Magnesium alloy material with heparin loaded at surface as well as preparation method and application thereof

A technology of magnesium alloy and heparin, which is applied in medical formula, surgery, coating, etc., can solve the problems of poor biocompatibility of magnesium alloy, limit the clinical application of magnesium alloy, and increase the alkalinity of surrounding tissues, so as to improve corrosion resistance, Excellent anticoagulant performance and selective endothelial cell growth-promoting function, and the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

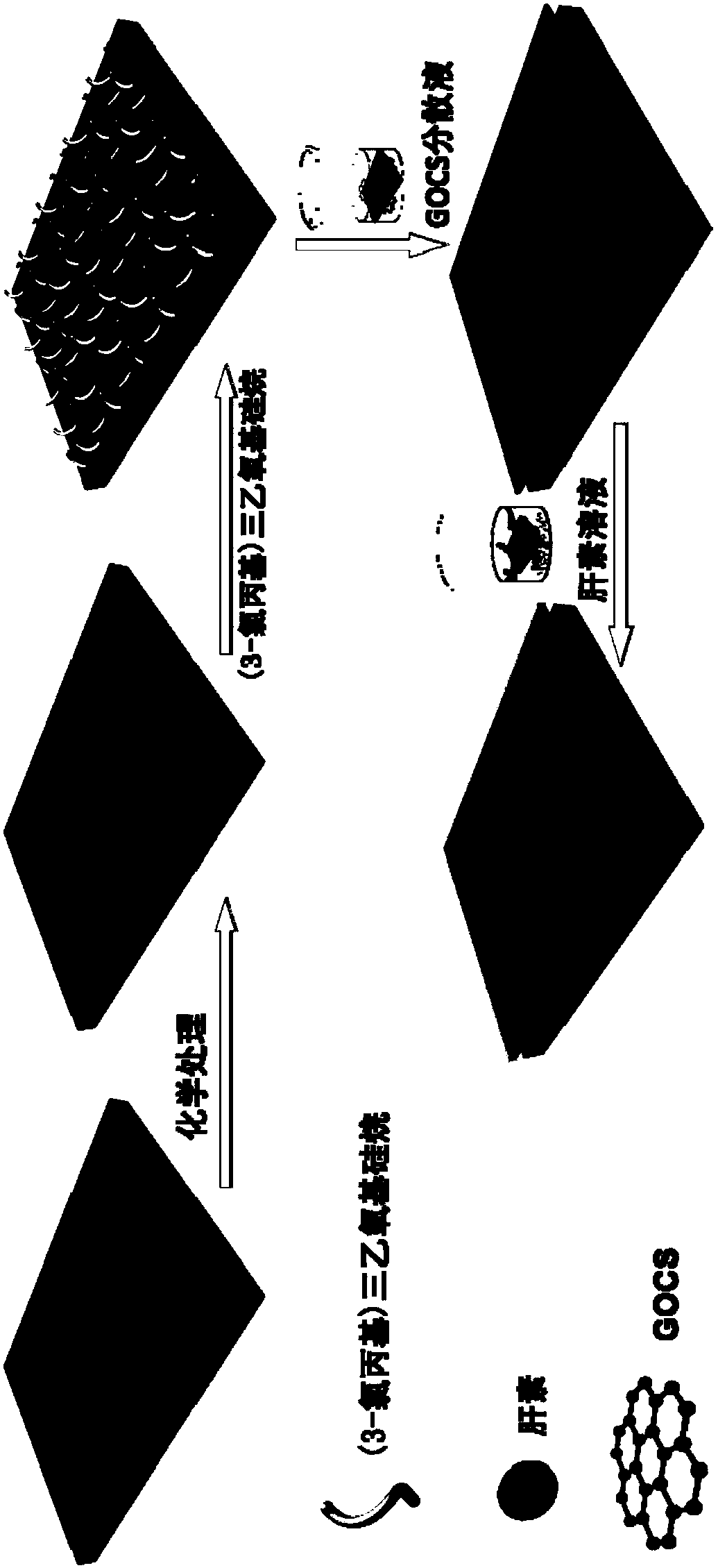

[0032] Example 1 Preparation of magnesium alloy material with heparin on its surface

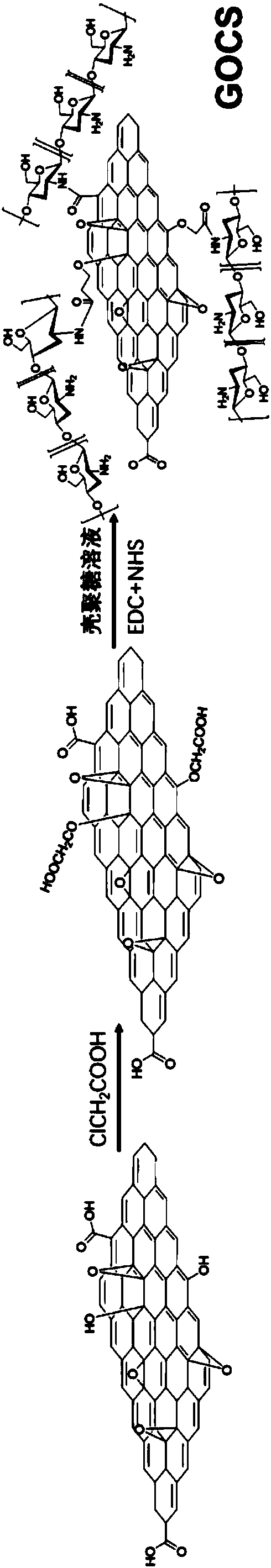

[0033] 1. Modification of carboxylated graphene oxide with chitosan to obtain GOCS:

[0034] 1) Ultrasonic disperse graphene oxide in 0.01mol / L sodium hydroxide solution to obtain a 5mg / ml graphene oxide solution, add 0.01mol chloroacetic acid, stir and react for 2-4 hours, and repeatedly centrifuge and wash the solution to neutral To remove impurities to obtain carboxylated graphene oxide (GO-COOH); GO-COOH is dissolved in water to obtain a GO-COOH solution, and the prepared GO-COOH solution has a concentration of 1 mg / ml;

[0035]2) Ultrasonic disperse 1 mg / ml GO-COOH solution and chitosan (CS, 5 mg / ml) in MES buffer solution (2-morpholineethanesulfonic acid buffer, adjust the pH of the solution to about 6), add 1 -(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC, 10mM) and N-hydroxysuccinimide (NHS, 10mM) solution, shaking reaction for 2-4 hours, the solution The unreacted substances we...

Embodiment 2

[0043] Example 2 Preparation of magnesium alloy material with heparin on its surface

[0044] 1. Modification of carboxylated graphene oxide with chitosan to obtain GOCS solution:

[0045] 1) Ultrasonic disperse graphene oxide in 0.1mol / L sodium hydroxide solution to obtain a 5mg / ml graphene oxide solution, add 0.03mol chloroacetic acid, stir and react for 2-4 hours, and repeatedly centrifuge and wash the solution to neutral To remove impurities to obtain carboxylated graphene oxide (GO-COOH); GO-COOH is dissolved in water to obtain a GO-COOH solution; the prepared GO-COOH solution has a concentration of 5 mg / ml;

[0046] 2) Ultrasonic disperse 5 mg / ml GO-COOH solution and chitosan (CS, 10 mg / ml) in MES buffer solution (adjust the pH of the solution to about 6), add 1-(3-dimethylaminopropyl )-3-ethylcarbodiimide (EDC, 10mM) and N-hydroxysuccinimide (NHS, 10mM) solution, shaking reaction for 2-4 hours, the solution was repeatedly centrifuged and washed to remove unreacted subs...

Embodiment 3

[0054] Example 3 Preparation of magnesium alloy material with heparin on its surface

[0055] 1. Modification of carboxylated graphene oxide with chitosan to obtain GOCS:

[0056] 1) Ultrasonic disperse graphene oxide in 0.05mol / L sodium hydroxide solution to obtain 5mg / ml graphene oxide solution, add 0.05mol chloroacetic acid, stir and react for 2-4 hours, and repeatedly centrifuge and wash the solution to neutral To remove impurities to obtain carboxylated graphene oxide (GO-COOH), GO-COOH is dissolved in water to obtain GO-COOH solution; the concentration of the prepared GO-COOH solution is 3mg / ml;

[0057] 2) Ultrasonic disperse 3mg / ml GO-COOH solution and chitosan (CS, 7.5mg / ml) in MES buffer solution (adjust the pH of the solution to about 6), add 1-(3-dimethylaminopropyl Base)-3-ethylcarbodiimide (EDC, 10mM) and N-hydroxysuccinimide (NHS, 10mM) solution, shaking reaction for 2-4 hours, the solution was repeatedly centrifuged and washed to remove unreacted substances, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com