Composite material for outer sheath of cable

A technology of composite materials and raw materials, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems such as reduced lifespan, poor ductility, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

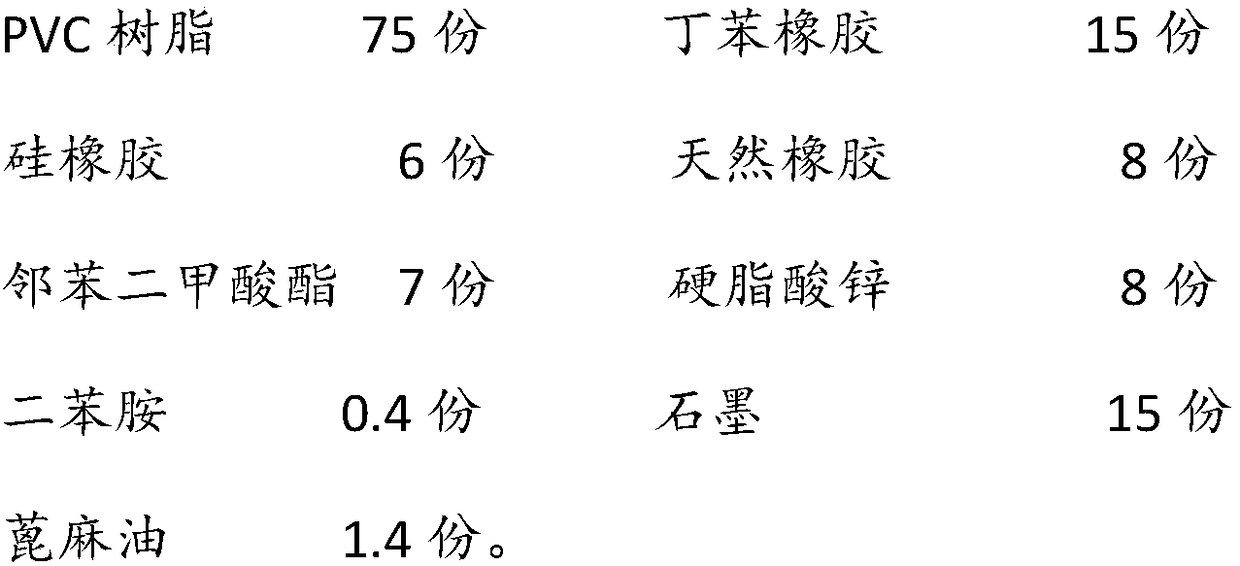

[0019] Composite material for cable outer sheath, its raw material components in parts by mass are:

[0020]

[0021] Its preparation method is:

[0022] Weighing components of PVC resin, styrene-butadiene rubber, silicone rubber, natural rubber, phthalate, zinc stearate, diphenylamine, graphite and castor oil;

[0023] Add natural rubber to the internal mixer, set the temperature of the internal mixer to 45°C, and the rotor speed to 80r / min. After banburying for 7 minutes, add styrene-butadiene rubber and silicon rubber. After banburying for 20 minutes, adjust the temperature of the banbury mixer When the temperature reaches 120°C, PVC resin and graphite are added to the internal mixer, and after internal mixing for 20 minutes, mixture a is obtained;

[0024] Add compound a, phthalate, zinc stearate, diphenylamine and castor oil into a high-speed mixer, set the mixing temperature to 80°C, and mix for 18 minutes to obtain compound b;

[0025] Add compound b into the twin-...

Embodiment 2

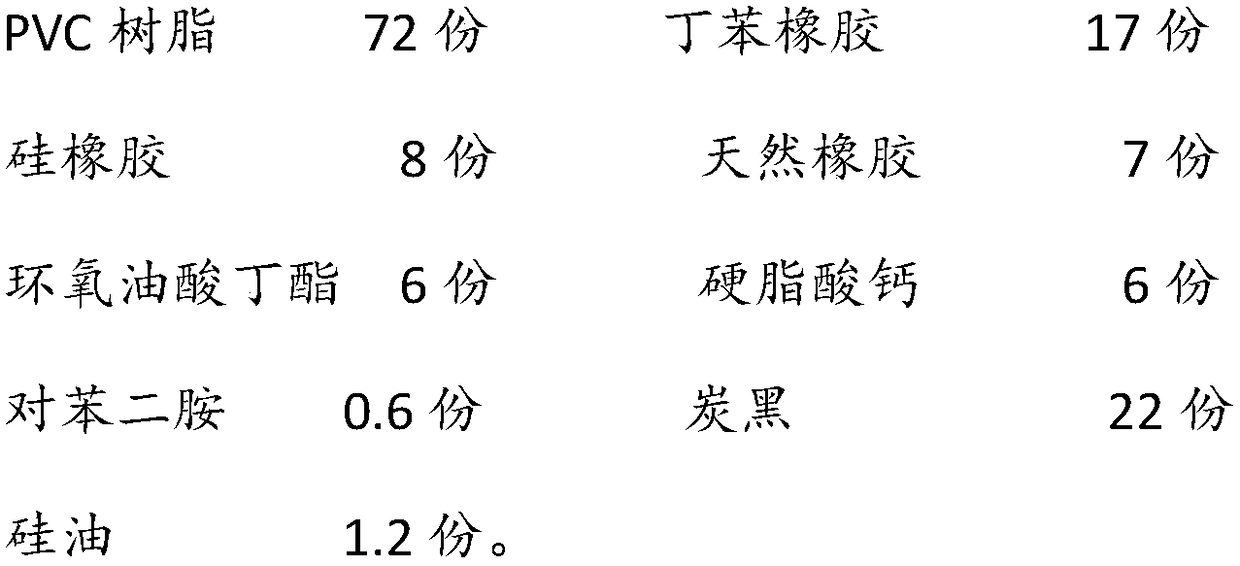

[0027] Composite material for cable outer sheath, its raw material components in parts by mass are:

[0028]

[0029] Its preparation method is:

[0030] Weigh the components of PVC resin, styrene-butadiene rubber, silicone rubber, natural rubber, epoxy butyl oleate, calcium stearate, p-phenylenediamine, carbon black and silicone oil;

[0031] Add natural rubber to the internal mixer, set the temperature of the internal mixer to 63°C, and the rotor speed to 73r / min. After banburying for 6 minutes, add styrene-butadiene rubber and silicon rubber. After banburying for 28 minutes, adjust the temperature of the banbury mixer When the temperature reached 85°C, PVC resin and carbon black were added to the internal mixer, and after internal mixing for 19 minutes, mixture a was obtained;

[0032] Add mixture a, epoxy butyl oleate, calcium stearate, p-phenylenediamine and silicone oil into the high-speed mixer, set the mixing temperature to 90°C, and mix for 16 minutes to obtain mi...

Embodiment 3

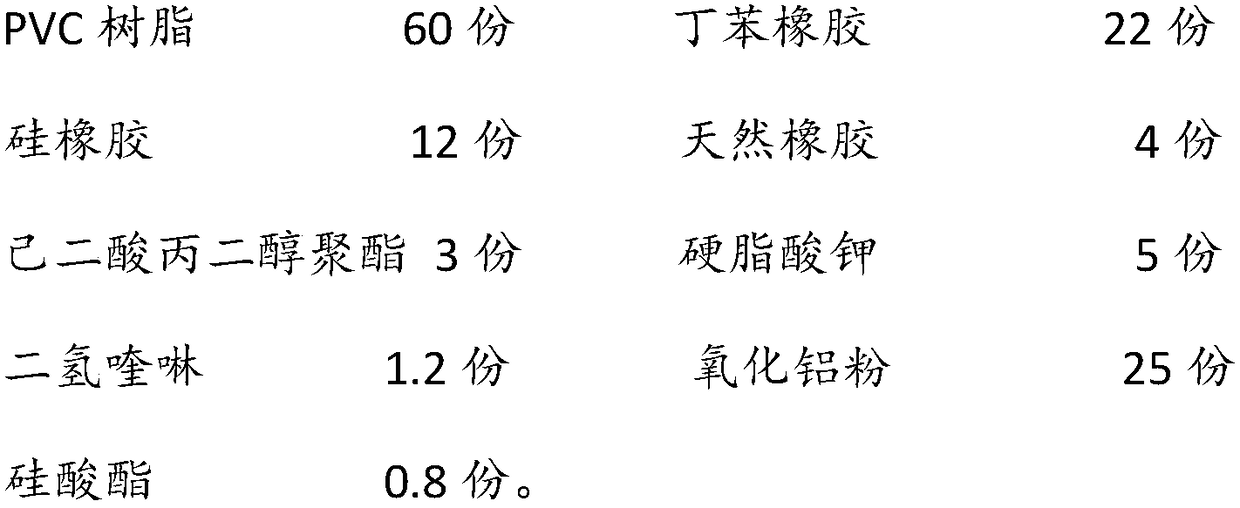

[0035] Composite material for cable outer sheath, its raw material components in parts by mass are:

[0036]

[0037] Its preparation method is:

[0038] Weigh the components of PVC resin, styrene-butadiene rubber, silicone rubber, natural rubber, propylene glycol adipate, potassium stearate, dihydroquinoline, alumina powder and silicate;

[0039] Add natural rubber to the internal mixer, set the temperature of the internal mixer to 65°C, and the rotor speed to 70r / min. After 4 minutes of internal mixing, add styrene-butadiene rubber and silicon rubber. After 30 minutes of internal mixing, adjust the temperature of the internal mixer to When the temperature reached 80°C, PVC resin and alumina powder were added to the internal mixer, and after internal mixing for 15 minutes, mixture a was obtained;

[0040] Add compound a, propylene glycol adipate, potassium stearate, dihydroquinoline and silicate into a high-speed mixer, set the mixing temperature to 110°C, and mix for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com