Copper hydroxychloride nanosheet and preparation method thereof

A copper hydroxychloride and nanosheet technology, applied in copper chloride, copper halide, nanotechnology and other directions, can solve the problems of no efficient progress in the preparation of copper hydroxychloride, few preparation methods, large sample particles, etc. The surface is smooth and flat, the preparation method is simple, and the crystallinity is intact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

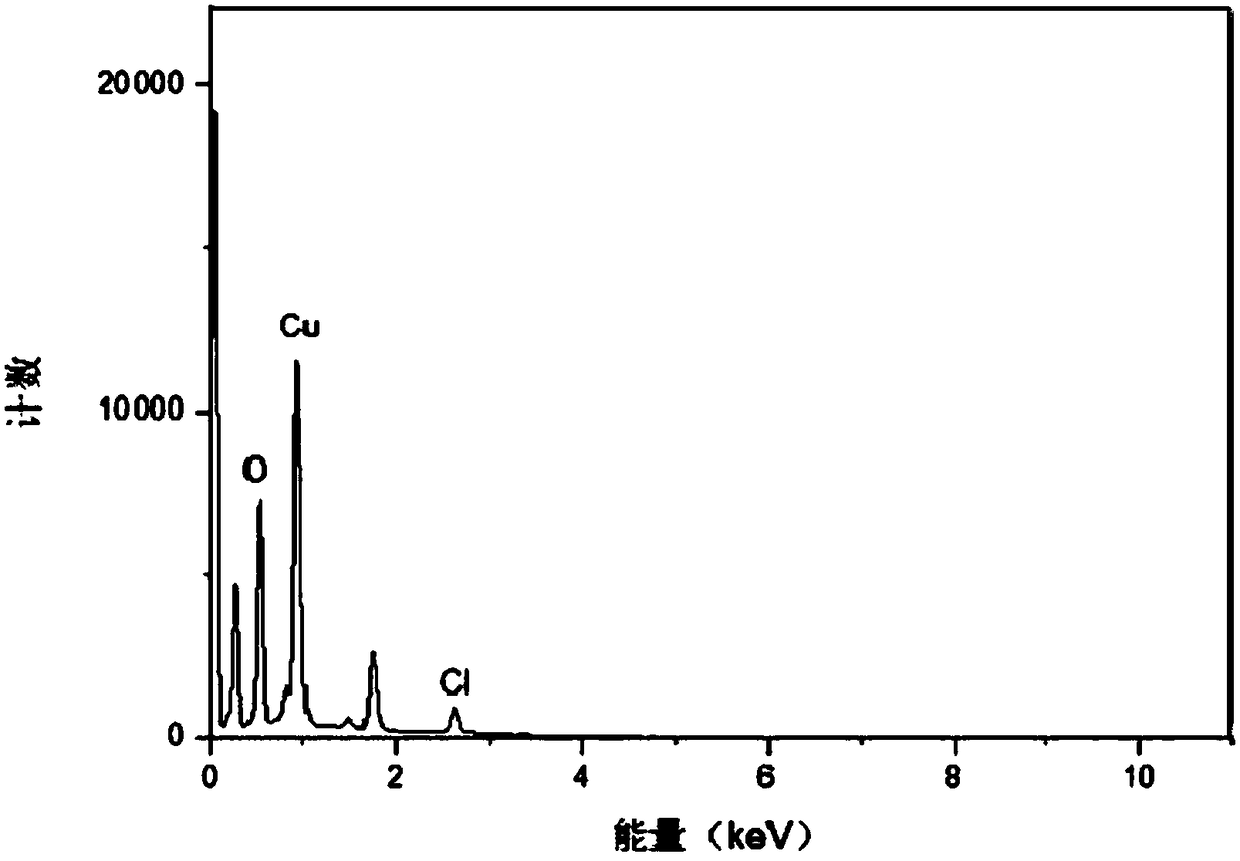

[0031] Embodiment 1 prepares the best Cu 2 (OH) 3 The whole process of Cl nanosheets.

[0032] Copper nitrate (Cu(NO 3 ) 2 ), hexamethylenetetramine (HMT) and sodium chloride (NaCl) as raw materials, first take 0.210g hexamethylenetetramine (HMT) and 0.362g copper nitrate (Cu(NO 3 ) 2 ) into a clean beaker, add 15ml of deionized water and stir in a magnetic stirrer for 15min, add 0.438g of sodium chloride (NaCl) and continue stirring for 10min after the stirring is completed, so that the medicine can fully react, and pour the reacted liquid into Heat in a polytetrafluoroethylene reactor with a volume of 25ml and seal at a reaction temperature of 95°C for 2 hours. After the reaction, when the temperature of the reaction kettle drops to room temperature, take out the liquid in the kettle and wash it several times with deionized water, pour the precipitate into a clean porcelain cup, dry it at 65°C, grind and collect it, and then get light green Powdered copper hydroxychlor...

Embodiment 2

[0034] Embodiment 2 prepares Cu 2 (OH) 3 The whole process of Cl nanosheets.

[0035] Copper nitrate (Cu(NO 3 ) 2 ), hexamethylenetetramine (HMT) and sodium chloride (NaCl) as raw materials, first take 0.210g hexamethylenetetramine (HMT) and 0.362g copper nitrate (Cu(NO 3 ) 2 ) into a clean beaker, add 15ml of deionized water and stir in a magnetic stirrer for 15min, add 0.438g of sodium chloride (NaCl) and continue stirring for 10min after the stirring is completed, so that the medicine can fully react, and pour the reacted liquid into Heat in a polytetrafluoroethylene reactor with a volume of 25ml and seal at a reaction temperature of 95°C for 4 hours. After the reaction, when the temperature of the reaction kettle drops to room temperature, take out the liquid in the kettle and wash it several times with deionized water, pour the precipitate into a clean porcelain cup, dry it at 65°C, grind and collect it, and then get light green Powdered copper hydroxychloride sampl...

Embodiment 3

[0037] Embodiment 3 prepares Cu 2 (OH) 3 The whole process of Cl nanosheets.

[0038] Copper nitrate (Cu(NO 3 ) 2 ), hexamethylenetetramine (HMT) and sodium chloride (NaCl) as raw materials, first take 0.210g hexamethylenetetramine (HMT) and 0.362g copper nitrate (Cu(NO 3 ) 2 ) into a clean beaker, add 15ml of deionized water and stir in a magnetic stirrer for 15min, add 0.438g of sodium chloride (NaCl) and continue stirring for 10min after the stirring is completed, so that the medicine can fully react, and pour the reacted liquid into Heat in a sealed polytetrafluoroethylene reactor with a volume of 25 ml at a reaction temperature of 95° C. for 6 hours. After the reaction, when the temperature of the reaction kettle drops to room temperature, take out the liquid in the kettle and wash it several times with deionized water, pour the precipitate into a clean porcelain cup, dry it at 65°C, grind and collect it, and then get light green Powdered copper hydroxychloride samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com