A kind of sandwich seaweed and its production process

A sandwich seaweed and production process technology, applied in the field of sandwich seaweed and its production process, can solve the problems of low production efficiency, complex production process, easy to stain clothes, etc., and achieve the effect of high production efficiency, simple process, and excellent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

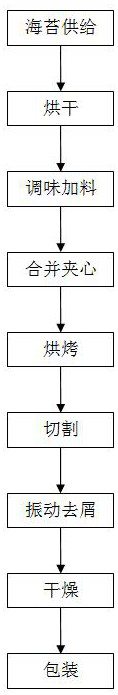

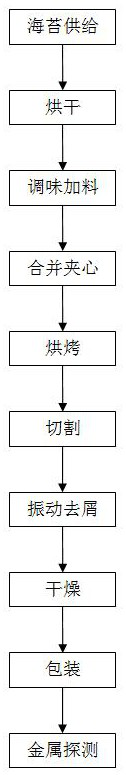

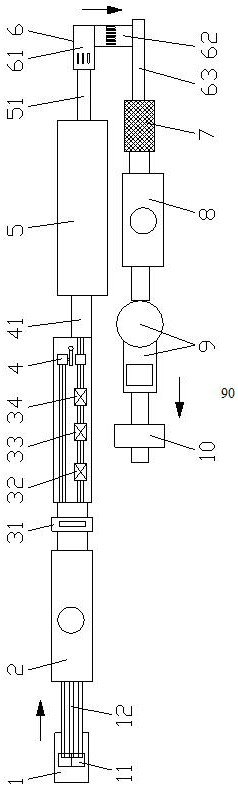

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of sandwich seaweed, including the following raw material components in parts by mass: 20 parts of dried laver, 20 parts of white sesame, 10 parts of nuts, 15 parts of white granulated sugar powdered sugar, 0.5 part of Trehalose, 3.5 parts of maltodextrin, 4.5 parts of fructose syrup, 0.5 parts of vegetable oil, 1 part of edible salt, 0.5 parts of starch, 0.5 parts of brewed soy sauce, 0.25 parts of yeast extract, 0.05 parts of Mushroom essence, 0.25 part of monosodium glutamate and 0.35 part of phospholipid.

[0027] Among them, dried seaweed contains two pieces of seaweed, trehalose, maltodextrin, fructose syrup, vegetable oil, edible salt, starch, brewed soy sauce, yeast extract, mushroom essence, sodium glutamate and phospholipids are stirred and mixed to form a seasoning liquid. The seasoning liquid is evenly coated on the upper surface of the first piece of seaweed, the particle size of the nut kernels, white sesame seeds and white sugar powde...

Embodiment 2

[0038] Embodiment two: a kind of sandwich seaweed, including the following raw material components by mass parts: 24 parts of dried laver, 25 parts of white sesame, 15 parts of nuts, 20 parts of white granulated sugar powdered sugar, 1 part of Trehalose, 4 parts of maltodextrin, 5 parts of fructose syrup, 1 part of vegetable oil, 1.5 parts of edible salt, 1 part of starch, 1 part of brewed soy sauce, 0.5 parts of yeast extract, 0.1 parts of Mushroom essence, 0.5 part of monosodium glutamate and 0.4 part of phospholipid.

[0039] Among them, dried seaweed contains two pieces of seaweed, trehalose, maltodextrin, fructose syrup, vegetable oil, edible salt, starch, brewed soy sauce, yeast extract, mushroom essence, sodium glutamate and phospholipids are stirred and mixed to form a seasoning liquid. The seasoning liquid is evenly coated on the upper surface of the first piece of seaweed, the particle size of the nut kernels, white sesame seeds and white sugar powder decreases in tu...

Embodiment 3

[0051] Embodiment three: a kind of sandwich seaweed, including the following raw material components by mass parts: 25-28 parts of dried laver, 30 parts of white sesame, 18-20 parts of nuts, 25 parts of white granulated sugar powdered sugar , 1.5 parts of trehalose, 4.5 parts of maltodextrin, 5.5 parts of fructose syrup, 1.5 parts of vegetable oil, 2 parts of edible salt, 1.5 parts of starch, 1.5 parts of brewed soy sauce, 0.75 parts of yeast extract , 0.15 parts of mushroom essence, 0.75 parts of monosodium glutamate and 0.45 parts of phospholipids.

[0052] Among them, dried seaweed contains two pieces of seaweed, trehalose, maltodextrin, fructose syrup, vegetable oil, edible salt, starch, brewed soy sauce, yeast extract, mushroom essence, sodium glutamate and phospholipids are stirred and mixed to form a seasoning liquid. The seasoning liquid is evenly coated on the upper surface of the first piece of seaweed, the particle size of the nut kernels, white sesame seeds and whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com