Method for preparing nanometer WC powder in conditions of low temperature and short process

A short process, powder technology, applied in the direction of tungsten/molybdenum carbide, carbide, etc., can solve the problems of harsh environment, fine particle size of W powder, easy growth of W powder, etc., to achieve narrow particle size distribution and fine grain size. , The effect of powder composition is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

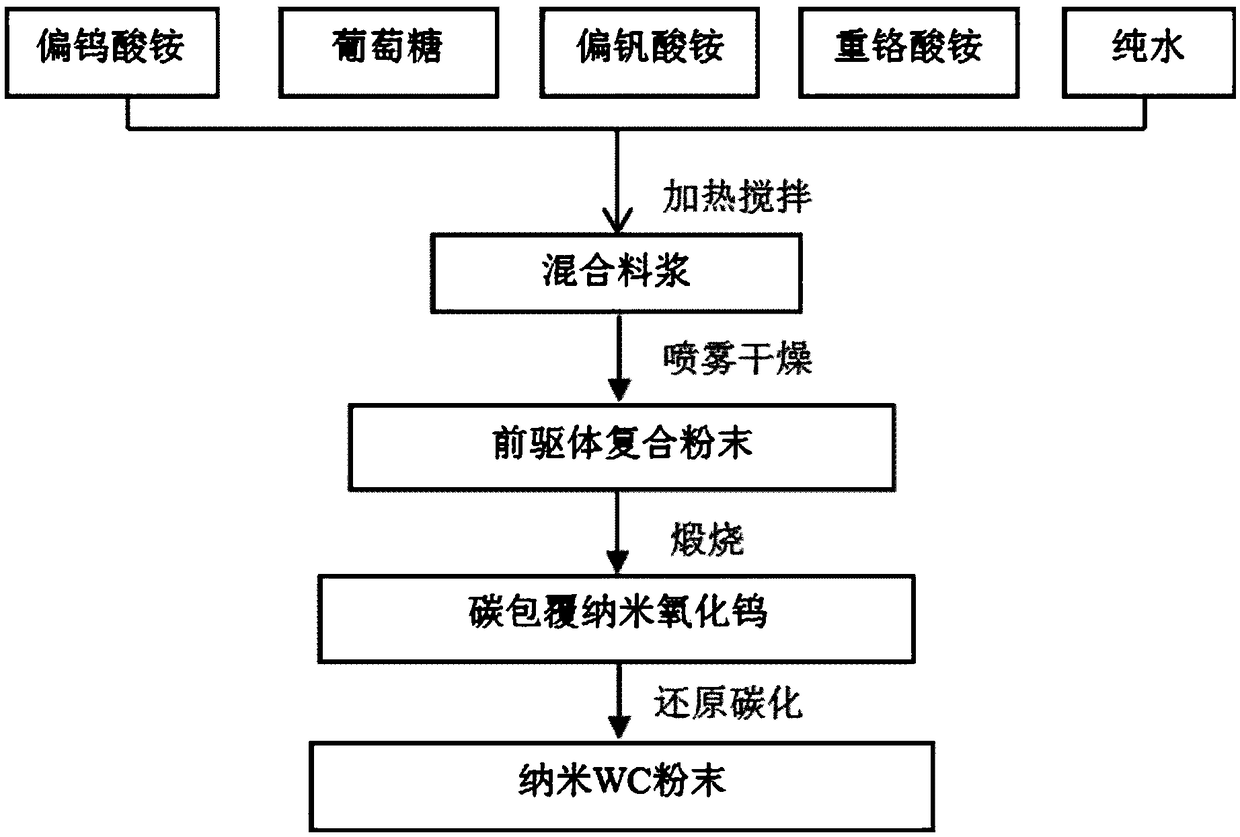

[0032] The present embodiment prepares nano WC powder according to the following steps:

[0033] 1) Ingredients

[0034] Dissolve 100Kg of water-soluble ammonium metatungstate, 54Kg of glucose, 0.6Kg of ammonium metavanadate and 0.9Kg of ammonium dichromate in pure water whose mass is 1.0 times the total mass of solids, and stir evenly at 80°C to obtain a mixture with pH=4. slurry;

[0035] 2) spray drying

[0036] The mixed slurry obtained in step 1) is subjected to centrifugal spray drying to obtain a spherical precursor composite powder. The conditions of the centrifugal spray drying are: the inlet air temperature is 260°C, the outlet air temperature is 140°C, and the atomizer speed is 15000r / min, feed rate 3.4kg / min;

[0037] 3) Calcination

[0038] The spherical precursor composite powder obtained in step 2) was calcined at 600°C for 60 minutes with nitrogen gas, and then the spherical shell was broken by dry ball milling to obtain carbon-coated nano WO 3 powder;

...

Embodiment 2

[0043] The present embodiment prepares nano WC powder according to the following steps:

[0044] 1) Ingredients

[0045]Dissolve 100Kg of water-soluble ammonium metatungstate, 49Kg of glucose, 0.4Kg of ammonium metavanadate and 0.8Kg of ammonium dichromate in pure water whose mass is 0.6 times the total mass of solids, and stir evenly at 60°C to obtain a mixture with pH=3.2 slurry;

[0046] 2) spray drying

[0047] The mixed slurry obtained in step 1) is subjected to centrifugal spray drying to obtain precursor composite powder. The conditions of the centrifugal spray drying are: the inlet air temperature is 260°C, the outlet air temperature is 120°C, and the rotation speed of the atomizer is 12000r / min, feed rate 3.0kg / min;

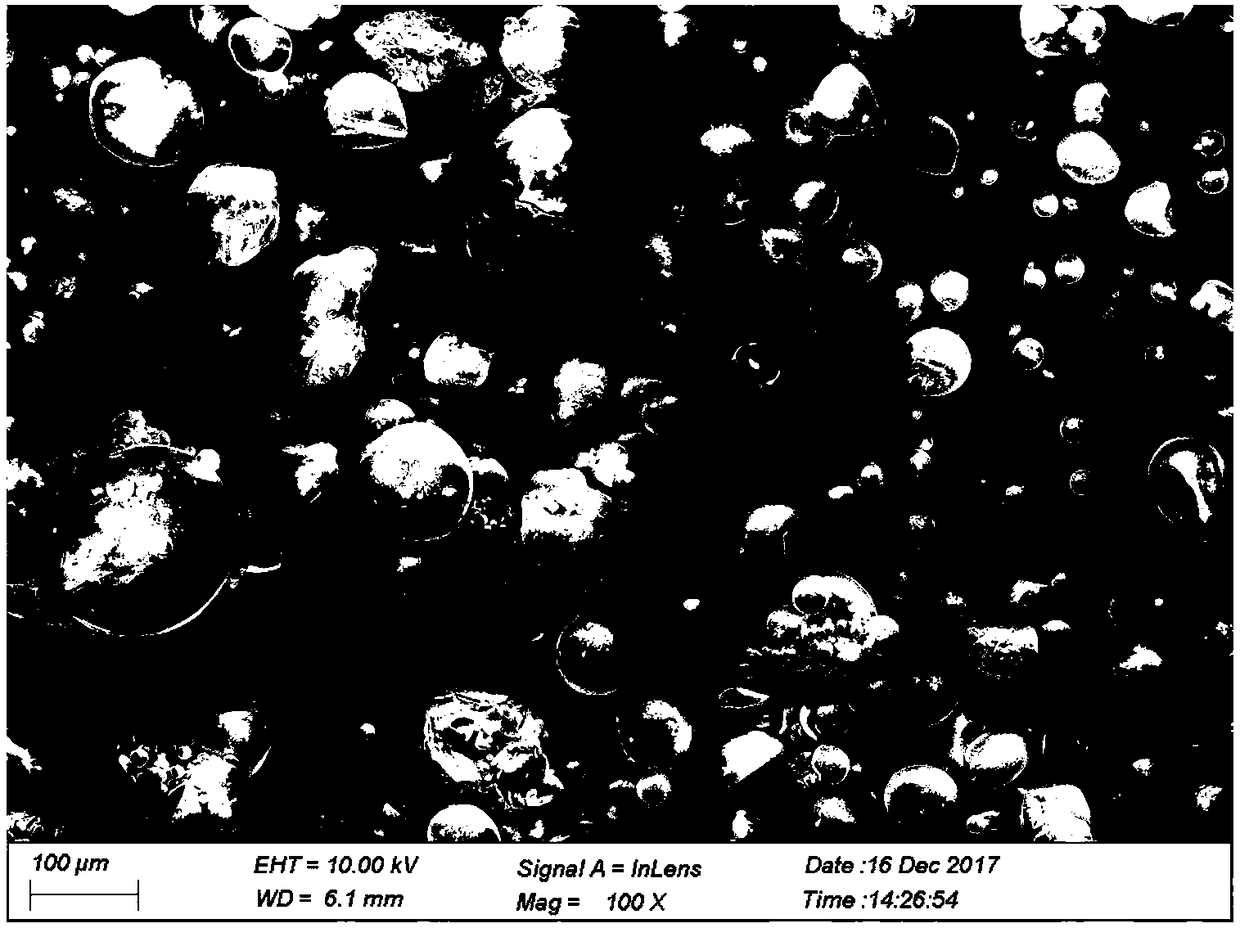

[0048] Scanning electron microscope analysis is carried out to the composite powder of precursor obtained in this embodiment, the result is as follows figure 2 As shown, it can be seen that the obtained precursor composite powder has a spherical st...

Embodiment 3

[0060] The present embodiment prepares nano WC powder according to the following steps:

[0061] 1) Ingredients

[0062] Dissolve 100Kg of water-soluble ammonium metatungstate, 46Kg of glucose, 0.3Kg of ammonium metavanadate and 0.9Kg of ammonium dichromate in pure water whose mass is 0.8 times the total mass of the solid, and stir evenly at =70°C to obtain pH=3.4 mixed slurry;

[0063] 2) spray drying

[0064] The mixed slurry obtained in step 1) is subjected to centrifugal spray drying to obtain spherical precursor composite powder. The conditions of the centrifugal spray drying are: the inlet air temperature is 260°C, the outlet air temperature is 115°C, and the atomizer speed is 10000r / min, feed rate 2.8kg / min;

[0065] 3) Calcination

[0066] The spherical precursor composite powder obtained in step 2) was calcined at 500°C for 80 minutes with nitrogen gas, and then the spherical shell was broken by dry ball milling to obtain carbon-coated nano WO 3 powder;

[0067...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com