A kind of preparation method of the small size nano-silver used in water-based conductive ink

A conductive ink, small size technology, applied in the field of small size nano silver preparation, can solve the problems of safety hazards, environmental pollution, etc., achieve the effect of inhibiting agglomeration, process environment friendly, and less content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

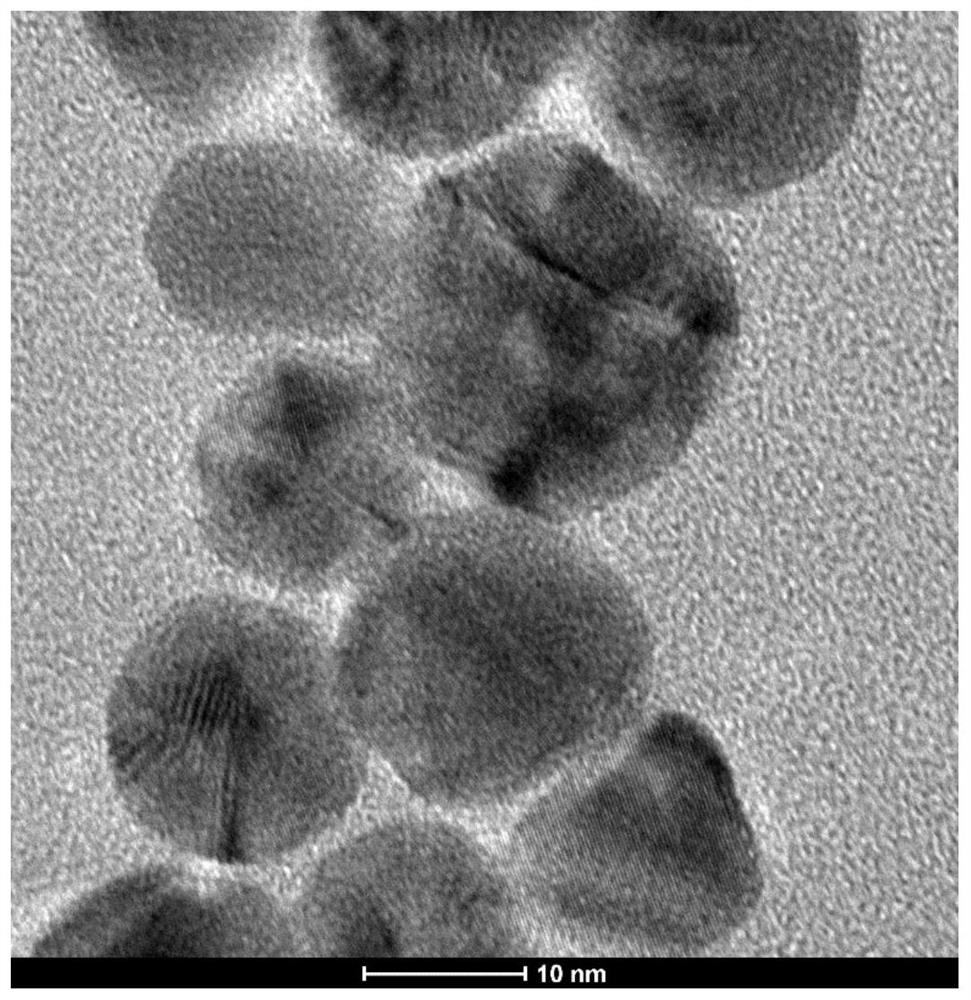

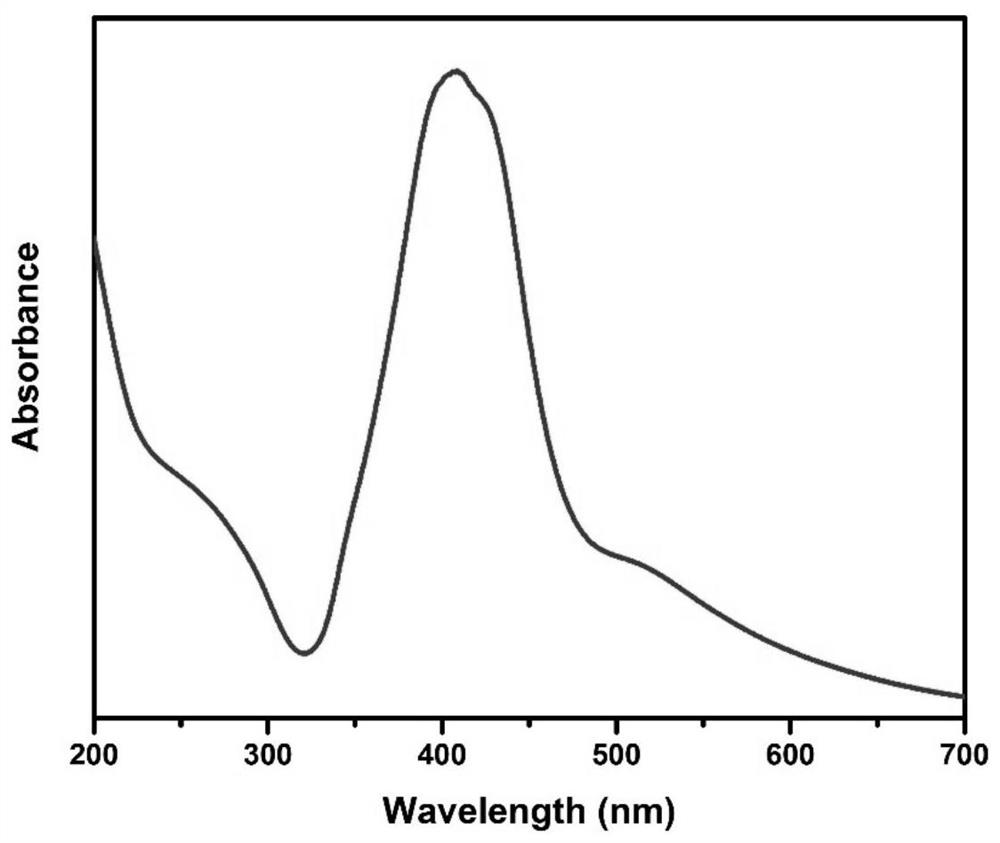

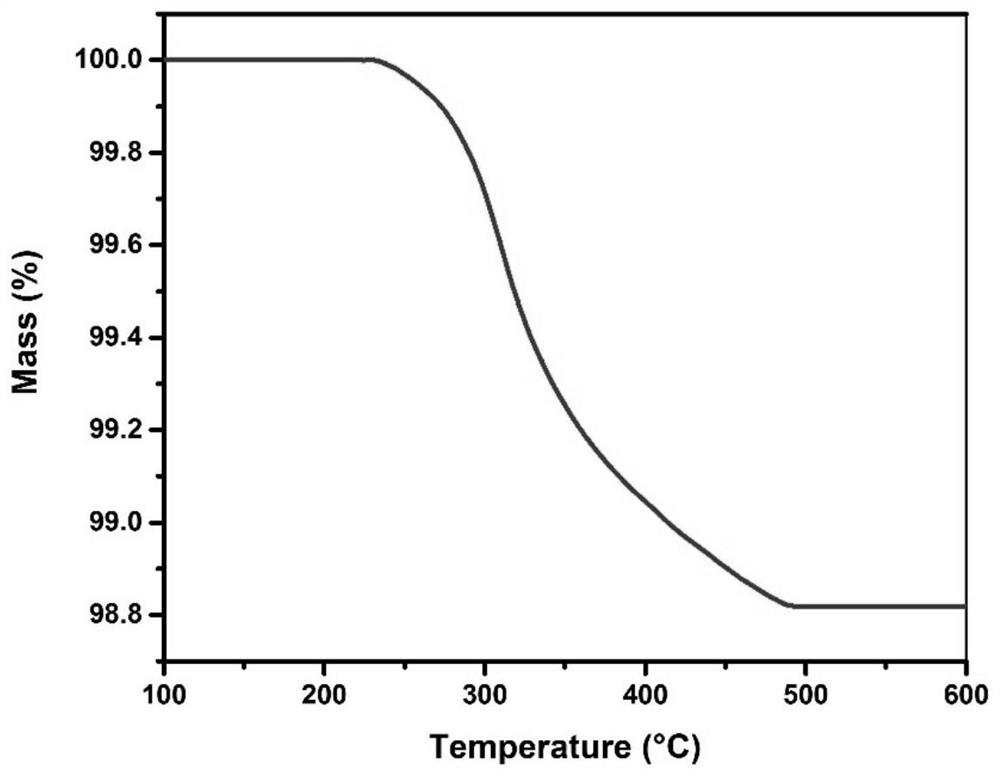

Image

Examples

preparation example Construction

[0024] A kind of preparation method of the small size nano silver that is used for water-based conductive ink, comprises the following steps:

[0025] Step 1, adding nucleation promoting stabilizer A, water-soluble organic protective agent B and reducing agent into deionized water in sequence, stirring and mixing uniformly to obtain mixed solution A; wherein, the nucleation promoting stabilizer A in mixed solution A The concentration is 0.1-0.6mol / L, the concentration of the water-soluble organic protective agent B is 0.5-1.0mol / L, the concentration of the reducing agent is 5-10mol / L, and the stirring speed is 400-800rpm;

[0026] Step 2, preparing a water-soluble silver salt solution with a concentration of 5-12 mol / L, and adding it into the mixed solution A obtained in step 1 at a rate of 15-25 drops / min, stirring and mixing evenly to obtain a mixed solution B; wherein, mixing The molar ratio of the silver salt in the liquid B to the reducing agent in step 1 is 1: (3~7);

...

Embodiment 1

[0034]Add 4.3g of trisodium citrate, 3g of polyacrylic acid, and 25g of ethanolamine into 50mL of deionized water in sequence, and magnetically stir at a speed of 600rpm at room temperature for 30min to obtain a mixed solution A; Add 10 mL of 10 mol / L silver nitrate solution dropwise, stir magnetically for 10 minutes to obtain mixed solution B; react the obtained mixed solution B in a water bath at 30°C for 30 minutes, then raise the temperature to 45°C at a rate of 1.0°C / min, and react in a water bath for 10 minutes , then raised the temperature to 65°C at a heating rate of 1.0°C / min, reacted in a water bath for 30 minutes, and obtained a gray-green solution; added 250ml of absolute ethanol to the reacted solution system, kept magnetic stirring during the addition process, and then stood still, The nano-metallic silver particles in the solution all settle after standing, and the precipitated solids are collected; the collected precipitated solids are washed in a mixed solution...

Embodiment 2

[0040] Add 3.2g of chitosan, 5.8g of polyglutamic acid, and 30g of diethanolamine into 50mL of deionized water in turn, and magnetically stir at a speed of 600rpm at room temperature for 25min to obtain mixed solution A; Add 10mL of 8mol / L silver nitrate solution dropwise to solution A, and stir magnetically for 10min to obtain mixed solution B; the obtained mixed solution B was reacted in a water bath at 30°C for 20min, and then heated to 40°C at a heating rate of 1.0°C / min , react in a water bath for 10 minutes, then raise the temperature to 70°C at a heating rate of 1.0°C / min, and react in a water bath for 40 minutes to obtain a gray-green solution; add 400ml of absolute ethanol to the reacted solution system, and maintain magnetic stirring during the addition process. Then stand still, the nano-metallic silver particles in the solution all settle after standing, and collect the precipitated solid; the precipitated solid collected is washed in a mixed solution of deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com