Polyester of biological carbonic-ester-contained structure and preparing method and application of biological polyester

A bio-based, carbonate technology, applied in chemical recycling and other directions, can solve problems such as large pollution, poor production conditions, equipment corrosion, etc., and achieve the effects of simple preparation process, excellent hydrolysis resistance, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

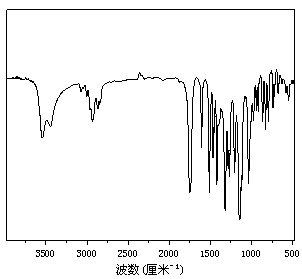

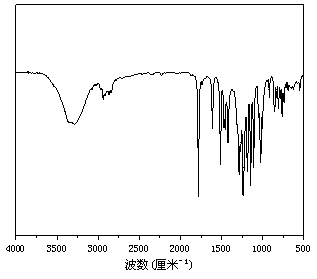

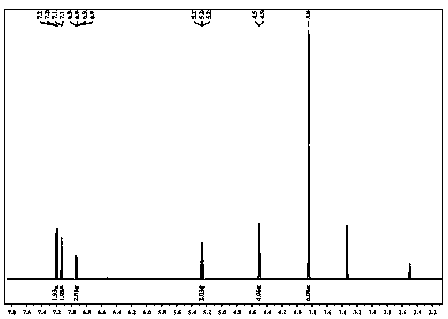

Image

Examples

Embodiment 1

[0052] Embodiment 1: a kind of preparation method of bio-based polyester containing carbonate structure, comprises the following steps:

[0053] (1) Dissolve vanillin and triethylamine in dichloromethane, slowly add triphosgene solution in dichloromethane dropwise under ice bath conditions, the molar ratio of vanillin to triphosgene to triethylamine is 6 :1:7.5, after the dropwise addition is completed, gradually rise to room temperature and react for 5h, wash with 1mol / L dilute hydrochloric acid and water, extract the inorganic phase with dichloromethane, spin dry the solvent, and recrystallize with dichloromethane / n-hexane to obtain Bio-based dialdehyde monomers containing carbonate structure;

[0054] (2) Add sodium borohydride to the tetrahydrofuran solution of the bio-based dialdehyde monomer containing carbonate structure obtained in step (1) in batches under ice-bath conditions, and control the separation between the dialdehyde monomer and sodium borohydride. The molar...

Embodiment 2

[0056] Embodiment 2: a kind of preparation method of bio-based diol polymerizable monomer containing carbonate structure, comprises the following steps:

[0057] (1) Said that syringaldehyde and trimethylamine were dissolved in dichloromethane, and the dichloromethane solution of triphosgene was slowly added dropwise under ice bath conditions, and the molar ratio of syringaldehyde to triphosgene to trimethylamine was 6: 1:6, after the dropwise addition, gradually rise to room temperature and react for 1h, wash with 1mol / L dilute hydrochloric acid and water, extract the inorganic phase with dichloromethane, spin dry the solvent, and recrystallize with dichloromethane / n-hexane to obtain biological A dialdehyde monomer containing a carbonate structure;

[0058] (2) Add sodium borohydride to the tetrahydrofuran solution of the bio-based dialdehyde monomer containing carbonate structure obtained in step (1) in batches under ice-bath conditions, and control the separation between th...

Embodiment 3

[0060] Embodiment 3: a kind of preparation method of bio-based diol polymerizable monomer containing carbonate structure, comprises the following steps:

[0061] (1) Dissolve vanillin and triethylamine in dichloromethane, slowly add triphosgene solution in dichloromethane dropwise under ice bath conditions, the molar ratio of vanillin to triphosgene to triethylamine is 6 : 1:9, after the dropwise addition is completed, gradually rise to room temperature and react for 10h, wash with 1mol / L dilute hydrochloric acid and water, extract the inorganic phase with dichloromethane, spin dry the solvent, and recrystallize with dichloromethane / n-hexane to obtain Bio-based dialdehyde monomers containing carbonate structure;

[0062] (2) Add sodium borohydride to the tetrahydrofuran solution of the bio-based dialdehyde monomer containing carbonate structure obtained in step (1) in batches under ice-bath conditions, and control the separation between the dialdehyde monomer and sodium borohy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com