Adsorption composite material used for water quality detection, and preparation method thereof

A composite material, water quality detection technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc. Avoid adverse effects, the effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

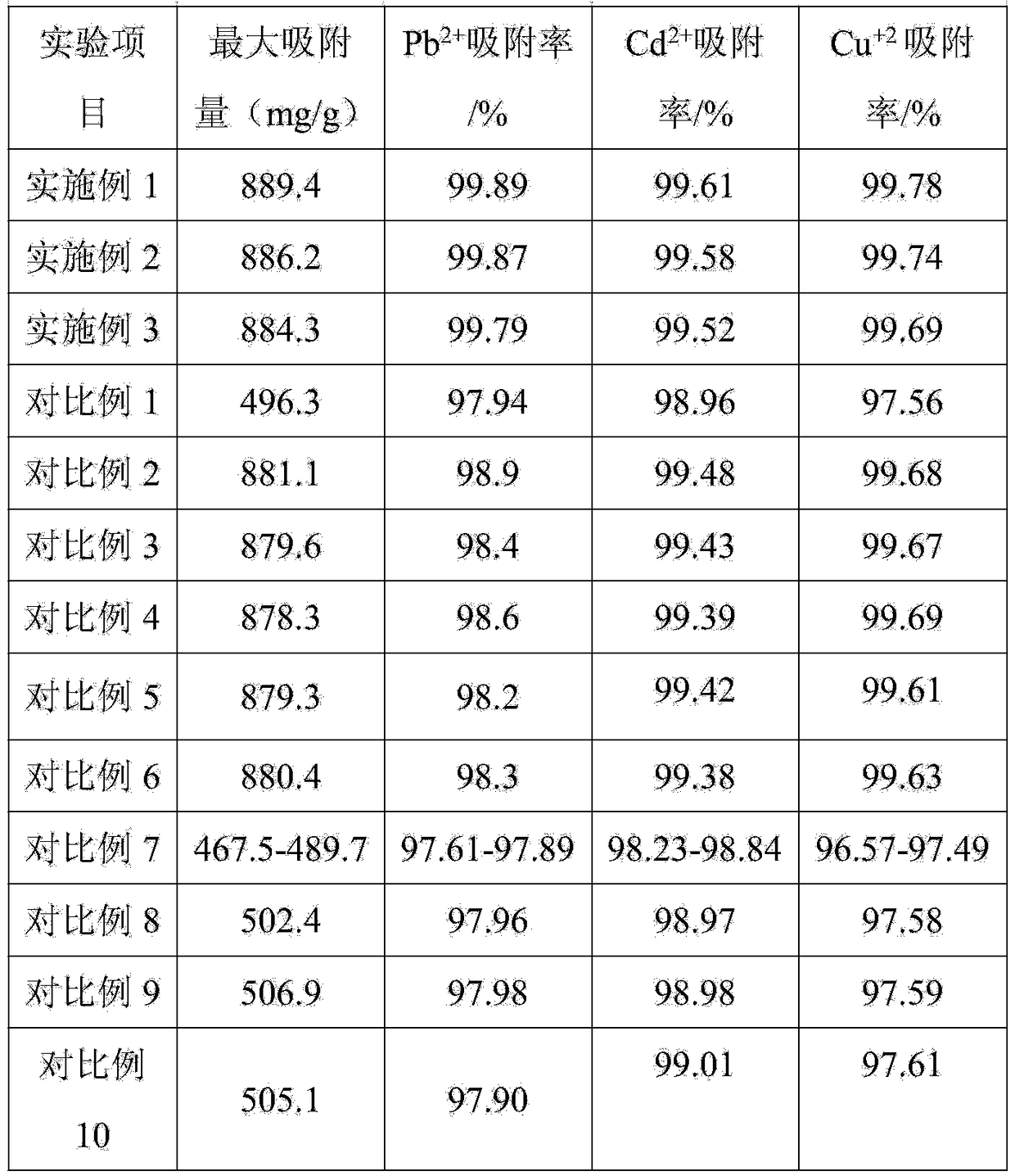

Examples

preparation example Construction

[0034] The present invention also provides a kind of preparation method of the adsorption composite material that is used for water quality detection, comprises the steps:

[0035] S1. Mix nanoscale ceramic powder, sodium carbonate, propylene glycol and sodium polyacrylate evenly, heat up to 80-90°C, keep warm for 10-20min, then stir at 650-850r / min for 20-30min, then add ferrous sulfate, Sodium citrate, anhydrous sodium sulfate, disodium edetate, sodium sulfite, polyethylene glycol, potassium iodide, ammonium citrate, dimethylglyoxime, potassium dihydrogen phosphate, sodium tetraborate, and dodecylbenzenesulfuric acid Mix the sodium evenly, stir at 1500-2500r / min for 1-2h, cool to room temperature to obtain the base material;

[0036] S2. Grind the modified adsorbent and modified filler into powder, then add polyhydroxyalkanoate and mix evenly, heat up to 110-130°C, keep warm for 10-30min, then chitosan and silane coupling agent KH-570 Mix evenly, stir at 1200-1400r / min for ...

Embodiment 1

[0039] An adsorption composite material used for water quality detection, in parts by weight, comprising the following raw materials: 42.6 parts of modified adsorbent, 28.9 parts of modified filler, 7.4 parts of chitosan, 13.2 parts of polyhydroxyalkanoate, silane Joint agent KH-570 2.6 parts, 4.3 parts of ferrous sulfate, 2.9 parts of sodium polyacrylate, 4.2 parts of sodium citrate, 3.1 parts of anhydrous sodium sulfate, 1.9 parts of disodium edetate, 2.2 parts of sodium sulfite, polyethylene glycol 4.1 parts, 6.3 parts of potassium iodide, 4.2 parts of nano-scale ceramic powder, 3.4 parts of ammonium citrate, 4.3 parts of sodium carbonate, 9.8 parts of propylene glycol, 3.3 parts of dimethylglyoxime, 3.4 parts of potassium dihydrogen phosphate, 5.8 parts of sodium tetraborate, ten 4.4 parts of sodium dialkylbenzene sulfate.

[0040] The modified adsorbent was prepared according to the following process: 18 parts by weight of attapulgite, 7.2 parts of bentonite and 6.3 parts...

Embodiment 2

[0047] An adsorption composite material used for water quality detection, in parts by weight, comprising the following raw materials: 30 parts of modified adsorbent, 35 parts of modified filler, 6 parts of chitosan, 14 parts of polyhydroxyalkanoate, silane di Joint agent KH-5701, 6 parts of ferrous sulfate, 2 parts of sodium polyacrylate, 6 parts of sodium citrate, 3 parts of anhydrous sodium sulfate, 2.5 parts of disodium edetate, 1 part of sodium sulfite, polyethylene glycol 5 parts, 5 parts of potassium iodide, 6 parts of nano ceramic powder, 2 parts of ammonium citrate, 6 parts of sodium carbonate, 5 parts of propylene glycol, 5 parts of dimethylglyoxime, 1 part of potassium dihydrogen phosphate, 8 parts of sodium tetraborate, ten parts 3 parts of sodium dialkylbenzene sulfate.

[0048] The modified adsorbent was prepared according to the following process: 12 parts of attapulgite, 8 parts of bentonite and 4 parts of kaolin were evenly mixed in parts by weight, dried at 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com