Radio frequency micro-strip structure for Ti/Ni/Ag material system

A system, radio frequency technology, applied in semiconductor devices, electrical solid state devices, semiconductor/solid state device components, etc., can solve problems such as substrate vacuum leakage, high aspect ratio via hole etching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

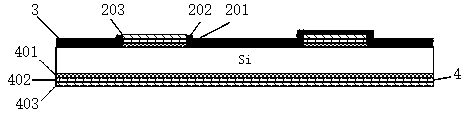

[0050] As shown in Figure 4(a)-(c), it is the three-dimensional top view of the RF microstrip structure of the Ti / Ni / Ag material system applied to the RF microstrip line filter and the top view of the RF substrate integrated waveguide filter.

[0051] In practical application, the present invention is applicable to (a) inductive column substrate integrated waveguide filter, (b) circular cavity substrate integrated waveguide filter, (c) rectangular cavity cross-coupled substrate integrated waveguide filter, ( d) Inline microstrip bandpass filter, (e) Parallel coupled microstrip bandpass filter, (f) Interdigitated microstrip bandpass filter, (g) Hairpin microstrip bandpass filter pass filter. ((a)-(c) filter includes W cover layer, passivation layer, front Ti / Ni / Ag metal stack, Si substrate, back metal layer. (d)-(g) filter includes passivation layer , front Ti / Ni / Ag metal stack, Si substrate, and back metal layer. Among them, the front Ti / Ni / Ag metal stack has an image; the Si...

Embodiment 2

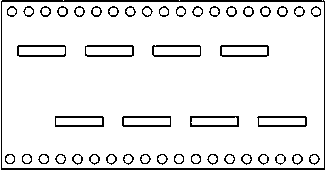

[0055] As shown in Figure 5(a)-(c), it is a three-dimensional top view of a microstrip line filter or antenna patterned into a split ring structure applied to the front Ti / Ni / Ag metal stack.

[0056]In practical application, the present invention is applicable to a microstrip line filter or antenna formed by split rings, each split ring constitutes a microstrip resonator, and the split ring resonators are achieved through different forms of coupling and different gaps. Positive and negative coupling and the magnitude of the corresponding coupling. As shown in Figure 5(a) is a hybrid coupling form, adjusting the gap between the resonators and the position offset of the resonators can change the coupling size. The resonant unit in Fig. 5(b) is a miniaturized microstrip split ring resonator. This kind of resonator makes full use of the space inside the ring under the premise of ensuring that the total length of the microstrip line is approximately half a wavelength. Part of the ...

Embodiment 3

[0059] Such as Figure 6 Shown is the top view of the RF microstrip structure of the Ti / Ni / Ag material system applied to the directional coupler.

[0060] In practical application, the present invention is applicable to radio frequency microstrip directional couplers. The radio frequency microstrip directional coupler includes a W covering layer, a passivation layer, a front Ti / Ni / Ag metal stack, a Si substrate, and a back metal layer. Among them, the front Ti / Ni / Ag metal stack has an image; the Si substrate is high-resistance Si. In addition, the transition between the SIW and the microstrip line of the RF microstrip directional coupler uses a transition zone in a gradual form composed of Ti / Ni / Ag metal stacks.

[0061] The general processing steps of the present invention are: first use low concentration hydrochloric acid, SPM (H 2 SO 4 +H 2 o 2 ) Clean the surface of the Si substrate to reduce the surface state of the silicon wafer, improve the surface hydrophilicity,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com