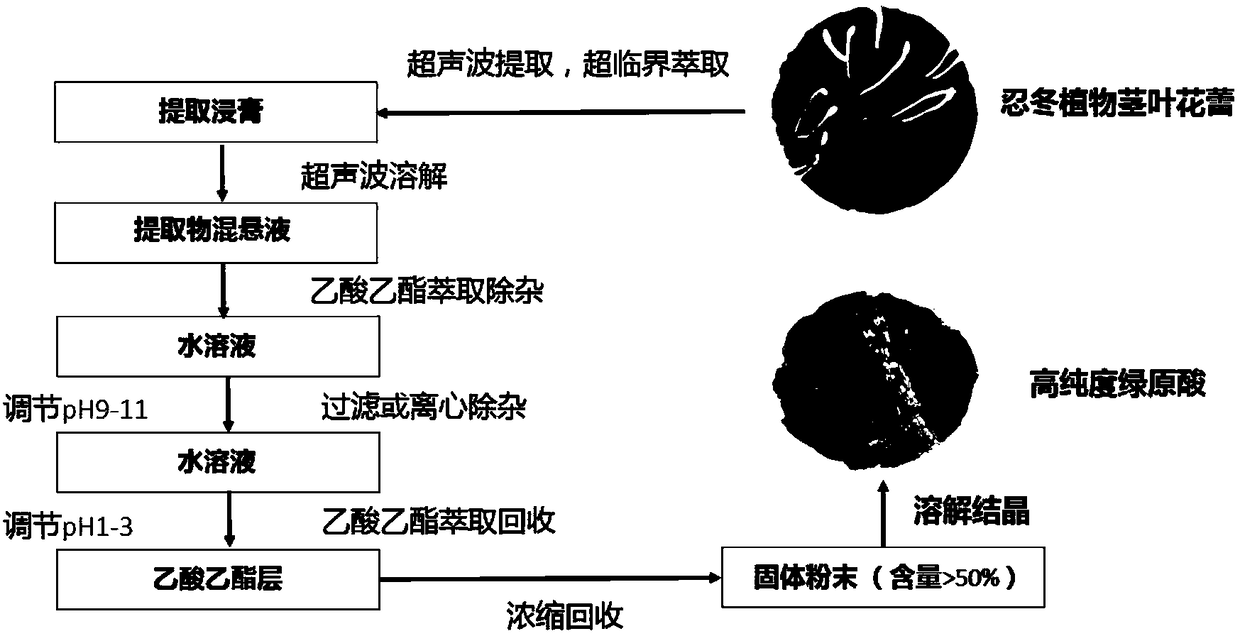

Method for preparing high-purity chlorogenic acid by taking lonicera plants as raw materials

A technology of chlorogenic acid and honeysuckle, applied in the field of medicine and chemical industry, can solve the problems of large amount of organic solvent, high purification cost, time-consuming and laborious, etc., and achieve the effect of simple operation, wide sources and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

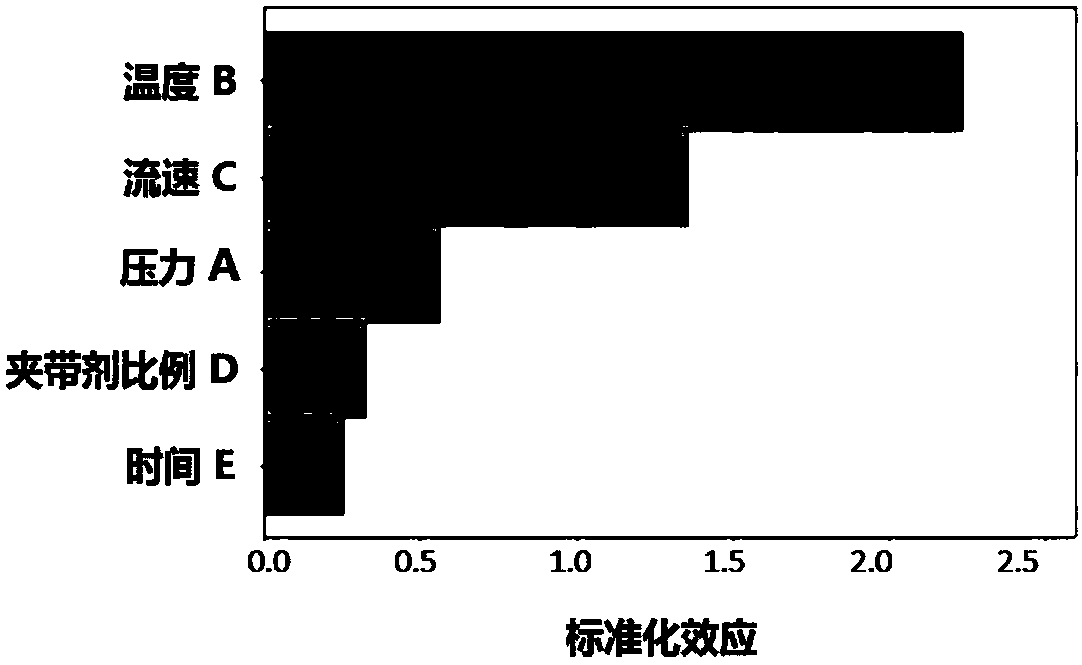

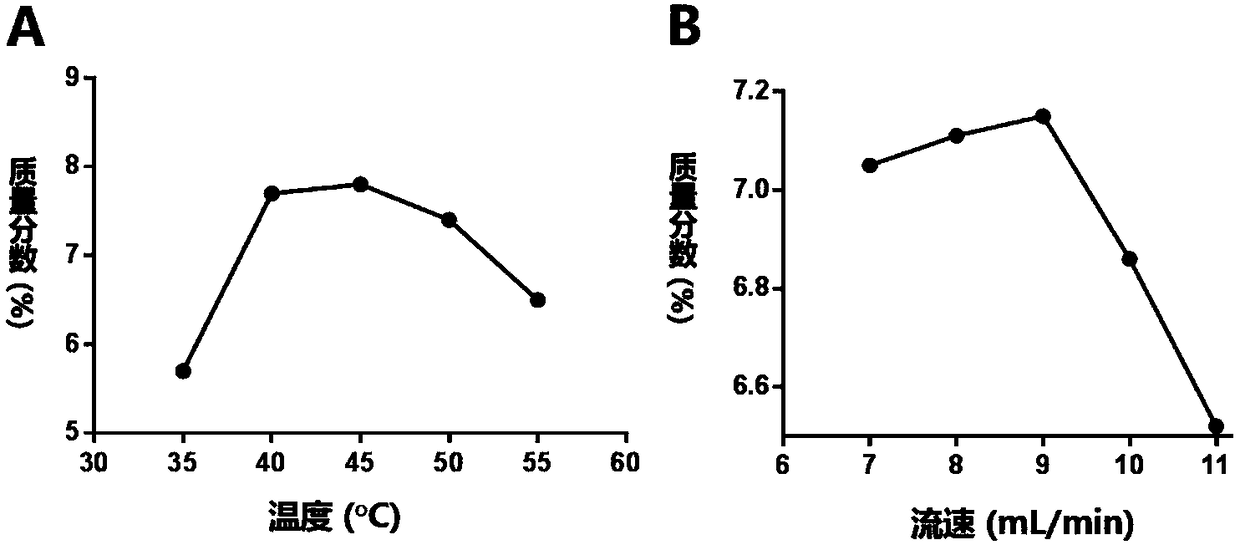

[0036] Embodiment 1. Investigation and implementation of supercritical carbon dioxide extraction process

[0037] Due to the instability of chlorogenic acid, high temperature, strong light and long-term heating cannot be used during extraction, so supercritical fluid extraction is an ideal method. The present invention takes the extraction rate of chlorogenic acid as an index, utilizes the orthogonal test method and the response surface design method to optimize the process conditions of supercritical fluid extraction, and takes the Lonicera japonica Thunb. planted in Julu County, Hebei Province The branches and leaves of the plant were used as raw materials, dried at 50°C for 12 hours, pulverized with a high-speed pulverizer, and passed through a 20-mesh sieve. The content of chlorogenic acid was measured by HPLC method, instrument: Shimadzu high performance liquid chromatography LC-15C, equipped with binary pump, SPD-15C ultraviolet detector, CTO-15C column thermostat, LC-So...

Embodiment 2

[0051] Example 2. Extraction of Chlorogenic Acid in Flos Lonicerae by Ultrasonic Method

[0052] Take the stem and leaf of Lonicera hypoglauca Miq. produced in Xincheng County, Guangxi as the raw material of Lonicera hypoglauca Miq. As raw material, get its powder 10g, add 70% ethanol solution of 1:30 (W / V) volume ratio, Ultrasonic power is 300W, ultrasonic frequency is 60KHz, ultrasonic extraction is 30 minutes, after filtration, depressurization is concentrated to obtain chlorogenic acid extract 1.95g, and adopt the HPLC method in the above-mentioned embodiment 1 to detect wherein the chlorogenic acid content can reach 5.9% .

Embodiment 3

[0053] Embodiment 3. The investigation of alkali removal and purification process

[0054] Take 0.76 g of the chlorogenic acid extraction extract obtained by the ultrasonic method in the above-mentioned Example 2, add 30 mL of deionized water, and ultrasonically dissolve it fully for 30 minutes. Repeated extraction was carried out with one volume of ethyl acetate respectively until the ethyl acetate layer was colorless and clear (5 times in total). Take the water layer, divide it into 6 parts on average, adjust the pH to 6~11 with NaOH respectively, let it settle for 3 hours, then centrifuge at 3000rpm for 10 minutes, and dry and weigh the obtained insoluble precipitate to investigate the efficiency of alkali removal. The result is as Figure 5 As shown, it is confirmed that the optimum pH of the alkali removal process is 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com