Process for preparing magnesium hydroxide and sodium sulfite by using magnesium sulfite

A technology of magnesium sulfite and sodium sulfite, applied in the field of chemical technology, can solve the problems of consumption of caustic soda or soda ash, destruction, and high production cost, and achieve the effect of strengthening value-added benefits, reducing environmental pollution, and realizing circular economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention are given in the following drawings, and the embodiments described with reference to the drawings are exemplary, and are only used for explaining the present invention, and should not be construed as limiting the present invention.

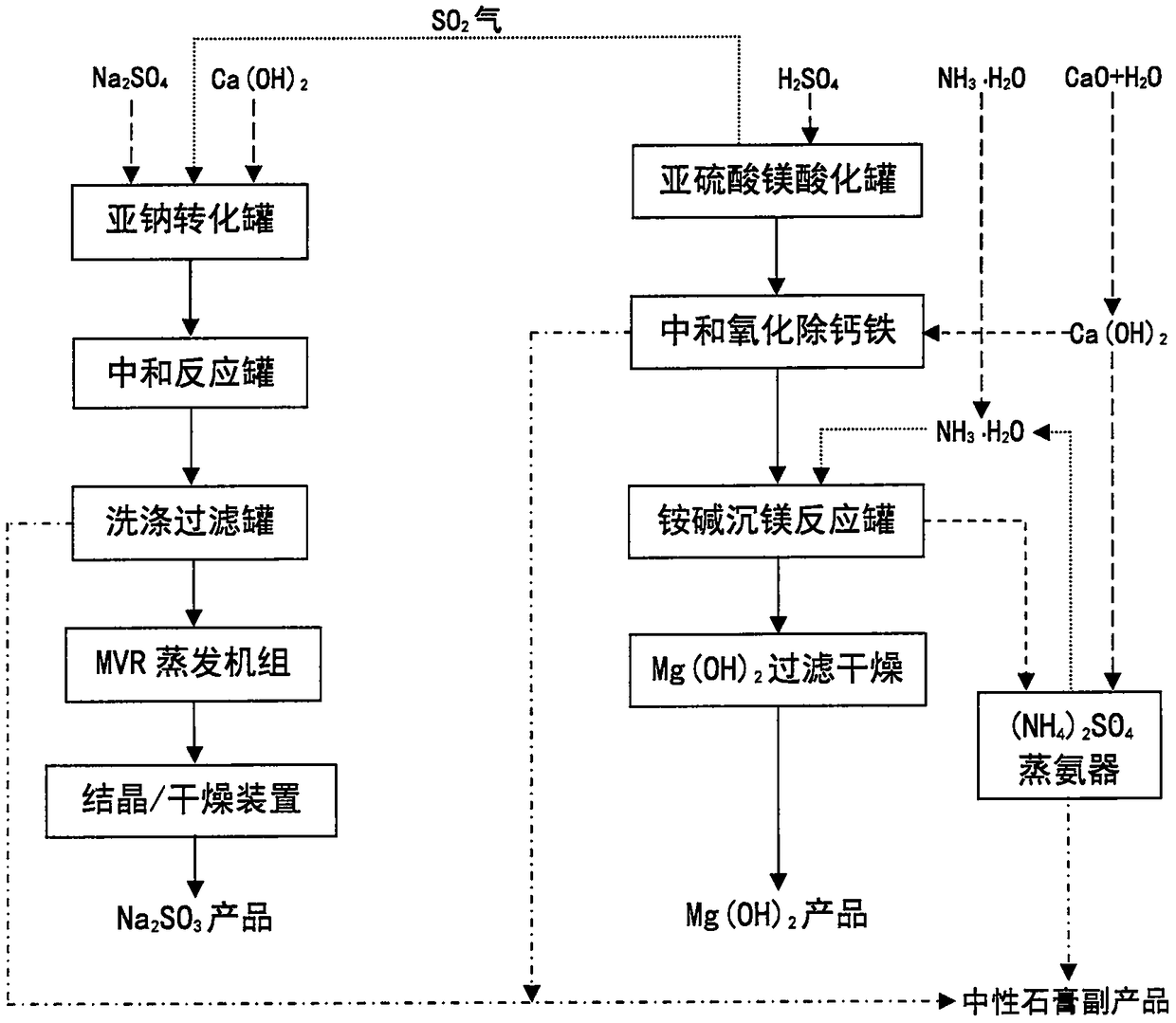

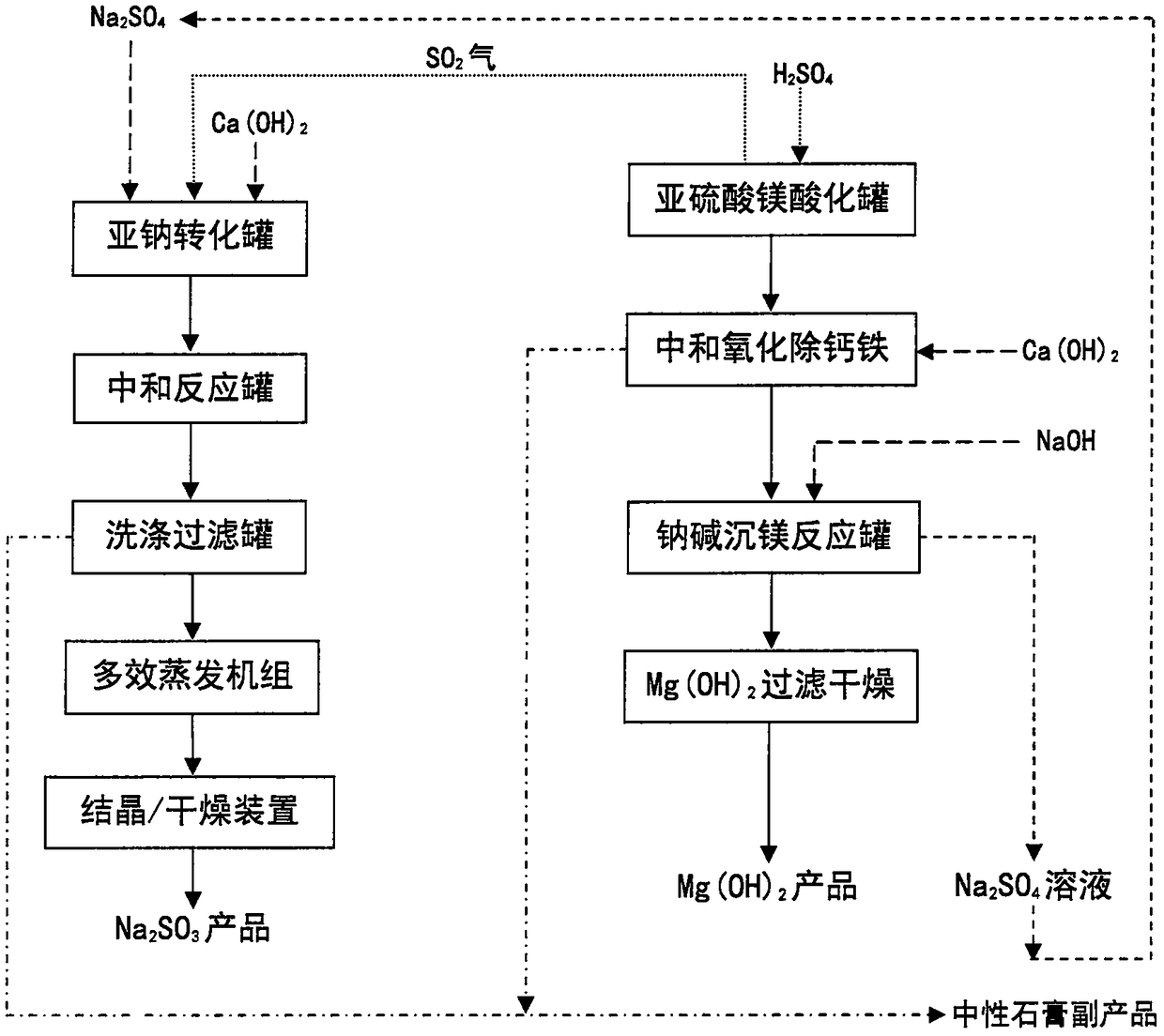

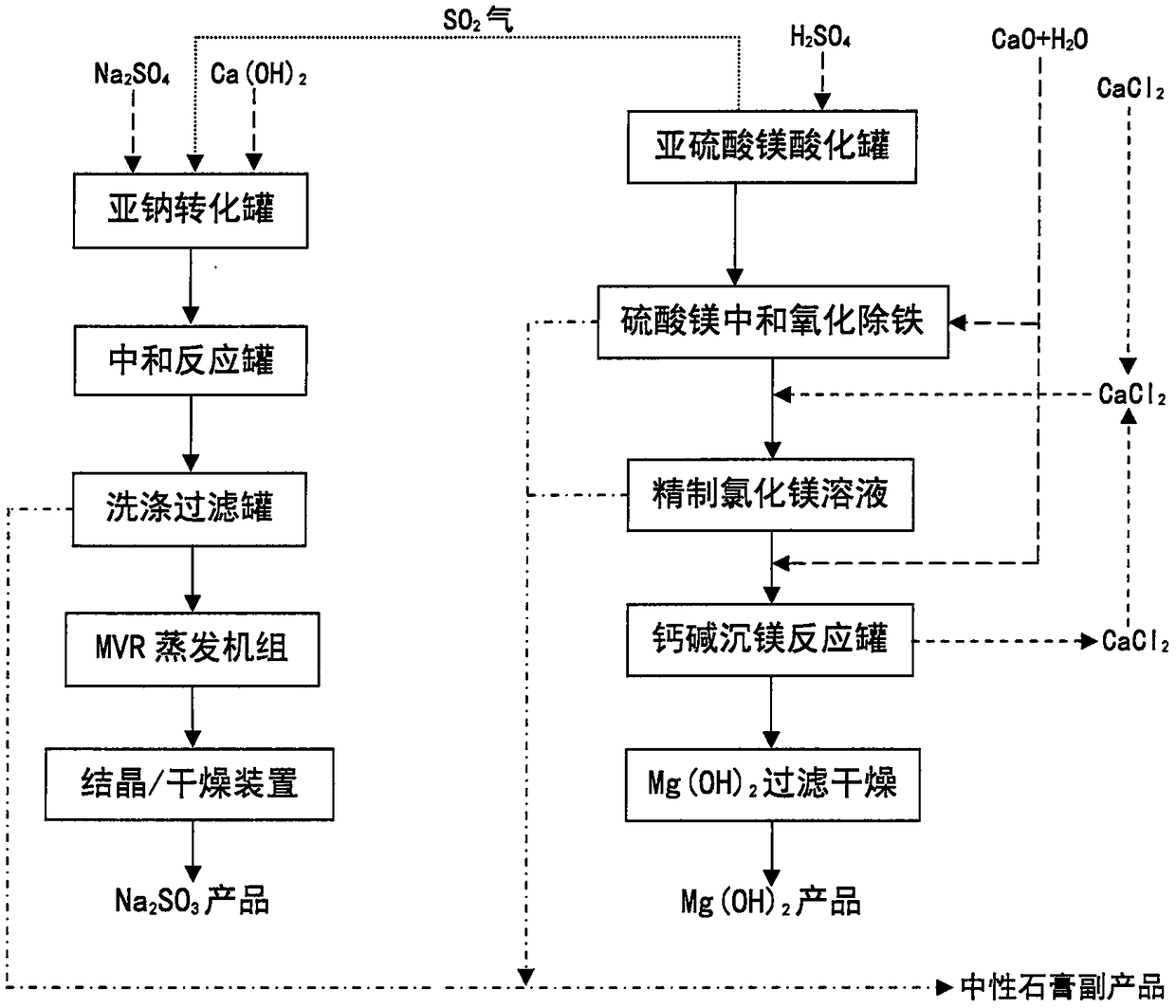

[0048] figure 1 Provided is magnesium sulfite to produce magnesium hydroxide, sodium sulfite and the flow chart of byproduct gypsum process, and specific examples are as follows figure 1 Shown: First, crush magnesium sulfite, stir in a stirring reactor to prepare a suspension of magnesium sulfite with a concentration of 25%, slowly add sulfuric acid with a concentration of 60% for acidification, and control the reaction conditions so that magnesium sulfite slowly dissolves and releases SO 2 (Sent to the process of preparing sodium sulfite), control the reaction temperature at 70-80°C, stir the reaction for 3.0h until the magnesium sulfite is completely dissolved, then stop adding acid; heat the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com