Preparation method of tricobalt tetraoxide-ferric oxide composite oxide

A technology of ferric oxide and composite oxides, applied in the direction of cobalt oxide/cobalt hydroxide, iron oxide/iron hydroxide, iron oxide, etc., which can solve the problem of low theoretical specific capacity and density, large loss of irreversible capacity, and unsatisfactory The high energy density and portability requirements of lithium-ion batteries and other issues, to achieve the effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of tricobalt tetroxide-ferric oxide composite oxide, comprising the steps of:

[0024] S1. Co-dissolve cobalt dichloride, ferric nitrate, 1,3,5-benzenetricarboxylic acid, and hydrofluoric acid in water, stir, put them into a polytetrafluoroethylene lining, then put them into a reaction kettle, and heat up. Insulation, obtain cobalt / iron coordination polymer;

[0025] S2. Calcining the cobalt / iron coordination polymer and cooling to obtain tricobalt tetroxide-ferric oxide composite oxide.

Embodiment 2

[0027] A preparation method of tricobalt tetroxide-ferric oxide composite oxide, comprising the steps of:

[0028] S1. Co-dissolve cobalt dichloride, ferric nitrate, 1,3,5-benzenetricarboxylic acid, and hydrofluoric acid in water, put in a magnetic stirrer, stir at room temperature, take out the stirrer, and put it into a polytetrafluoroethylene Lining, then put into the reactor, heat up, heat preservation, obtain cobalt / iron coordination polymer;

[0029] S2, calcining the cobalt / iron coordination polymer in a tube furnace, and obtaining tricobalt tetroxide-ferric oxide composite oxide after natural cooling;

[0030] Wherein, in S1, the stirring time is 0.5h;

[0031] In S1, the heat preservation temperature is 170°C;

[0032] In S1, the holding time is 72h.

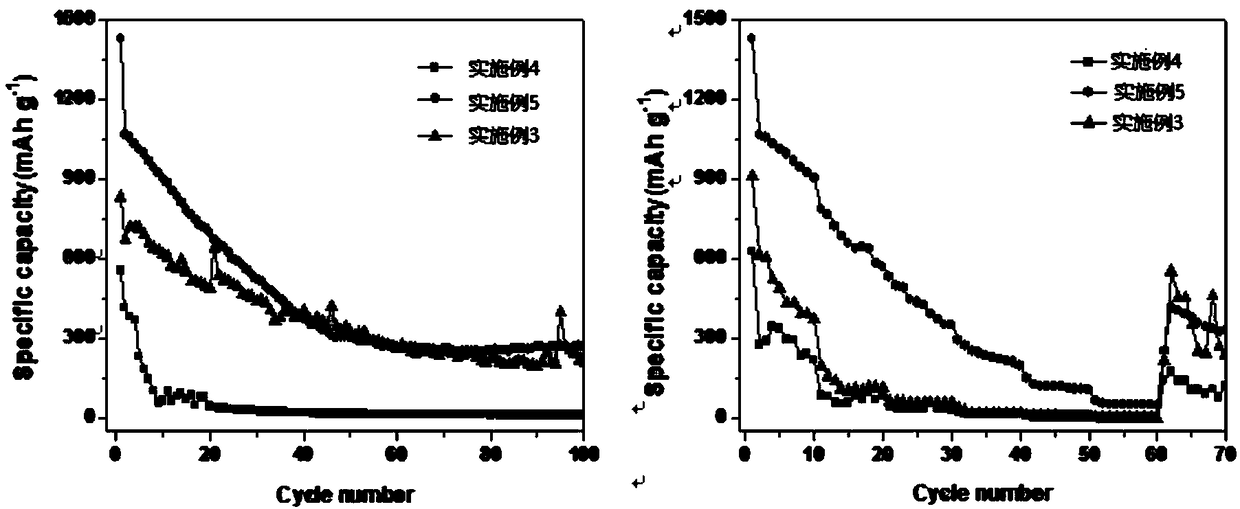

Embodiment 3

[0034] A preparation method of tricobalt tetroxide-ferric oxide composite oxide, comprising the steps of:

[0035] S1. Co-dissolve cobalt dichloride, ferric nitrate, 1,3,5-benzenetricarboxylic acid, and hydrofluoric acid in water, put in a magnetic stirrer, stir at room temperature, take out the stirrer, and put it into a polytetrafluoroethylene Lining, then put into the reactor, heat up, heat preservation, obtain cobalt / iron coordination polymer;

[0036] S2, calcining the cobalt / iron coordination polymer in a tube furnace, and obtaining tricobalt tetroxide-ferric oxide composite oxide after natural cooling;

[0037] Wherein, in S1, the stirring time is 3h;

[0038] In S1, the heat preservation temperature is 160°C;

[0039] In S1, the holding time is 80h;

[0040] In S2, calcining is carried out in the atmosphere of air;

[0041] In S2, during the calcination process, the heating rate is 1°C / min;

[0042] In S2, the calcination temperature is 600°C;

[0043] In S2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com