A bisphosphonate drug-intercalated hydrotalcite medical magnesium alloy coating and its preparation method and application

A bisphosphonate and hydrotalcite technology, applied in coatings, medical science, prostheses, etc., to achieve the effect of strong coating binding force, improved compactness and corrosion resistance, and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a bisphosphonate drug-intercalated hydrotalcite medical magnesium alloy coating, comprising the following steps:

[0032] Aluminum nitrate, silver nitrate and water are prepared into solution A;

[0033] Bisphosphonate and water are prepared as Solution B;

[0034] After mixing solution A and solution B, adjust the pH value to 11.5-12.5 to obtain a precursor emulsion;

[0035] The Mg alloy substrate and the precursor emulsion are hydrothermally reacted at 110-125° C. for 10-24 hours to obtain bisphosphonate drug-intercalated hydrotalcite medical magnesium alloy coating.

[0036]In the present invention, there is no special requirement for the preparation sequence of solution A and solution B, which can be carried out simultaneously or separately.

[0037] In the present invention, aluminum nitrate, silver nitrate and water are formulated into solution A. In the present invention, the volume ratio of the amount of aluminum...

Embodiment 1

[0080] (1) Set the surface area to 1cm 2 The magnesium alloy Mg-3Zn-0.8Zr was mechanically polished, and the surface of the sample was polished with 320#, 800#, and 1500# water-grinding sandpaper in turn to remove the oxide layer; placed in acetone and ultrasonically oscillated twice, 20 minutes / time, and then Place in absolute ethanol and ultrasonically vibrate 5 times, 10 minutes each time, and blow dry with cold air.

[0081] (2) Weigh 0.02mol Al(NO 3 ) 3 6H 2 O and 0.015mol AgNO 3 Dissolve in 100mL deionized water to make solution A.

[0082] (3) Weigh 0.005 mol of alendronate sodium and dissolve it in 100 mL of deionized water to prepare solution B. Add solution B dropwise to solution A, stir magnetically for 30 min, add 1 mol / L sodium hydroxide solution, adjust pH=12.5, and obtain precursor emulsion.

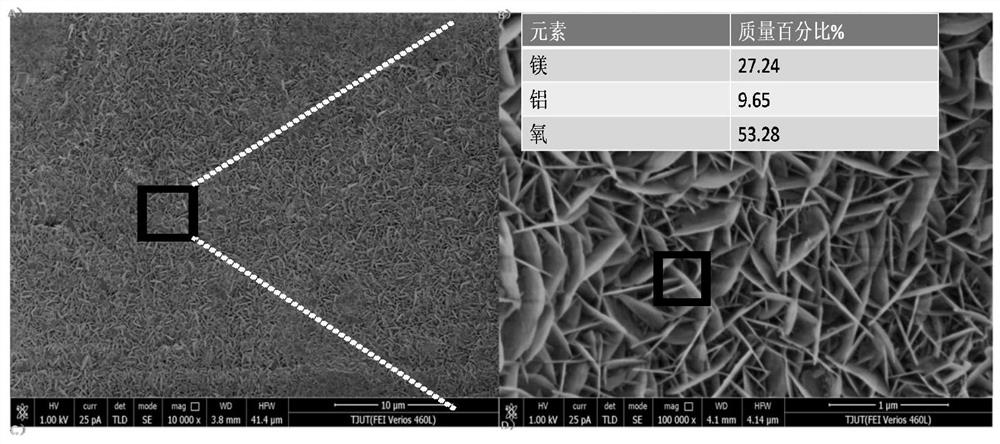

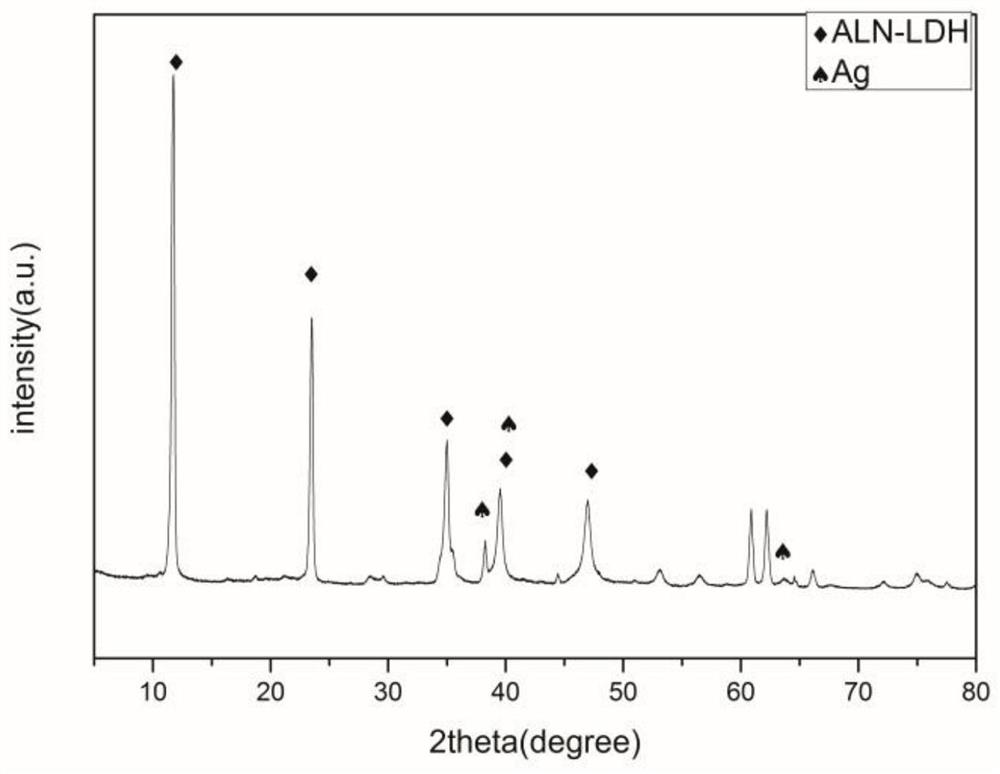

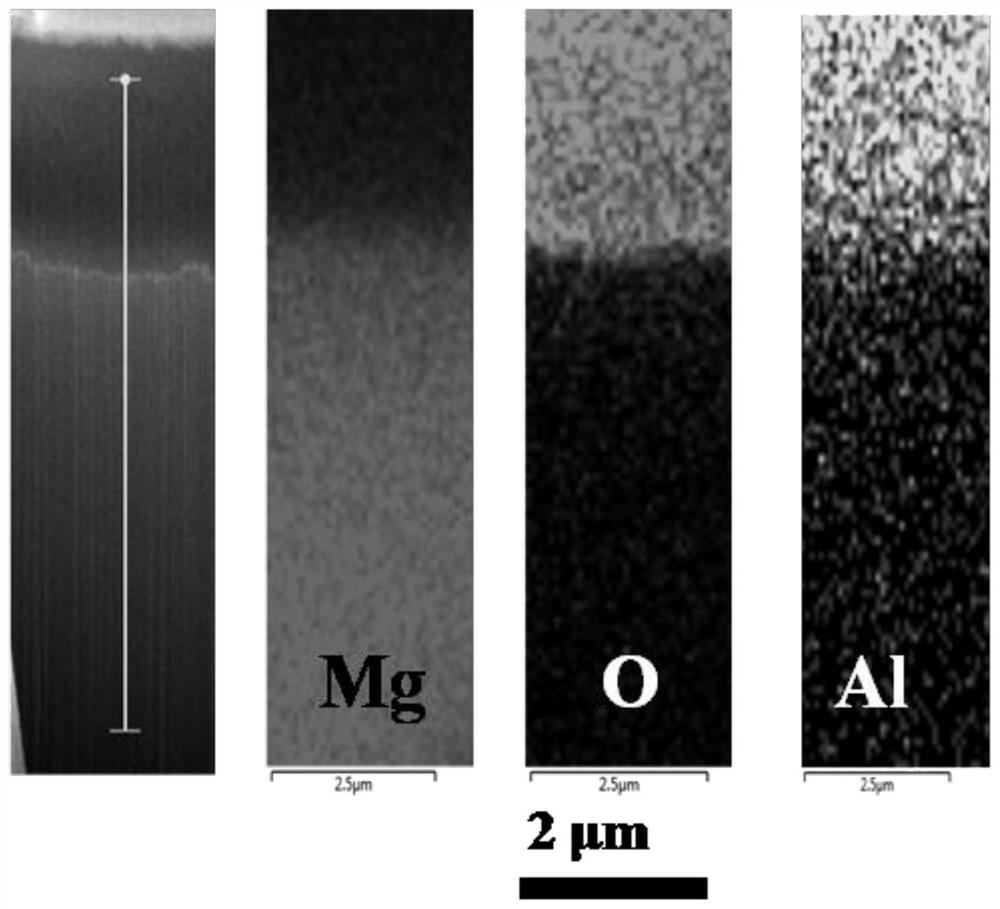

[0083] (4) The purified magnesium alloy substrate and the above precursor emulsion were placed in a hydrothermal reaction kettle, and kept at 125° C. for 10 h to car...

Embodiment 2

[0086] (1) Set the surface area to 1cm 2 The magnesium alloy Mg-3Zn-0.8Zr-0.3Sr was mechanically polished, and the surface of the sample was polished with 320#, 800#, and 1500# water-grinding sandpaper in turn to remove the oxide layer; placed in acetone and ultrasonically oscillated 5 times, 5 minutes / time, and placed in absolute ethanol for 2 times of ultrasonic vibration, 15 minutes each time, and dried with cold air.

[0087] (2) Weigh 0.01mol Al(NO 3 ) 3 6H 2 O and 0.005mol AgNO 3 Dissolve in 50mL deionized water to make solution A.

[0088] (3) Weigh 0.0005 mol of sodium alendronate and dissolve it in 100 mL of deionized water to prepare solution B. Add solution B dropwise to solution A, stir magnetically for 30 min, add 0.5 mol / L sodium hydroxide solution, adjust pH=11.5, and obtain precursor emulsion.

[0089] (4) Put the purified magnesium alloy substrate and the above-mentioned treatment in a hydrothermal reaction kettle, and heat it at 110° C. for 12 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com