Preparation method of ocean agar oligosaccharide yellow rice wine with health care function

An oligosaccharide and agar technology, which is applied in the field of preparation of marine agar-oligosaccharide rice wine with health-care functions, can solve the problems of hidden dangers of food safety, easy generation of by-products, threats of environmental pollution, etc., and achieves the improvement of nutritional and health care value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 contains the preparation of polymerization degree 8-30 agar oligosaccharide rice wine

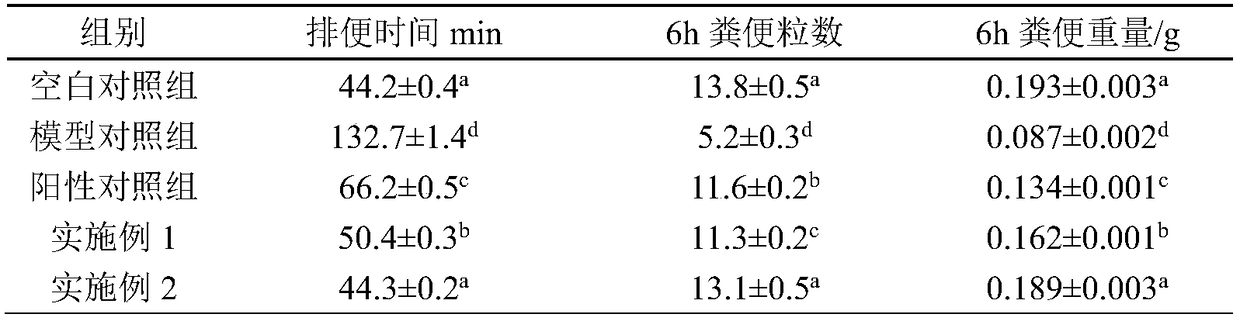

[0023] Prepare 1L of 15% concentration agar suspension, add 10% citric acid and mix evenly, place in 80°C water bath and keep warm for 60min. Add 80g of calcium carbonate and 1mL of defoamer (polyethylene glycol) to the degradation liquid system after the heat preservation is completed, and stir for 60 minutes. The reaction was completed by centrifuging at 8000 rpm for 10 min, and the supernatant and precipitate were placed separately. Take 20kg of millet for washing, soaking, steaming and spreading the rice. When the raw material is cooled to about 60°C, add bran koji or glucoamylase, fully stir and keep warm for saccharification for 30 minutes. After saccharification, cool down to 30°C, add yeast and agar hydrolyzed supernatant, and drop into tank for fermentation. During the fermentation process, start raking in time, adjust the temperature of the fermentation syste...

Embodiment 2

[0024] Embodiment 2 contains the preparation of polymerization degree 8-30 agar oligosaccharide rice wine

[0025] Prepare 1L of 15% concentration agar suspension, add 10% citric acid and mix evenly, place in 80°C water bath and keep warm for 60min. Add 80g of calcium carbonate and 1mL of defoamer (polyethylene glycol) to the degradation liquid system after the heat preservation is completed, and stir for 60 minutes. The reaction was completed by centrifuging at 8000 rpm for 10 min, and the supernatant and precipitate were placed separately. Take 20kg of millet for cleaning, soaking, steaming and spreading the rice. When the raw material is cooled to about 60°C, add 0.1kg of crushed saw fern leaves, add bran yeast or glucoamylase, stir and keep warm for saccharification for 30 minutes. After saccharification, cool down to 30°C, add yeast and agar hydrolyzed supernatant, and drop into tank for fermentation. During the fermentation process, start raking in time, adjust the tem...

Embodiment 3

[0026] Embodiment 3 contains the preparation of polymerization degree 2-8 agar oligosaccharide rice wine

[0027] Prepare 1 L of 10% concentration agar suspension, add 15% citric acid and mix evenly, place in a sterilizing pot at 100°C and keep warm for 90 minutes. Add 120g of calcium carbonate and 1mL of defoamer (polyethylene glycol) to the degradation liquid system after the heat preservation is completed, and stir for 60 minutes. The reaction was completed by centrifugation at 1000 rpm for 10 min, and the supernatant and precipitate were placed separately. Take 20kg of millet for washing, soaking, steaming and spreading the rice. When the raw material is cooled to about 60°C, add bran koji or glucoamylase, fully stir and keep warm for saccharification for 30 minutes. After saccharification, cool down to 30°C, add yeast and agar hydrolyzed supernatant, and drop into tank for fermentation. During the fermentation process, start raking in time, adjust the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com