Preparation method of composite heat-dissipating powder coating for high-temperature component

A technology for powder coatings and high-temperature components, which is applied in the field of preparation of composite heat-dissipating powder coatings for high-temperature components, can solve problems such as difficult large-scale, large-scale preparation and production, poor mechanical properties of heat-dissipating coatings, and poor thermal conductivity, etc., to achieve Excellent high-temperature thermal stability and electrical insulation, safe and convenient transportation, and high raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

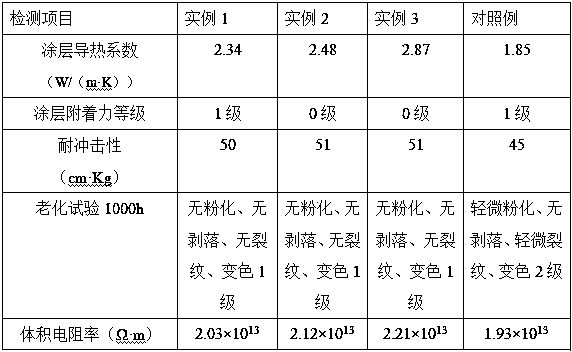

Examples

example 1

[0023] Add 60g of boric acid into 500mL of deionized water, stir at 300r / min for 20min at 50°C, then add 80g of urea, heat to 60°C, stir for 30min, transfer to a rotary evaporator, evaporate to dryness at 50°C, To obtain the precursor, place the precursor in a muffle furnace, heat it to 800°C for 5 hours in a nitrogen atmosphere, and calcine it for 5 hours. After cooling to room temperature, wash the calcined product twice with 1% hydrochloric acid, and then wash it with absolute ethanol After 2 times, transfer it to a drying oven and dry at 50°C for 10 hours to obtain flake boron nitride. Take 30g of SEBS thermoplastic elastomer, add it to 100g of white oil, and stir at 200r / min for 20min to obtain a mixed solution. Press the Mix with cyclohexane at a mass ratio of 1:5, stir evenly to obtain an adhesive solution, take polystyrene and put it into a pulverizer and grind it to a particle size of 20 μm to obtain polystyrene particles, take 20g of adhesive solution and 120g of poly...

example 2

[0025]Add 70g of boric acid into 600mL of deionized water, stir at 350r / min for 25min at 55°C, then add 100g of urea, heat to 62°C, stir for 35min, transfer to a rotary evaporator, evaporate to dryness at 60°C, To obtain the precursor, place the precursor in a muffle furnace, heat it to 900°C and calcinate it for 5 hours under a nitrogen atmosphere, after cooling to room temperature, wash the calcined product twice with 1% hydrochloric acid, and then wash it with absolute ethanol After 2 times, transfer it to a drying oven and dry at 55°C for 11 hours to obtain flaky boron nitride. Take 40g of SEBS thermoplastic elastomer, add it to 120g of white oil, and stir at 250r / min for 25min to obtain a mixed solution. Press the Mix with cyclohexane at a mass ratio of 1:5, stir evenly to obtain an adhesive solution, take polystyrene and put it into a pulverizer and grind it to a particle size of 30 μm to obtain polystyrene particles, take 25g of adhesive solution and 160g of polystyrene ...

example 3

[0027] Add 80g of boric acid into 800mL deionized water, stir at 400r / min for 30min at 60°C, then add 120g of urea, heat to 65°C, stir for 40min, transfer to a rotary evaporator, evaporate to dryness at 70°C, To obtain the precursor, place the precursor in a muffle furnace, heat it to 1000°C and calcinate it for 6 hours under nitrogen atmosphere, after cooling to room temperature, wash the calcined product with 1% hydrochloric acid for 3 times, and then wash it with absolute ethanol After 3 times, transfer it to a drying oven and dry at 60°C for 12 hours to obtain flaky boron nitride. Take 50g of SEBS thermoplastic elastomer, add it to 150g of white oil, and stir at 300r / min for 30min to obtain a mixed solution. Press the Mix with cyclohexane at a mass ratio of 1:5, stir evenly to obtain an adhesive solution, take polystyrene and put it into a pulverizer and grind it to a particle size of 40 μm to obtain polystyrene particles, take 30g of adhesive solution and 180g of polystyre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com