Preparation and application of gel polymer electrolyte

A technology of gel polymers and electrolytes, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problems of low ionic conductivity and insufficient mechanical strength, and achieve high ionic conductivity and high ionic conductivity efficiency, interface stability, and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

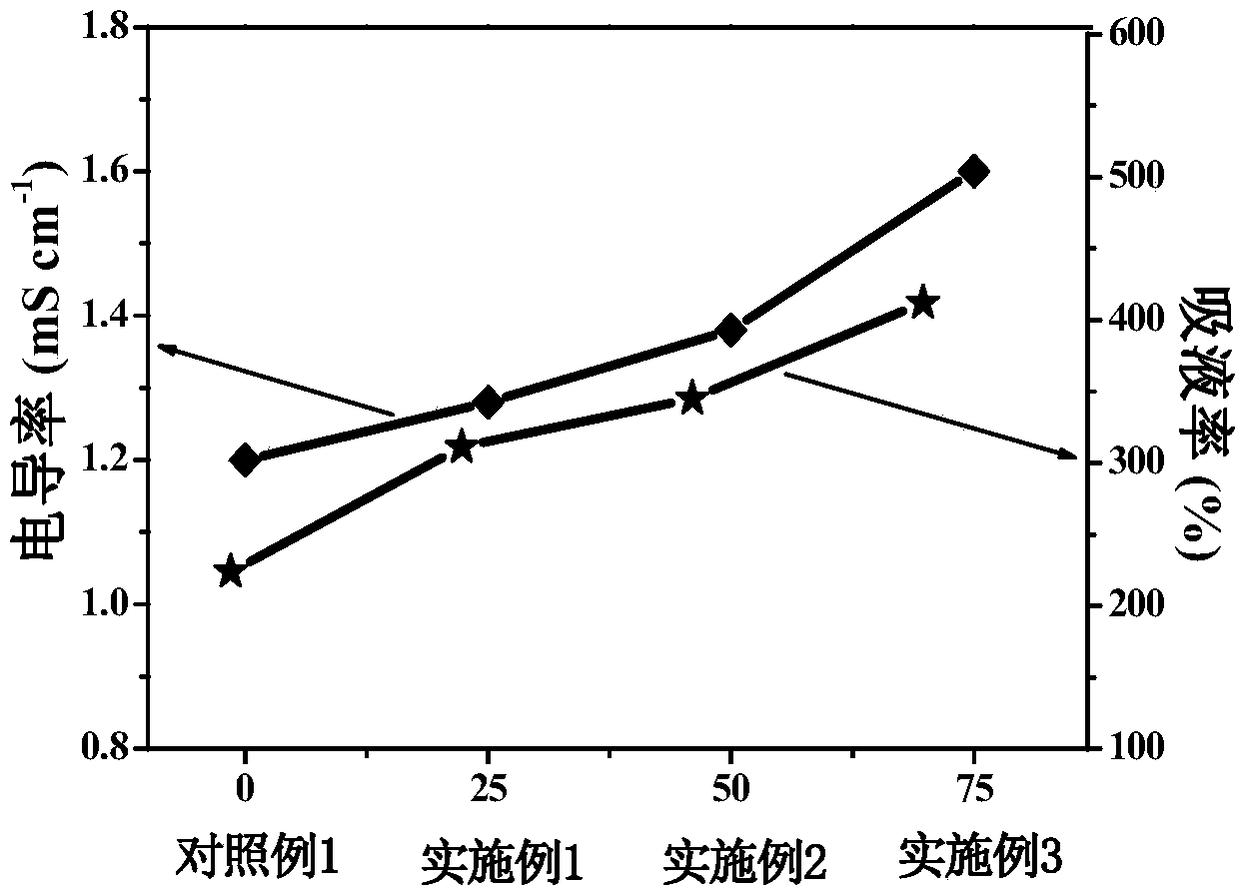

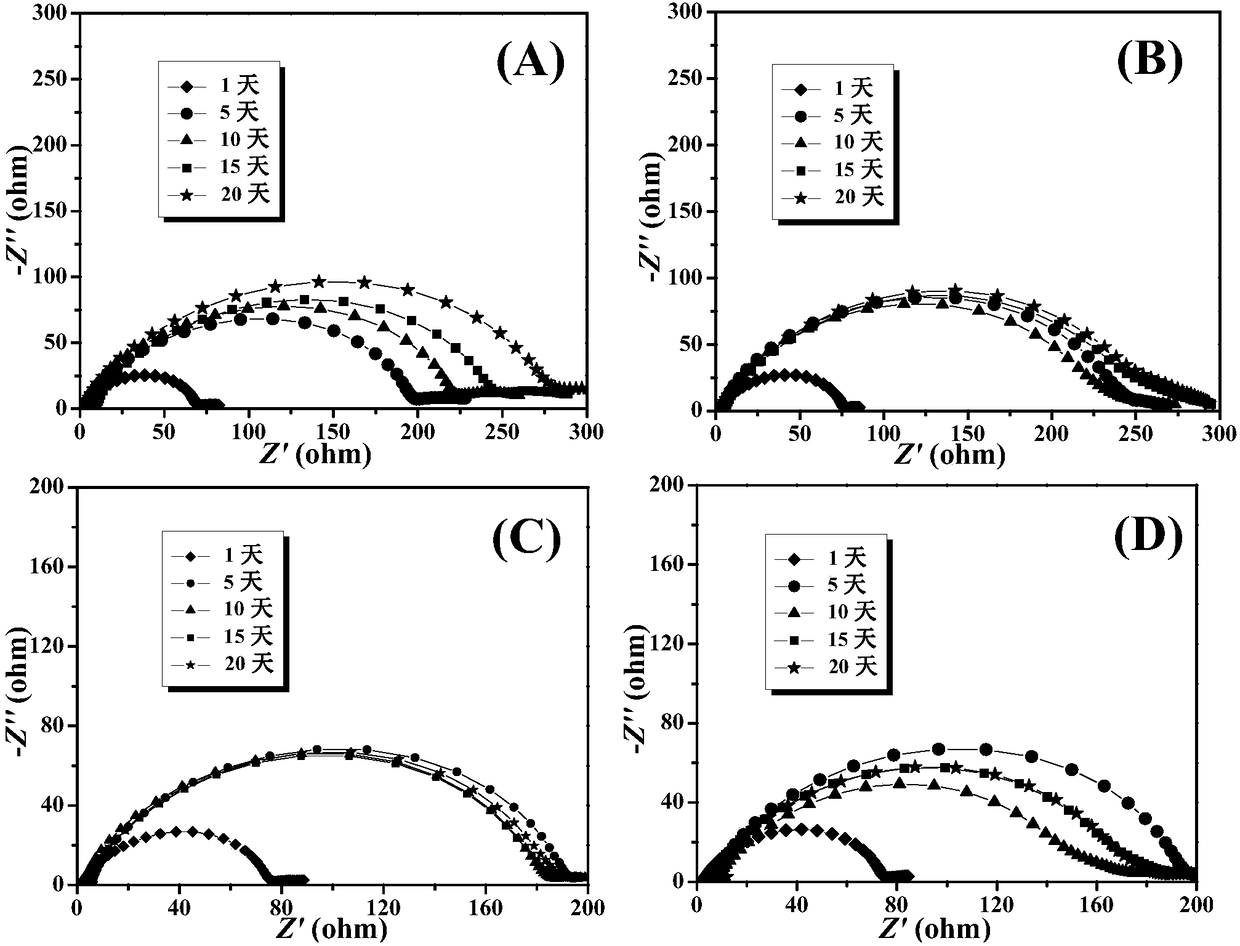

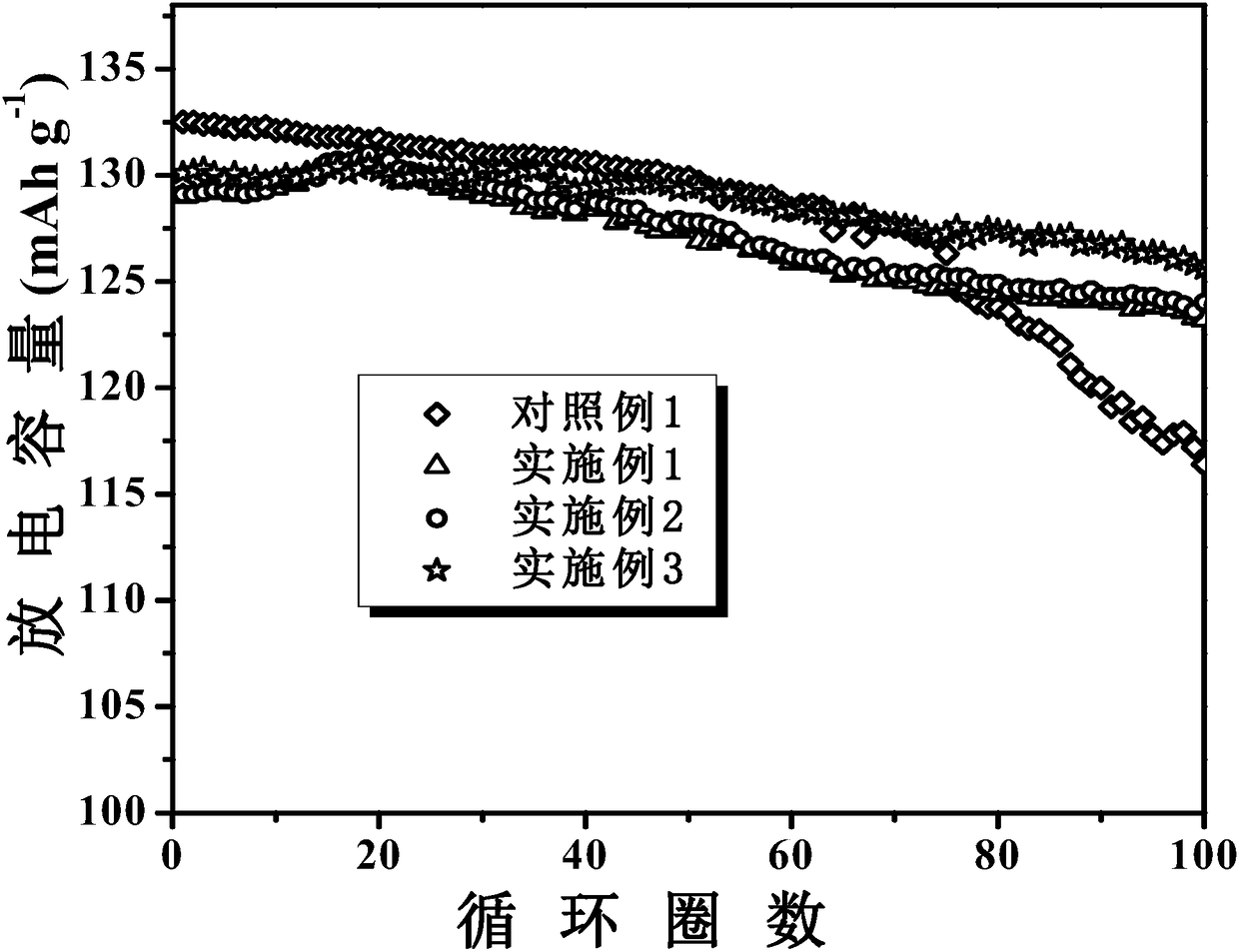

Embodiment 1

[0038] (1) The temperature of the oil bath was kept at 40°C. P(VdF-HFP) and P(MEMA) with a mass ratio of 3:1 were added to a three-necked flask, and acetone and dimethylacetamide with a mass ratio of 7:3 were added ( DMAC) mixed solvent, mechanically continuously stirred for 1 h to fully dissolve it to obtain a gel polymer solution with a mass fraction of 16%, wherein the stirring speed was 400r / min.

[0039] (2) Put the polymer solution obtained in step (1) into the syringe of the propulsion device of the electrospinning machine, use the PE film as a support, and spin in an electrostatic field with a voltage of 18kV and a receiving distance of 20cm to obtain a bismuth The surface of the porous diaphragm coated with the same amount of polymer fibers was transferred to a vacuum drying oven at 60°C for 12 hours, and the thickness of the film was 45-50 μm.

[0040] (3) Process according to step (3) of Example 1.

[0041] (4) Process according to step (4) of Example 1.

Embodiment 2

[0043] (1) The temperature of the oil bath was kept at 40°C. P(VdF-HFP) and P(MEMA) with a mass ratio of 1:1 were added to a three-necked flask, and acetone and dimethylacetamide with a mass ratio of 7:3 were added ( DMAC) mixed solvent, mechanically continuously stirred for 1 h to fully dissolve it to obtain a gel polymer solution with a mass fraction of 16%, wherein the stirring speed was 300 r / min.

[0044] (2) Put the polymer solution obtained in step (1) into the syringe of the propulsion device of the electrospinning machine, use the PE film as a support, and spin in an electrostatic field with a voltage of 16kV and a receiving distance of 20cm to obtain a double The surface of the porous diaphragm coated with the same amount of polymer fibers was transferred to a vacuum drying oven at 60°C for 10 hours, and the thickness of the film was 45-50 μm.

[0045] (3) Process according to step (3) of Example 1.

[0046] (4) Process according to step (4) of Example 1.

Embodiment 3

[0048] (1) The oil bath was kept at a constant temperature of 40°C. P(VdF-HFP) and P(MEMA) with a mass ratio of 1:3 were added to a three-necked flask, and acetone and dimethylacetamide with a mass ratio of 7:3 were added ( DMAC) mixed solvent, mechanically continuously stirred for 1 h to fully dissolve it to obtain a gel polymer solution with a mass fraction of 16%, wherein the stirring speed was 300 r / min.

[0049] (2) Put the polymer solution obtained in step (1) into the syringe of the propulsion device of the electrospinning machine, use the PE film as a support, and spin in an electrostatic field with a voltage of 18kV and a receiving distance of 20cm to obtain a bismuth The surface of the porous diaphragm coated with the same amount of polymer fibers was transferred to a vacuum drying oven at 60°C for 12 hours, and the thickness of the film was 45-50 μm.

[0050] (3) Process according to step (3) of Example 1.

[0051] (4) Process according to step (4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com