Preparation method of lithium iron phosphate with high conductivity and high tap density

A lithium iron phosphate and tap density technology, applied in the field of electrochemical power supply material preparation, can solve the problems of insufficient material coating and uniform doping, limited improvement in electrical conductivity, reduced tap density, etc. The effect of uniform doping and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

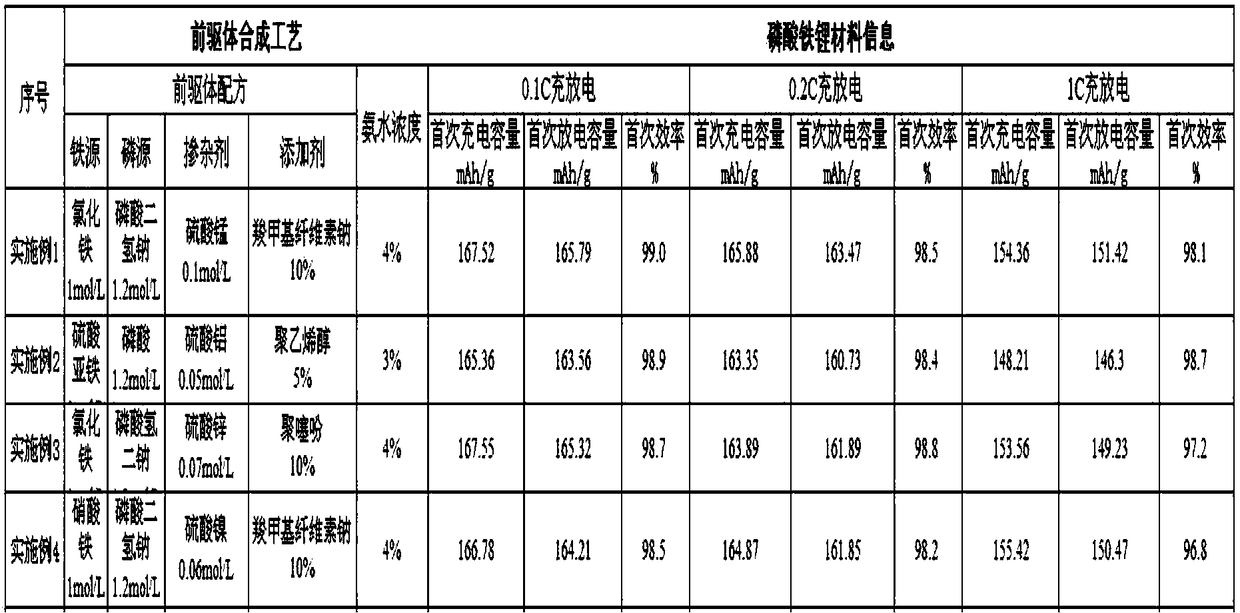

Embodiment 1

[0020] A preparation method of lithium iron phosphate with high electrical conductivity and high tap density, comprising the following steps:

[0021] (1) First ferric chloride, sodium dihydrogen phosphate, manganese sulfate and sodium carboxymethyl cellulose solution are prepared as a mixed solution, wherein the concentration of ferric chloride solution is 1mol / L and sodium dihydrogen phosphate concentration is 1.2mol / L, sulfuric acid The manganese concentration is 0.1mol / L, and the amount of sodium carboxymethylcellulose added is 10% of the mass of ferric chloride;

[0022] (2) Synthesis of spherical metal ion doped iron phosphate precursor:

[0023] ① Slowly drop the mixed solution and 4% ammonia water at a flow rate of 200ml / h into a magnetic stirring container with pH=1.7 and 40ml of sodium dihydrogen phosphate solution as the bottom liquid, and at the same time control the pH value of the mixed solution by dropping ammonia water 1.3, stop the titration and continue to s...

Embodiment 2

[0029] A preparation method of lithium iron phosphate with high electrical conductivity and high tap density, comprising the following steps:

[0030] (1) Ferrous sulfate, phosphoric acid, aluminum sulfate and sodium carboxymethyl cellulose solution are prepared mixed solution earlier, wherein ferrous sulfate solution concentration is 1mol / L and phosphoric acid concentration 1.2mol / L, aluminum sulfate concentration 0.05mol / L , the amount of polyvinyl alcohol is 5% of the quality of ferrous sulfate;

[0031] (2) Synthesis of spherical metal ion doped iron phosphate precursor:

[0032] ① Slowly drop the mixed solution and 3% ammonia water at a flow rate of 100ml / h into a magnetic stirring container equipped with pH=1.3 and 30ml phosphoric acid solution as the bottom liquid, and at the same time control the pH value of the mixed solution to 1.4 by dropping ammonia water , the mixed solution drops or the volume of the mixed material reaches two-thirds of the reaction vessel, stop...

Embodiment 3

[0038] A preparation method of lithium iron phosphate with high electrical conductivity and high tap density, comprising the following steps:

[0039] (1) First ferric chloride, disodium hydrogen phosphate, zinc sulfate and sodium carboxymethyl cellulose solution are prepared as a mixed solution, wherein the concentration of ferric chloride solution is 1mol / L and the concentration of disodium hydrogen phosphate is 1.2mol / L, sulfuric acid The concentration of zinc is 0.07mol / L, and the amount of polythiophene added is 10% of the mass of ferric chloride;

[0040] (2) Synthesis of spherical metal ion doped iron phosphate precursor:

[0041] ① Slowly drop the mixed solution and 4% ammonia water at a flow rate of 150ml / h into a magnetic stirring container equipped with a pH=1.7, 35ml disodium hydrogen phosphate solution as the bottom liquid, and at the same time control the mixed solution by dropping ammonia water When the pH value is 1.2, stop the titration and continue to stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com