Preparation method of epitaxial material of silicon-based nanometer laser array with electrically-injected long wavelength

A nano-laser, epitaxial material technology, applied in metal material coating process, active area structure, gaseous chemical plating and other directions, can solve problems affecting the crystal quality of epitaxial layer, limit device performance and stability, etc. Mass mass production, the effect of reducing dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

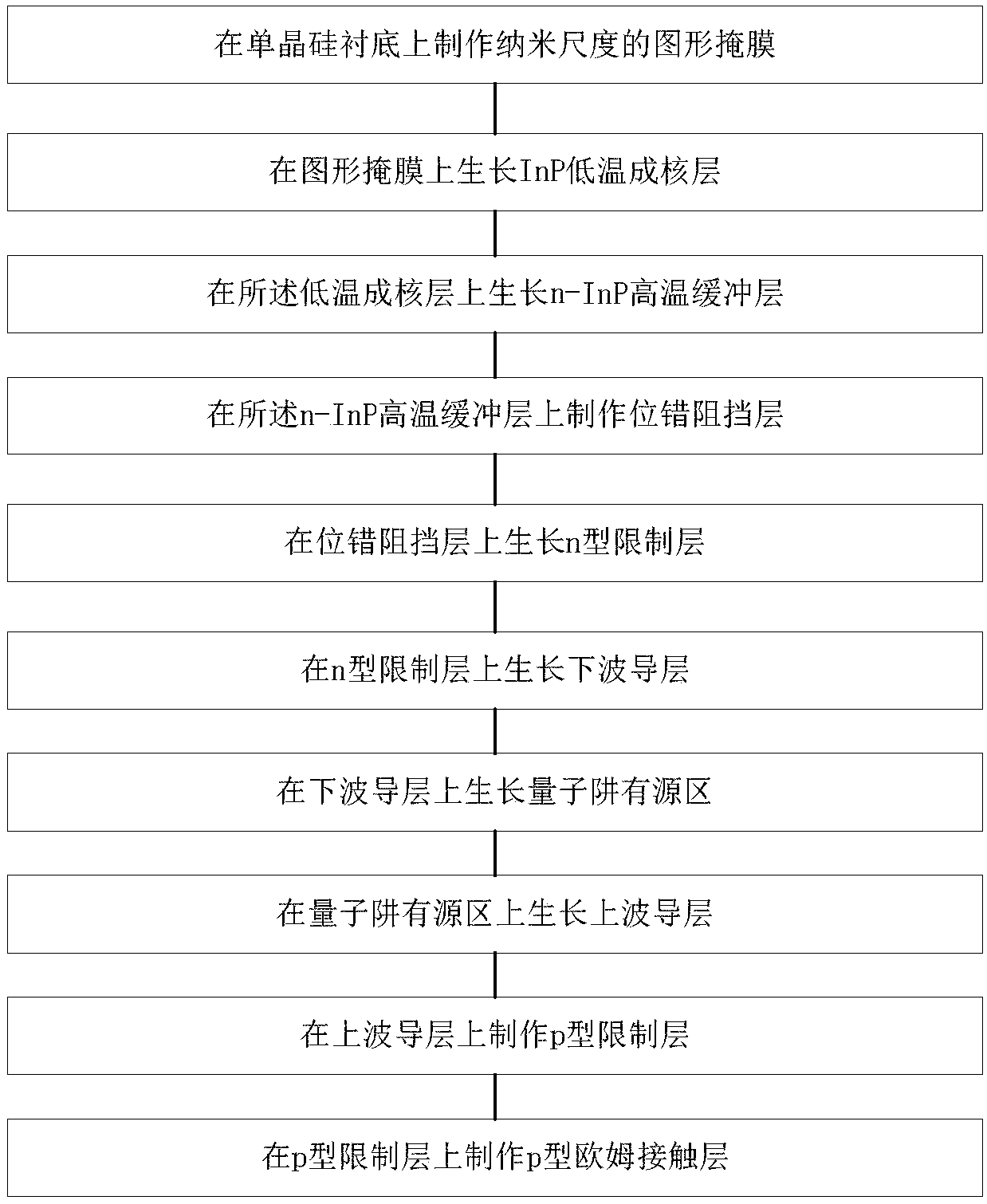

[0044] This embodiment provides a silicon-based nanolaser array epitaxy method for electrical injection with a long wavelength (1.3 μm to 1.6 μm), including:

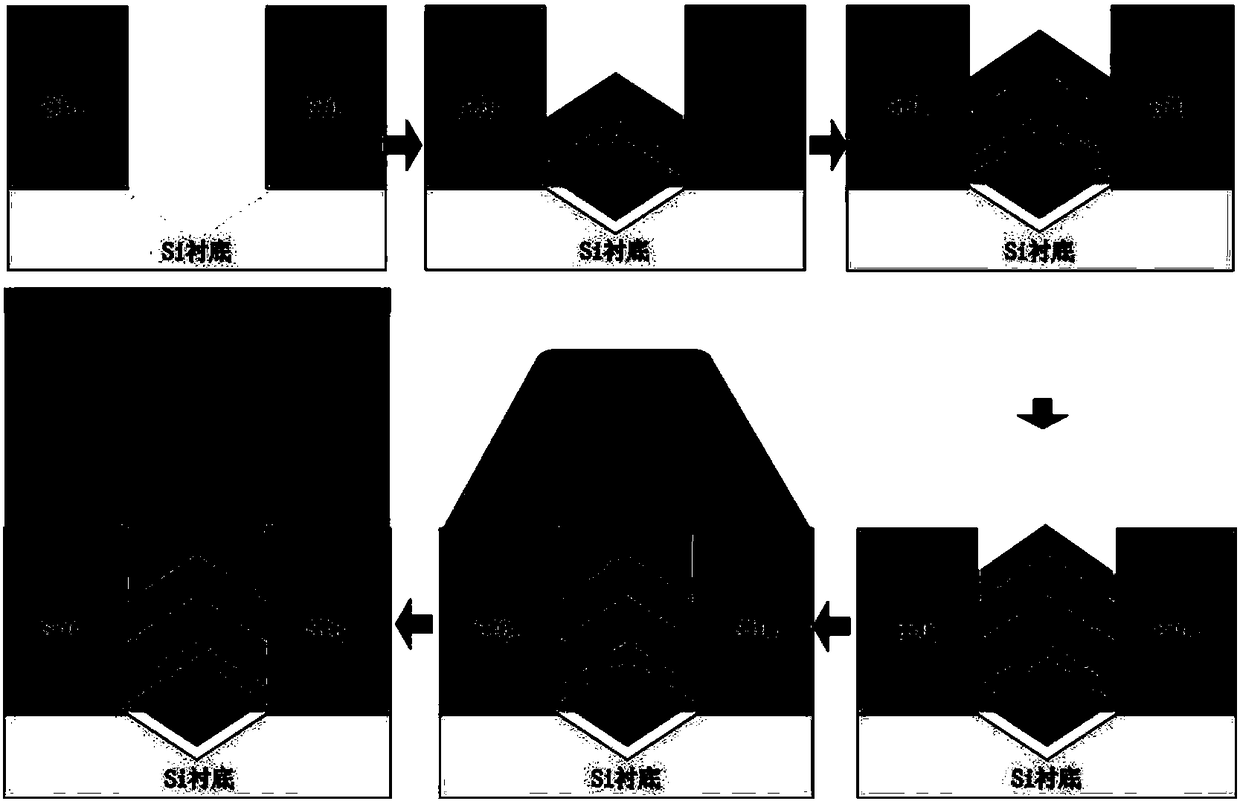

[0045] S1. Fabricate a nanometer-sized graphic mask on a single crystal silicon substrate by plasma-enhanced chemical vapor deposition PECVD method, dry etching technology and wet etching technology;

[0046] S2. Based on the metal organic compound chemical vapor deposition MOCVD method, sequentially fabricate an InP low-temperature nucleation layer, an n-InP high-temperature buffer layer, a dislocation barrier layer, an n-type confinement layer, a lower waveguide layer, and a quantum well layer on the pattern mask....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com