A kind of preparation method of cement-based composite insulation board

A composite thermal insulation, cement-based technology, applied in the field of building materials, can solve problems such as poor mechanical properties and thermal insulation properties, and achieve the effects of improving mechanical properties, reducing pore channels, and improving thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

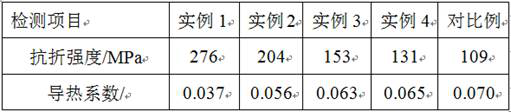

Examples

example 1

[0021]Put the rice husk into the steam explosion tank, and after maintaining the pressure for 30s, open the discharge valve of the steam explosion tank, so that the material in the steam explosion tank is instantly depressurized and sprayed into the receiving tank to obtain rice husk slag, and then the rice husk slag is Put sulfuric acid with a mass fraction of 98% in a No. 1 beaker at a mass ratio of 1:20, stir, mix and carbonize for 60 minutes at a speed of 500 r / min to obtain a No. 1 mixed solution, and then filter the No. 1 mixed solution to obtain No. 1 filter residue, then put the No. 1 filter residue in an oven, and dry it to a constant weight at a temperature of 110°C to obtain carbonized rice husk fibers; add chitosan and water into a single-necked flask at a mass ratio of 1:100 , after stirring and mixing with a glass rod for 30 minutes, let it stand for swelling for 4 hours, then move the single-necked flask into a digital speed measuring constant temperature magneti...

example 2

[0023] Add chitosan and water into a single-necked flask at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the single-necked flask into a digital speed measuring constant temperature magnetic stirrer at a temperature of 85°C and a speed of Under the condition of 500r / min, heat and stir to dissolve for 50min to obtain chitosan liquid; place diatomite in a ball mill for ball milling, pass through a 70-mesh sieve to obtain pretreated diatomite; mix pretreated diatomite with mass fraction Put 30% hydrochloric acid in a three-necked flask at a mass ratio of 1:20, stir and mix for 50 minutes at a rotating speed of 500r / min to obtain a mixed slurry, and then filter the mixed slurry to obtain diatomite for primary treatment. Diatomaceous earth and chitosan solution were placed in No. 2 beaker at a mass ratio of 1:20, and stirred and mixed for 50 minutes at a rotating speed of 500r / min to obtain No. 2 mixed solut...

example 3

[0025] Put the rice husk into the steam explosion tank, and after maintaining the pressure for 30s, open the discharge valve of the steam explosion tank, so that the material in the steam explosion tank is instantly depressurized and sprayed into the receiving tank to obtain rice husk slag, and then the rice husk slag is Put sulfuric acid with a mass fraction of 98% in a No. 1 beaker at a mass ratio of 1:20, stir, mix and carbonize for 60 minutes at a speed of 500 r / min to obtain a No. 1 mixed solution, and then filter the No. 1 mixed solution to obtain No. 1 filter residue, then put the No. 1 filter residue in an oven, and dry it to a constant weight at a temperature of 110°C to obtain carbonized rice husk fibers; add chitosan and water into a single-necked flask at a mass ratio of 1:100 , after stirring and mixing with a glass rod for 30 minutes, let it stand for swelling for 4 hours, then move the single-necked flask into a digital speed measuring constant temperature magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com