Industrial sewage treatment method

A treatment method and technology for industrial sewage, applied in water/sewage treatment, flotation water/sewage treatment, light water/sewage treatment, etc., can solve the problem of inability to treat industrial sewage with heavy metal content, expensive operation cost, long standing time, etc. problems, to achieve the effect of improving coagulation efficiency, accelerating sedimentation rate and reducing pollution degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

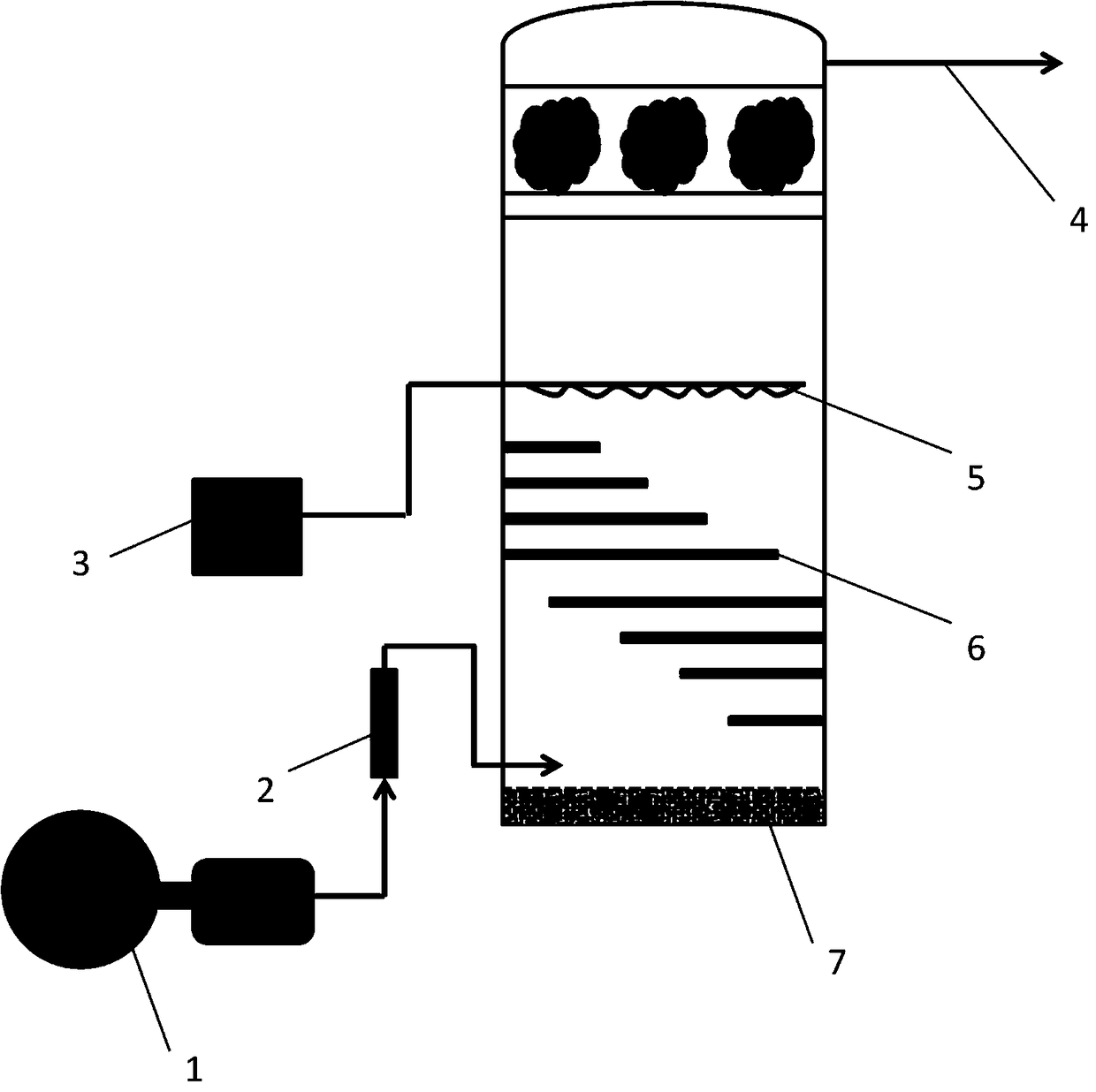

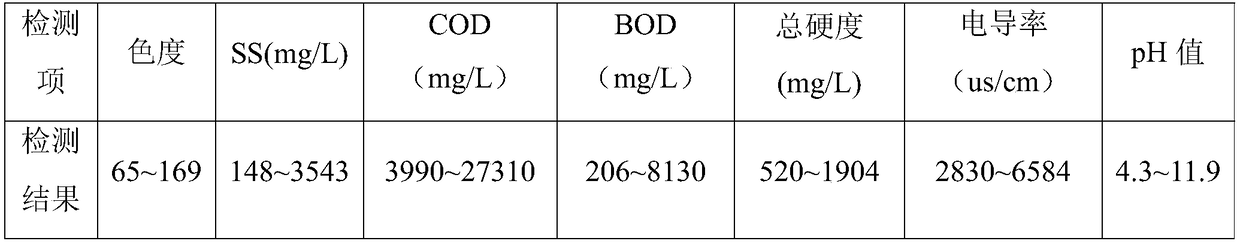

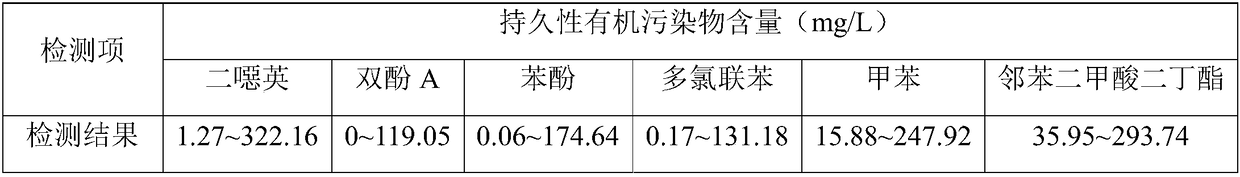

[0039]A kind of industrial sewage treatment method, its steps are as follows:

[0040] (1) Mechanical treatment: filter industrial sewage through mechanical grille, and the filtered effluent enters the oil-water separator to remove sundries, oil slicks and suspended solids;

[0041] (2) softening treatment: the effluent of the oil-water separator is passed into the chemical reactor, adding soda ash, stirring and mixing, making the pH value 8, removing hardness ions such as calcium and magnesium to soften the water body, and simultaneously reacting to generate suspended floc particles;

[0042] (3) Enhanced coagulation: the effluent after softening treatment is passed into the coagulation air flotation machine, and cationic flocculant is added at 0.1kg per ton of water to drive away grease, colloid, suspended solids and suspended floc particles generated in step (2) , reduce the BOD and COD content in sewage;

[0043] (4) Pulse discharge plasma-photocatalytic synergistic degra...

Embodiment 2

[0055] A kind of industrial sewage treatment method, its steps are as follows:

[0056] (1) Mechanical treatment: filter industrial sewage through mechanical grille, and the filtered effluent enters the oil-water separator to remove sundries, oil slicks and suspended solids;

[0057] (2) softening treatment: the effluent of the oil-water separator is passed into the chemical reactor, adding soda ash, stirring and mixing, making the pH value 9, removing hardness ions such as calcium and magnesium to soften the water body, and simultaneously reacting to generate suspended floc particles;

[0058] (3) Enhanced coagulation: the effluent after softening treatment is passed into the coagulation air flotation machine, and cationic flocculant is added at 0.2kg per ton of water to drive away grease, colloid, suspended solids and suspended floc particles generated in step (2) , reduce the BOD and COD content in sewage;

[0059] (4) Pulse discharge plasma-photocatalytic synergistic degr...

Embodiment 3

[0071] A kind of industrial sewage treatment method, its steps are as follows:

[0072] (1) Mechanical treatment: filter industrial sewage through mechanical grille, and the filtered effluent enters the oil-water separator to remove sundries, oil slicks and suspended solids;

[0073] (2) Softening treatment: the effluent of the oil-water separator is passed into the chemical reactor, adding soda ash, stirring and mixing, so that the pH range is 11, removing hardness ions such as calcium and magnesium to soften the water body, and simultaneously reacting to form suspended floc particles;

[0074] (3) Enhanced coagulation: the effluent after softening treatment is passed into the coagulation air flotation machine, and cationic flocculant is added at 0.3kg per ton of water to drive away grease, colloid, suspended solids and suspended floc particles generated in step (2) , reduce the BOD and COD content in sewage;

[0075] (4) Pulse discharge plasma-photocatalytic synergistic deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com