Low voc type regenerated polyester fiber and preparation method thereof

A technology of recycled polyester and fiber, applied in the chemical characteristics of fibers, rayon manufacturing, fire-retardant and flame-retardant filament manufacturing, etc., can solve the problems of affecting product performance, poor dispersion, high energy consumption, etc. Good hue, low VOCs content, and the effect of accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

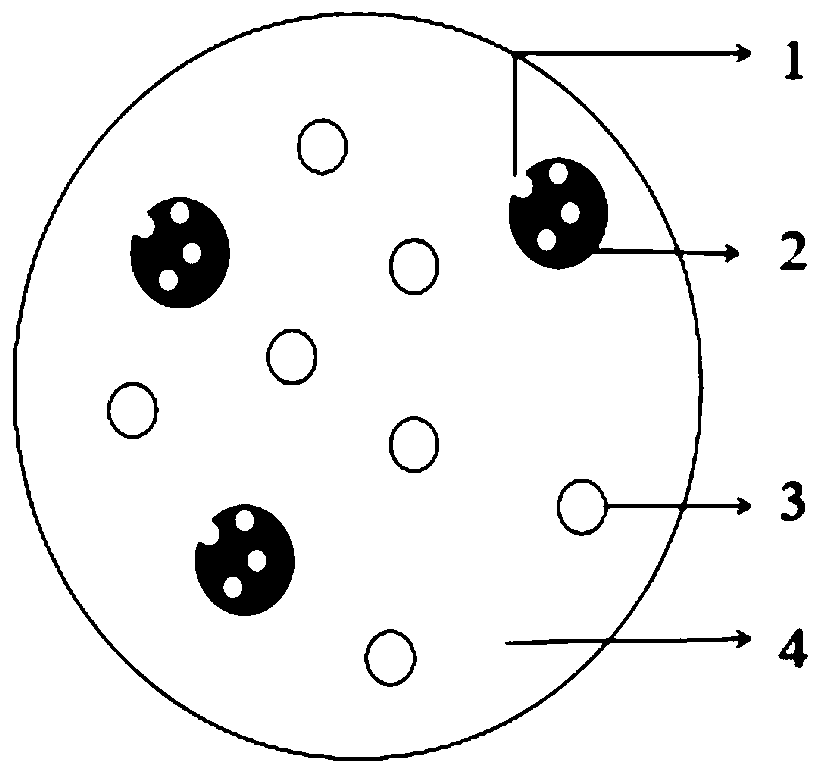

Image

Examples

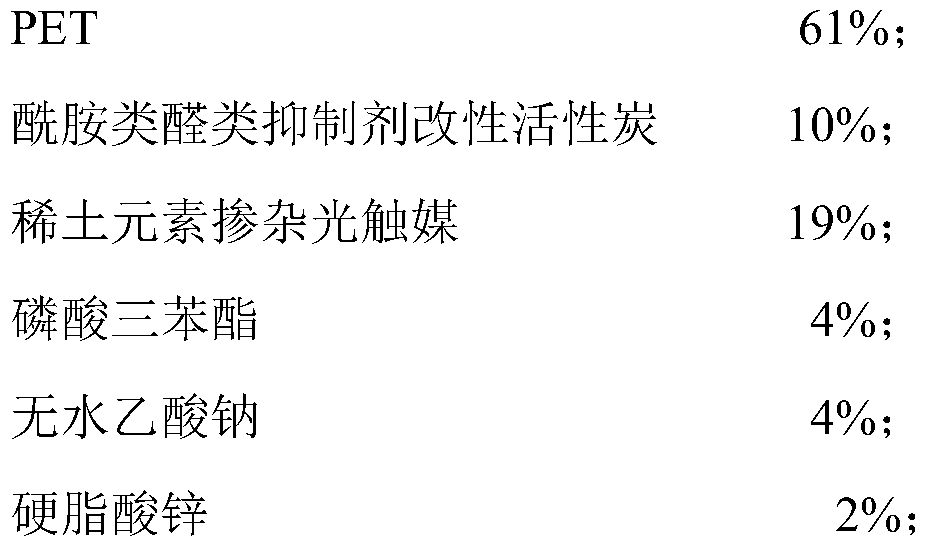

Embodiment 1

[0057] A method for preparing low-VOC type regenerated polyester fiber, the specific steps are as follows:

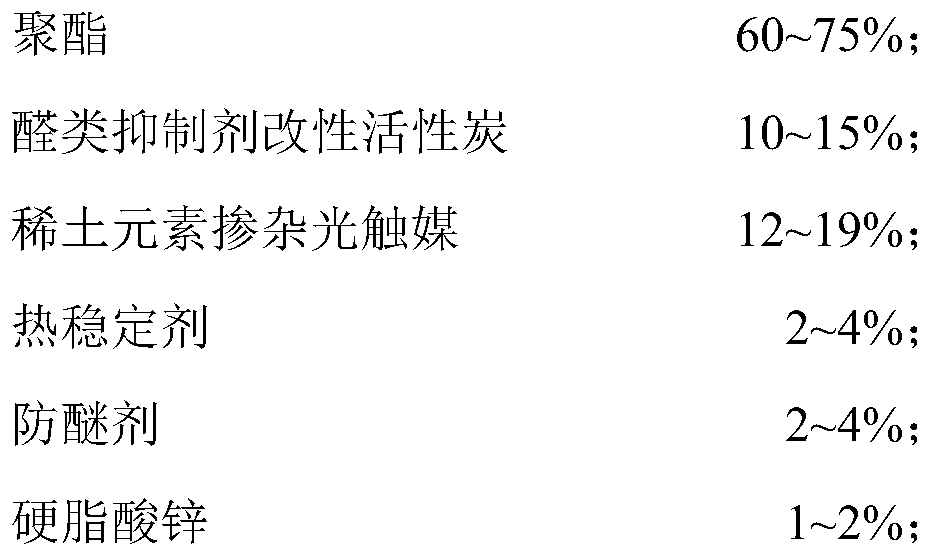

[0058] A. Preparation of VOCs-removing masterbatch:

[0059] (1) prepare amide aldehyde inhibitor modified activated carbon;

[0060] (1.1) Activation of activated carbon: mix the activated carbon raw material with KOH solution with a concentration of 0.3mol / L at a mass ratio of 2.2:1, and under the protection of nitrogen, raise the temperature to 820°C at a rate of 13K / min, and activate for 2.2h ;

[0061] (1.2) Post-treatment: crush the activated carbon and sieve it into 20 meshes, wash it with ultrapure water until the pH of its aqueous solution is stable, and dry it in vacuum at 112°C for 14 hours;

[0062] (1.3) Modification: Mix polycaprolactam, post-treated activated carbon, and ethanol at a mass ratio of 2:1:2, and ultrasonically treat for 4 hours to obtain amide-type aldehyde inhibitor-modified activated carbon, wherein the prepared amides The content of pol...

Embodiment 2

[0079] A method for preparing low-VOC type regenerated polyester fiber, the specific steps are as follows:

[0080] A. Preparation of VOCs-removing masterbatch:

[0081] (1) prepare amide aldehyde inhibitor modified activated carbon;

[0082] (1.1) Activation of activated carbon: mix the activated carbon raw material with the KOH solution with a concentration of 0.1mol / L at a mass ratio of 2.5:1, and under the protection of nitrogen, raise the temperature to 850°C at a rate of 18K / min, and activate for 2.6h ;

[0083] (1.2) Post-treatment: crush the activated carbon and sieve it into 24 meshes, wash it with ultrapure water until the pH of its aqueous solution is stable, and dry it in vacuum at 118°C for 18 hours;

[0084] (1.3) Modification: Mix anthranilamide, post-treated activated carbon, and ethanol in a mass ratio of 2:1.5:2, and ultrasonically treat for 5 hours to obtain amide-type aldehyde inhibitor-modified activated carbon, wherein the prepared amide The content of...

Embodiment 3

[0100] A method for preparing low-VOC type regenerated polyester fiber, the specific steps are as follows:

[0101] A. Preparation of VOCs-removing masterbatch:

[0102] (1) prepare amide aldehyde inhibitor modified activated carbon;

[0103] (1.1) Activation of activated carbon: mix the activated carbon raw material and KOH solution with a concentration of 0.5mol / L at a mass ratio of 2.8:1, and under the protection of nitrogen, raise the temperature to 870°C at a rate of 15K / min, and activate for 3h;

[0104] (1.2) Post-treatment: crush the activated carbon and sieve it into 25 meshes, wash it with ultrapure water until the pH of its aqueous solution is stable, and dry it in vacuum at 105°C for 20 hours;

[0105] (1.3) Modification: Mix stearylamide, post-treated activated carbon and ethanol in a mass ratio of 2:1.8:2, and ultrasonically treat for 4 hours to obtain amide-type aldehyde inhibitor-modified activated carbon, wherein the prepared amide-type aldehyde The content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com