Medium material for ceramic capacitors

A technology of ceramic capacitors and dielectric materials, applied in the field of electronic materials, can solve the problems of difficult control of product uniformity, complex composition, and many doped substances, and achieve excellent performance, increased dielectric properties, and small changes in temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

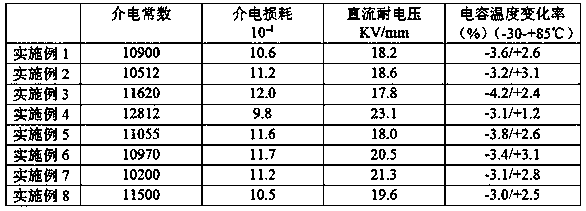

Examples

Embodiment 1

[0023] A dielectric material for ceramic capacitors, mainly made of the following raw materials in parts by weight: 15 parts of strontium carbonate, 25 parts of barium carbonate, 35 parts of butyl titanate, 0.2 part of zirconium n-butoxide, 0.8 part of glass fiber, manganese nitrate 0.2 parts and polyethylene glycol 0.5 parts.

[0024] The dielectric material for the ceramic capacitor is prepared by the following steps:

[0025] (1) Dissolve strontium carbonate and barium carbonate in citric acid solution, stir at 55°C for 20 minutes, then add manganese nitrate to form mixture I;

[0026] (2) Dissolving butyl titanate in 3 times the weight of glycerol to form mixture II;

[0027] (3) Add mixture II to mixture I, and add zirconium n-butoxide and polyethylene glycol with stirring in turn, control the temperature of the system at 85-90°C, and stir until a gel is formed;

[0028] (4) The gel is dried at 95-105°C for 10 hours and then calcined at 850-900°C for 2 hours to form a d...

Embodiment 2

[0032] A dielectric material for ceramic capacitors, mainly made of the following raw materials in parts by weight: 16 parts of strontium carbonate, 20 parts of barium carbonate, 30 parts of butyl titanate, 0.22 parts of zirconium n-butoxide, 0.75 parts of glass fiber and manganese nitrate 0.22 parts, polyethylene glycol 0.45 parts.

[0033] The dielectric material for the ceramic capacitor is prepared by the following steps:

[0034] (1) Dissolve strontium carbonate and barium carbonate in citric acid solution, stir at 55°C for 20 minutes, then add manganese nitrate to form mixture I;

[0035] (2) Dissolving butyl titanate in 3 times the weight of glycerol to form mixture II;

[0036] (3) Add mixture II to mixture I, and add zirconium n-butoxide and polyethylene glycol with stirring in turn, control the temperature of the system at 85-90°C, and stir until a gel is formed;

[0037] (4) The gel is dried at 95-105°C for 10 hours and then calcined at 850-900°C for 2 hours to fo...

Embodiment 3

[0041] A dielectric material for ceramic capacitors, mainly made of the following raw materials in parts by weight: 18 parts of strontium carbonate, 18 parts of barium carbonate, 35 parts of butyl titanate, 0.25 parts of zirconium n-butoxide, 0.7 parts of glass fiber and manganese nitrate 0.25 parts, polyethylene glycol 0.4 parts.

[0042] The dielectric material for the ceramic capacitor is prepared by the following steps:

[0043] (1) Dissolve strontium carbonate and barium carbonate in citric acid solution, stir at 55°C for 20 minutes, then add manganese nitrate to form mixture I;

[0044] (2) Dissolving butyl titanate in 3 times the weight of glycerol to form mixture II;

[0045] (3) Add mixture II to mixture I, and add zirconium n-butoxide and polyethylene glycol with stirring in turn, control the temperature of the system at 85-90°C, and stir until a gel is formed;

[0046] (4) The gel is dried at 95-105°C for 10 hours and then calcined at 850-900°C for 2 hours to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com