Method for transferring single graphene layer based on degradable polymer

A technology for degrading polymers and single-layer graphene, applied in the direction of single-layer graphene, graphene, nano-carbon, etc., can solve problems such as polymer residues, and achieve easy film formation, good film formation effect, and biocompatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

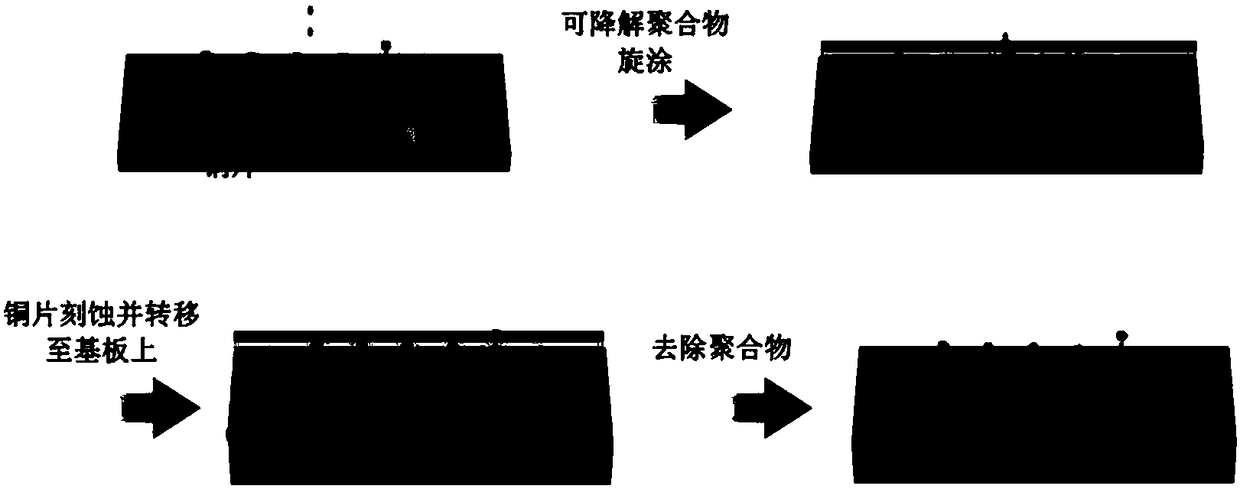

Method used

Image

Examples

Embodiment 1

[0026] (1) The preparation concentration is the polylactic acid solution of 20wt%, and preparation method is that polylactic acid is dissolved in the dichloromethane. The silicon wafer of the target substrate needs to be deoxidized before use, ultrasonically in acetone, ethanol, and water for about 30 minutes, and then in hydrofluoric acid solution (HF:H 2 O volume ratio is 1:50) in soaking 2.5min.

[0027] (2) Cut the graphene / copper sheet of suitable size and fix it on the glass slide with adhesive tape to prevent the graphene / copper sheet from curling. Place the glass slide loaded with the graphene / copper sheet on the spin coating apparatus, set the spin coating speed to 4000rpm, and the spin coating time to 40s. After the spin coating was finished, the slide glass was taken out and dried in a natural state for 15 minutes. Polylactic acid formed a film on the surface of graphene naturally, and the thickness of the polylactic acid film was 0.3 μm.

[0028] (3) The graphene...

Embodiment 2

[0034](1) preparation concentration is the polylactic acid solution of 10wt%, and preparation method is that polylactic acid is dissolved in methylene chloride. The silicon dioxide on the target substrate needs to be deoxidized before use. It is ultrasonicated in acetone, ethanol, and water for about 60 minutes, and then in hydrofluoric acid solution (HF:H 2 O volume ratio is 1:50) in soaking 5min.

[0035] (2) Cut the graphene / copper sheet of suitable size and fix it on the glass slide with adhesive tape to prevent the graphene / copper sheet from curling. Place the glass slide loaded with the graphene / copper sheet on the spin coating apparatus, set the spin coating speed to 3000rpm, and the spin coating time to 50s. After the spin coating was finished, the lower glass slide was taken out and dried in a natural state for 30 minutes. Polylactic acid formed a film on the surface of graphene naturally, and the thickness of the polylactic acid film was 0.1 μm.

[0036] (3) The gr...

Embodiment 3

[0042] (1) preparation concentration is the polylactic acid solution of 30wt%, and preparation method is that polylactic acid is dissolved in methylene chloride. The silicon carbide of the target substrate needs to be deoxidized before use, ultrasonically in acetone, ethanol, and water for about 10 minutes, and then in hydrofluoric acid solution (HF:H 2 O volume ratio is 1:50) in soaking 1min.

[0043] (2) Cut the graphene / copper sheet of suitable size and fix it on the glass slide with adhesive tape to prevent the graphene / copper sheet from curling. Place the glass slide loaded with graphene / copper sheet on the spin coating apparatus, set the spin coating speed to 3500rpm, and spin coating time to 30s. After the spin coating was completed, the slide glass was taken out and dried in a natural state for 1 min. Polylactic acid naturally formed a film on the graphene surface, and the thickness of the polymer film was 0.5 μm.

[0044] (3) The graphene / copper sheet covered with p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com