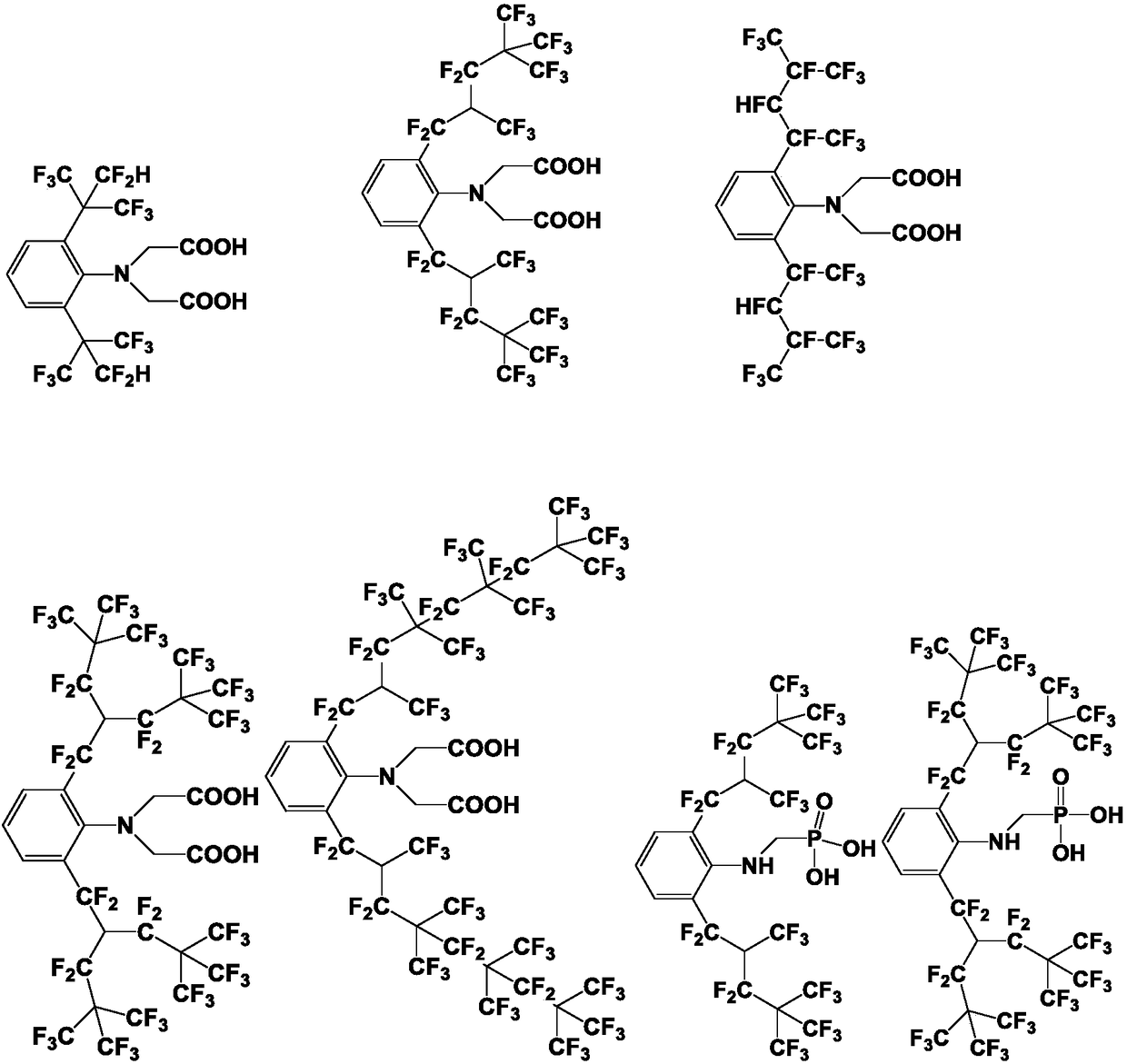

[0070] The structural formula of catalyst 1 is Its preparation method is as follows:

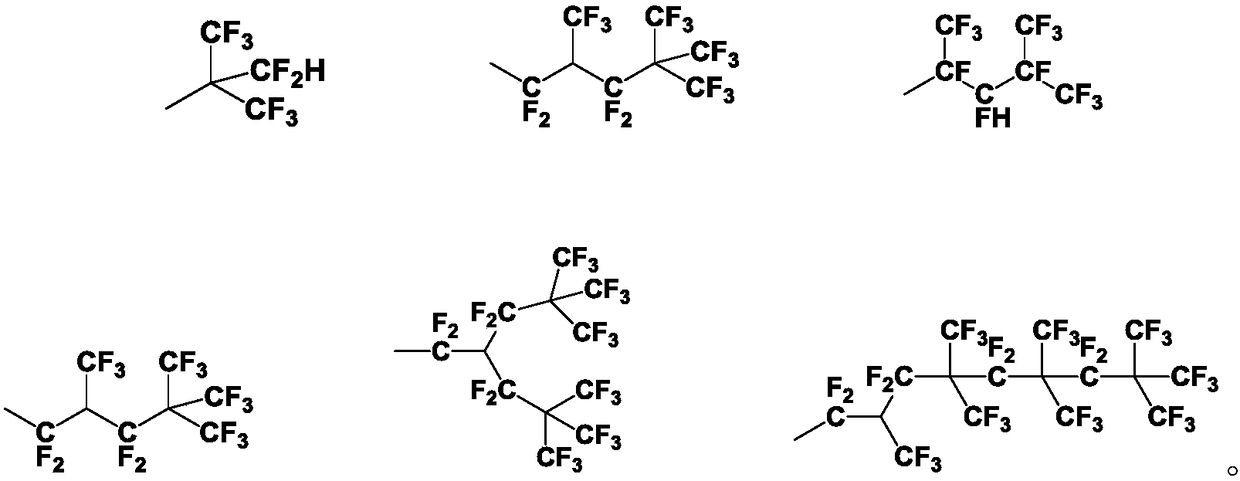

[0071] 1) Add 5wt% KHF in the reactor 2 DMF solvent, the temperature was raised to 80 ° C, and hexafluoropropylene was introduced and continuously replenished to maintain the pressure at 2 MPaG. After 5 hours of reaction, the unreacted hexafluoropropylene was depressurized and emptied, and the liquid phase reactant was added with water to make it Layering, the oil phase is a hexafluoropropylene oligomer, which is separated by rectification to obtain a hexafluoropropylene dimer (C6);

[0072] 2) Add aniline, aluminum powder and aluminum trichloride into a high-pressure stirred tank, the molar ratio of aluminum powder and aluminum trichloride is 3:1, the molar ratio of aluminum trichloride to aniline is 0.1, and react at 170°C After 1.5 hours, the generated hydrogen was evacuated and replaced with nitrogen. After the reactor was heated to 270° C., the hexafluoropropylene dimer prepared in s...

Embodiment 2

[0077] The structural formula of catalyst 2 is Its preparation method is as follows:

[0078] 1) Add aniline, aluminum powder and aluminum trichloride to a high-pressure stirred tank, the molar ratio of aluminum powder to aluminum trichloride is 3:1, the molar ratio of aluminum trichloride to aniline is 0.1, and react at 150°C After 0.5h, the generated hydrogen was evacuated and replaced with nitrogen. After heating the reactor to 250°C, octafluoroisobutene was introduced into the reactor. The molar ratio of octafluoroisobutene to aniline was 2.1. Quench the catalyst with 25 times the molar amount of aluminum to quench the catalyst and make the reaction solution layered. The oil phase is a branched chain alkylaniline substituted by octafluoroisobutane (the selectivity of 2,6-substituted is 83%). Distillation obtains 2,6-difluoro branched chain alkylaniline;

[0079] 2) 2,6-difluoro-branched alkylaniline reacted with 2.1 times the molar amount of sodium chloroacetate and 1.1...

Embodiment 3

[0083] The structural formula of catalyst 3 is Its preparation method is as follows:

[0084] 1) Add 3wt% KHF in the reactor 2 DMF solvent, the temperature was raised to 100 °C, and octafluoroisobutene was introduced and continuously replenished to maintain the pressure at 4MPaG. After 3 hours of reaction, the unreacted octafluoroisobutene was depressurized and emptied, and the liquid phase reactant was added with water to make it Separation, the oil phase is octafluoroisobutene oligomer, separated by rectification to obtain octafluoroisobutene dimer (C8), trimer (C12), tetramer (C16);

[0085] 2) Add aniline, aluminum powder and aluminum trichloride to a high-pressure stirred tank, the molar ratio of aluminum powder and aluminum trichloride is 3:1, the molar ratio of aluminum trichloride to aniline is 0.15, and react at 190°C After 3 hours, the generated hydrogen was evacuated and replaced with nitrogen, and the temperature of the reactor was raised to 290°C, and the octaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com