Preparation and application of a gel polymer electrolyte

A gel polymer and electrolyte technology, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problems of low ionic conductivity and insufficient mechanical strength, and achieve high ionic conductivity and high ionic conductivity efficiency and interface stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

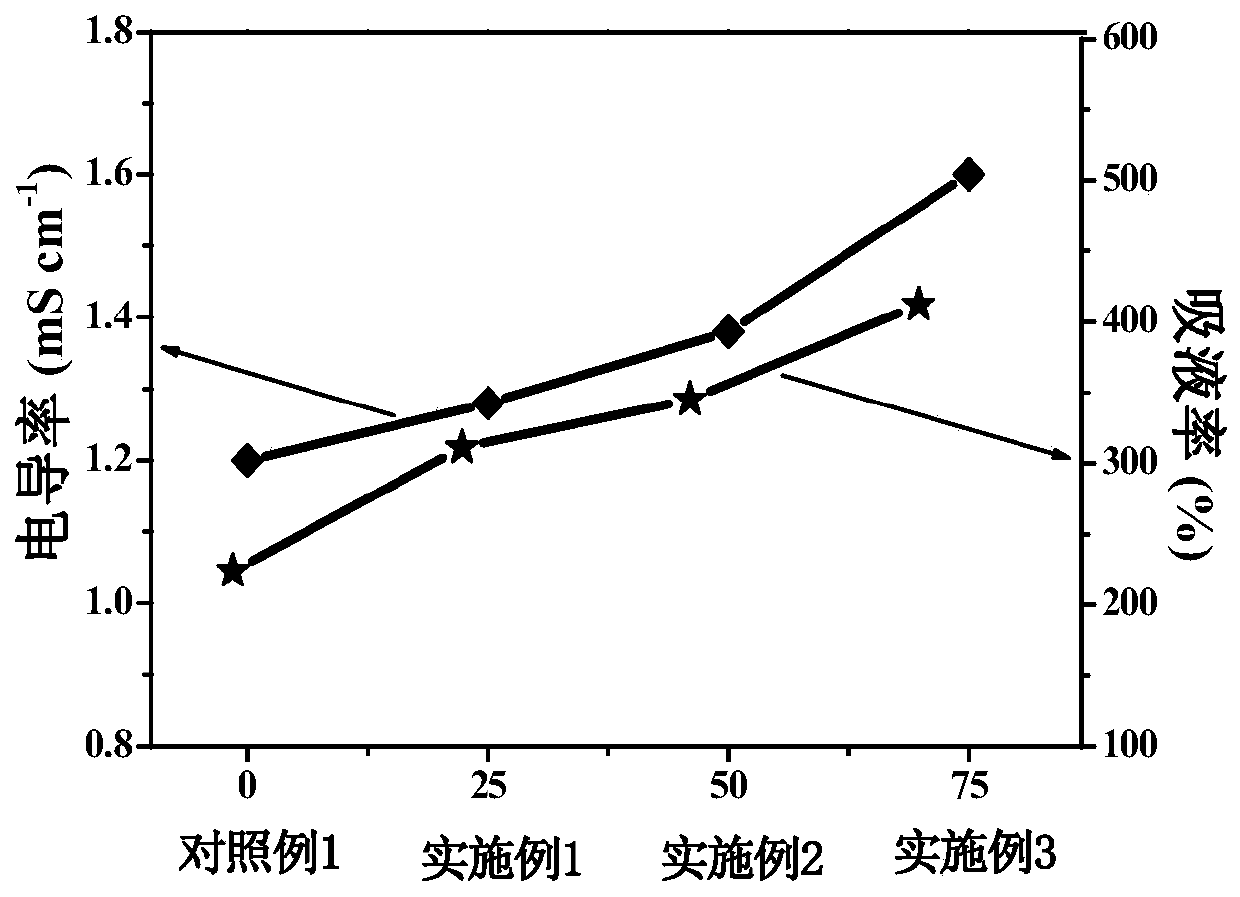

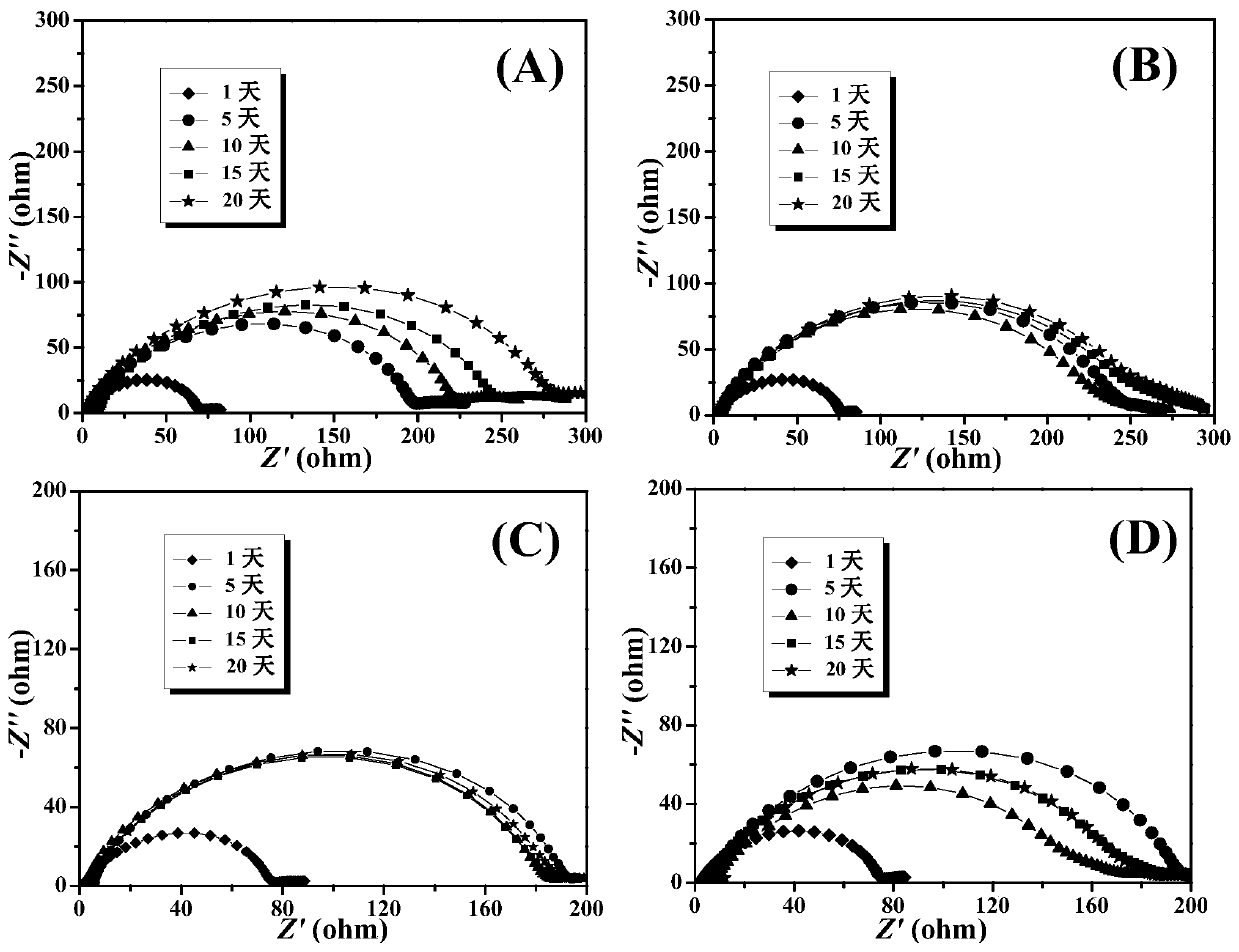

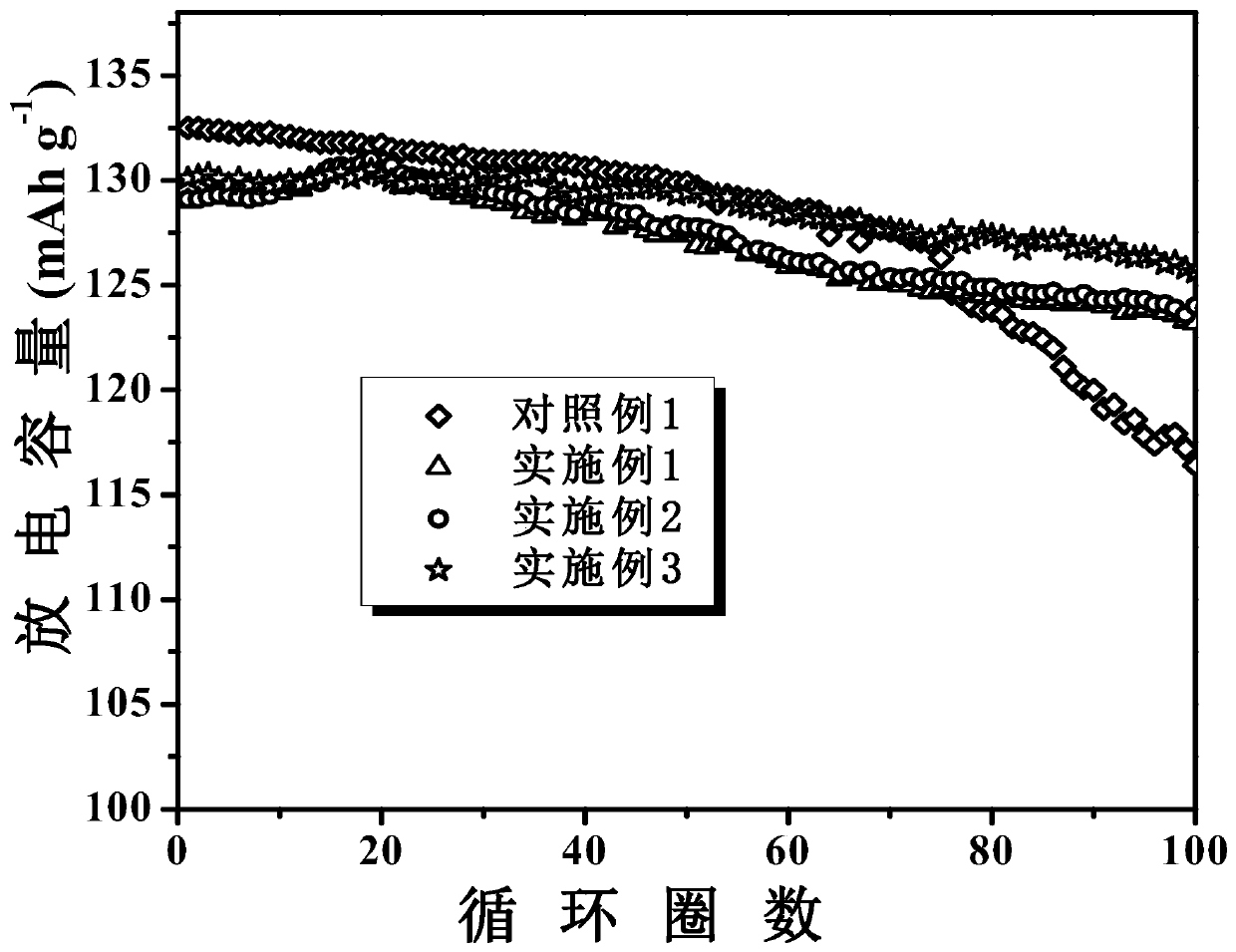

Embodiment 1

[0038] (1) The temperature of the oil bath was kept at 40°C. P(VdF-HFP) and P(MEMA) with a mass ratio of 3:1 were added to a three-necked flask, and acetone and dimethylacetamide with a mass ratio of 7:3 were added ( DMAC) mixed solvent, mechanically continuously stirred for 1 h to fully dissolve it to obtain a gel polymer solution with a mass fraction of 16%, wherein the stirring speed was 400r / min.

[0039] (2) Put the polymer solution obtained in step (1) into the syringe of the propulsion device of the electrospinning machine, use the PE film as a support, and spin in an electrostatic field with a voltage of 18kV and a receiving distance of 20cm to obtain a bismuth The surface of the porous diaphragm coated with the same amount of polymer fibers was transferred to a vacuum drying oven at 60°C for 12 hours, and the thickness of the film was 45-50 μm.

[0040] (3) Process according to step (3) of Example 1.

[0041] (4) Process according to step (4) of Example 1.

Embodiment 2

[0043] (1) The temperature of the oil bath was kept at 40°C. P(VdF-HFP) and P(MEMA) with a mass ratio of 1:1 were added to a three-necked flask, and acetone and dimethylacetamide with a mass ratio of 7:3 were added ( DMAC) mixed solvent, mechanically continuously stirred for 1 h to fully dissolve it to obtain a gel polymer solution with a mass fraction of 16%, wherein the stirring speed was 300 r / min.

[0044] (2) Put the polymer solution obtained in step (1) into the syringe of the propulsion device of the electrospinning machine, use the PE film as a support, and spin in an electrostatic field with a voltage of 16kV and a receiving distance of 20cm to obtain a double The surface of the porous diaphragm coated with the same amount of polymer fibers was transferred to a vacuum drying oven at 60°C for 10 hours, and the thickness of the film was 45-50 μm.

[0045] (3) Process according to step (3) of Example 1.

[0046] (4) Process according to step (4) of Example 1.

Embodiment 3

[0048] (1) The oil bath was kept at a constant temperature of 40°C. P(VdF-HFP) and P(MEMA) with a mass ratio of 1:3 were added to a three-necked flask, and acetone and dimethylacetamide with a mass ratio of 7:3 were added ( DMAC) mixed solvent, mechanically continuously stirred for 1 h to fully dissolve it to obtain a gel polymer solution with a mass fraction of 16%, wherein the stirring speed was 300 r / min.

[0049] (2) Put the polymer solution obtained in step (1) into the syringe of the propulsion device of the electrospinning machine, use the PE film as a support, and spin in an electrostatic field with a voltage of 18kV and a receiving distance of 20cm to obtain a bismuth The surface of the porous diaphragm coated with the same amount of polymer fibers was transferred to a vacuum drying oven at 60°C for 12 hours, and the thickness of the film was 45-50 μm.

[0050] (3) Process according to step (3) of Example 1.

[0051] (4) Process according to step (4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com