Composite electrode material and preparation method thereof

A composite electrode and mixed solution technology, which is applied in the field of capacitors, can solve the problems of hindering the contact between the electrolyte and the active material, reducing the conductivity of the electrode material, and low specific surface area, so as to facilitate rapid transfer, prevent agglomeration, and increase the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of composite electrode material, comprises the following steps:

[0032] 1) mixing soluble divalent nickel salt, soluble divalent cobalt salt, hexamethylenetetramine, lanthanum manganate and a solvent to obtain a mixed solution;

[0033] 2) adding nickel foam into the mixed solution obtained in the step (1) to carry out a hydrothermal reaction to obtain a precursor;

[0034] 3) Drying and annealing the precursor obtained in the step (2) in sequence to obtain a composite electrode material.

[0035] The invention mixes soluble divalent nickel salt, soluble divalent cobalt salt, hexamethylenetetramine, lanthanum manganate and solvent to obtain mixed solution.

[0036] In the present invention, the soluble divalent nickel salt is preferably nickel nitrate, nickel chloride, nickel acetate or nickel sulfate, more preferably nickel nitrate.

[0037] In the present invention, the soluble divalent cobalt salt is preferably c...

Embodiment 1

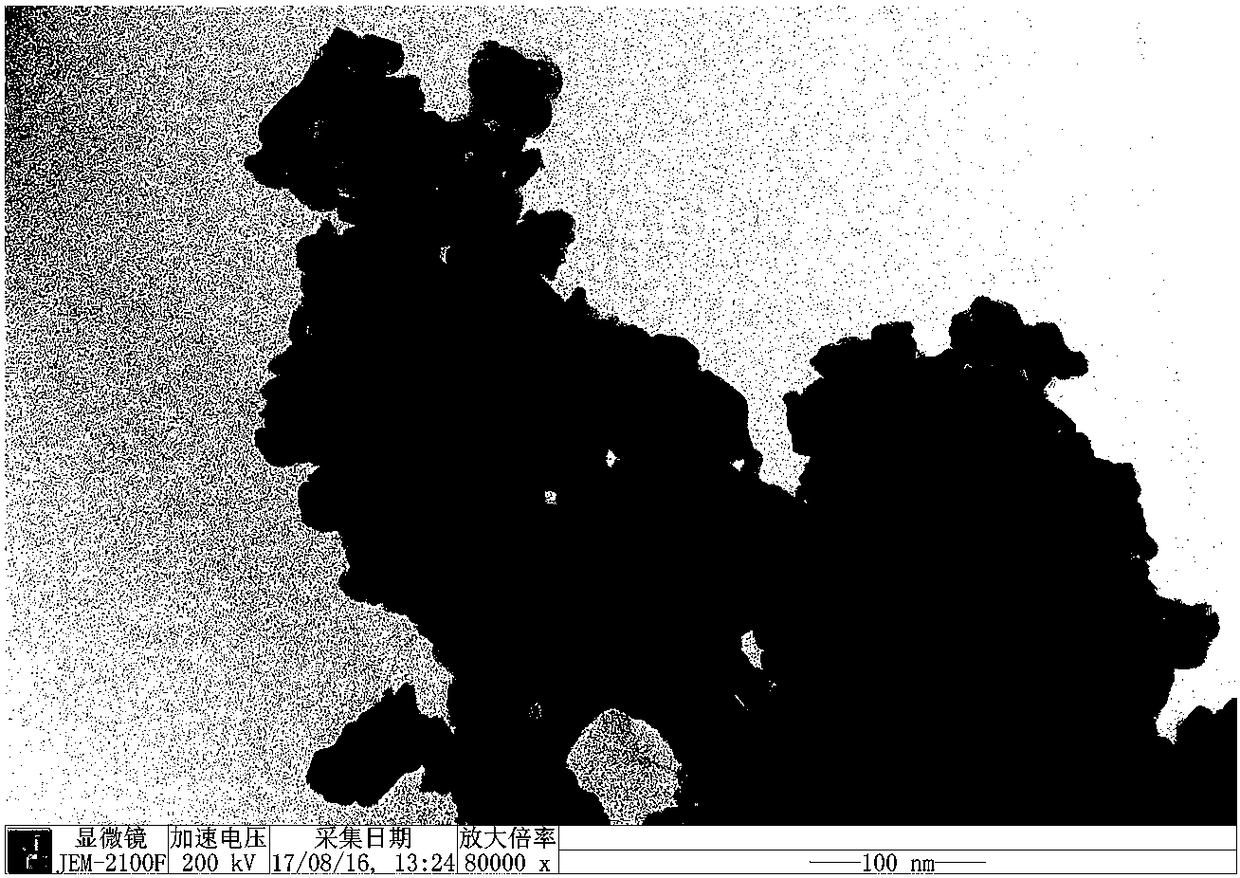

[0061] Dissolve 3.25g of lanthanum nitrate, 3.58g of manganese nitrate (50% solution) and 4.2g of citric acid (metal / citric acid molar ratio=1 / 1) in 50mL of deionized water, adjust the pH to 8 with ethylenediamine to form a solvent, 80°C constant temperature water bath until a small amount of light yellow solid is formed. After drying in a vacuum oven at 180°C for 10 hours, grinding, and annealing in a muffle furnace at 600°C for 4h (heating rate 5°C / min), the final product LaMnO was obtained after grinding 3 . figure 1 and figure 2 Respectively be the LaMnO that embodiment example 1 prepares 3 The scanning electron microscope and transmission electron microscope images of figure 1 and figure 2 It can be seen that the lanthanum manganate sample is mainly composed of irregular particles with a diameter of tens of nanometers.

Embodiment 2

[0063] (1) Disperse 290.79mg of nickel nitrate and 582.06mg of cobalt nitrate in 40mL of deionized water and 20mL of ethanol, stir at room temperature for 0.5h; add 841.14mg of hexamethylenetetramine into the above solution, stir to disperse evenly ; The LaMnO made in 100mg embodiment 1 3 The nanoparticles were dissolved in the mixed solution in step 2, and stirred for 0.5h to obtain a black mixed solution;

[0064] (2) Add the mixed liquid stirred in step (1) into a 100ml reaction kettle, move it to a constant temperature box and raise the temperature to 90°C, and keep it warm for 10h;

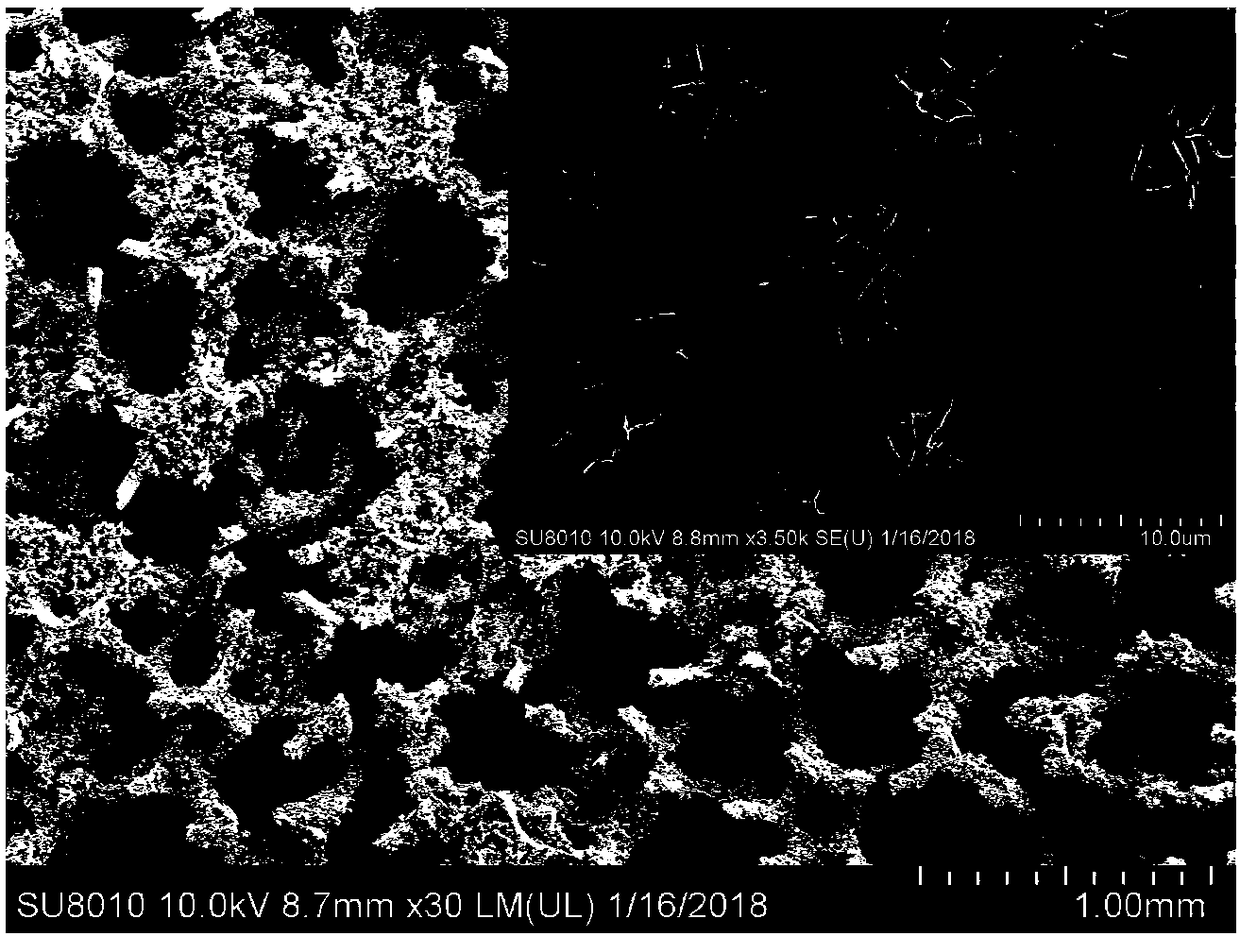

[0065] (3) Naturally cool to room temperature after the reaction is over, take out the nickel foam containing the sample, wash it three times with deionized water and three times with ethanol, and finally move it into a blast drying oven at 60°C for 12h; anneal at 300°C for 2h (heating Rate 5°C min -1 . ) to obtain LaMnO supported on nickel foam 3 @NiCo 2 o 4 Composite electrode materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com