A kind of preparation method of hydroxyethyl chitosan nanocomposite bone scaffold material

A hydroxyethyl chitosan and nano-composite technology, applied in the field of biomedical materials, can solve problems such as poor mechanical properties, and achieve low cost, simple and easy-to-operate preparation process, and good multiplication effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of biphasic calcium phosphate nanopowder: 0.4M Ca(NO 3 ) 2 .4H 2 O solution and 0.2M (NH 4 ) 2 HPO 4 The solution was added into a three-necked flask according to the calcium-phosphorus molar ratio of 1.65:1, stirred and mixed evenly, and then the pH was adjusted to 11 with 25% ammonia water to obtain a white powder precipitate. After filtering, the white powder was washed with deionized water. Then dry it at 80°C, put it into a muffle furnace for roasting, first raise the temperature to 1125°C at a rate of 10°C / min, keep it for 1 hour, then drop it to room temperature with the furnace, then take it out and grind it, and finally pass it through a 200-mesh sieve to obtain a two-phase Calcium phosphate nanopowder;

[0025] (2) prepare hydroxyethyl chitosan: get 10g chitosan and join in the 50wt% sodium hydroxide solution of 16.7g and carry out alkalization, obtain chitosan solution, described alkalization is carried out in-20 ℃ refrigerator, The alka...

Embodiment 2

[0029] The preparation process is basically the same as in Example 1, except that the mass ratio of hydroxyethyl chitosan, cellulose, and biphasic calcium phosphate nanopowder in step (2) is 2:1:1.

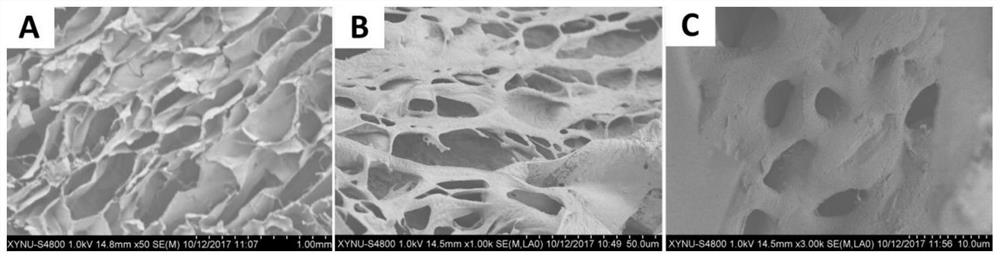

[0030] The scanning electron micrograph of the composite bone scaffold material that embodiment 2 makes is shown in figure 1 ,in, figure 1 A is the composite bone scaffold material of embodiment 1, figure 1 B is the composite bone scaffold material of Example 2.

Embodiment 3

[0032] The preparation process is basically the same as in Example 1, except that the mass ratio of hydroxyethyl chitosan, cellulose, and biphasic calcium phosphate nanopowder in step (2) is 1:1:2.

[0033] The scanning electron micrograph of the composite bone scaffold material that embodiment 3 makes is shown in figure 1 ,in, figure 1 A is the composite bone scaffold material of embodiment 1, figure 1 B is the composite bone scaffold material of embodiment 2, figure 1 C is the composite bone scaffold material of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com