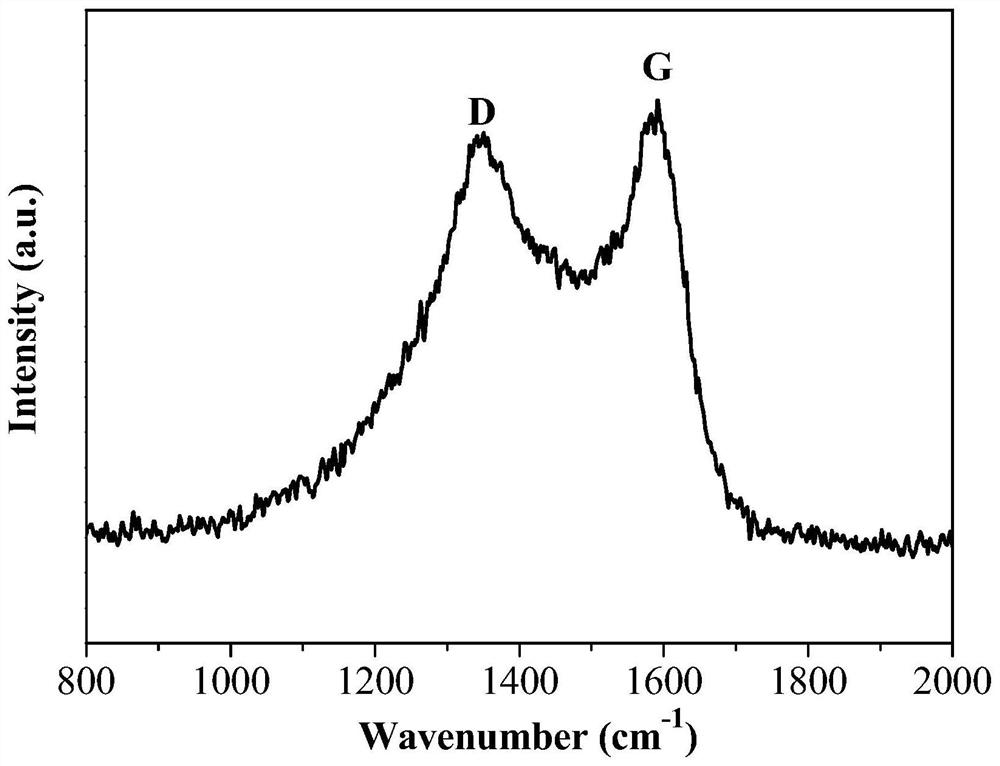

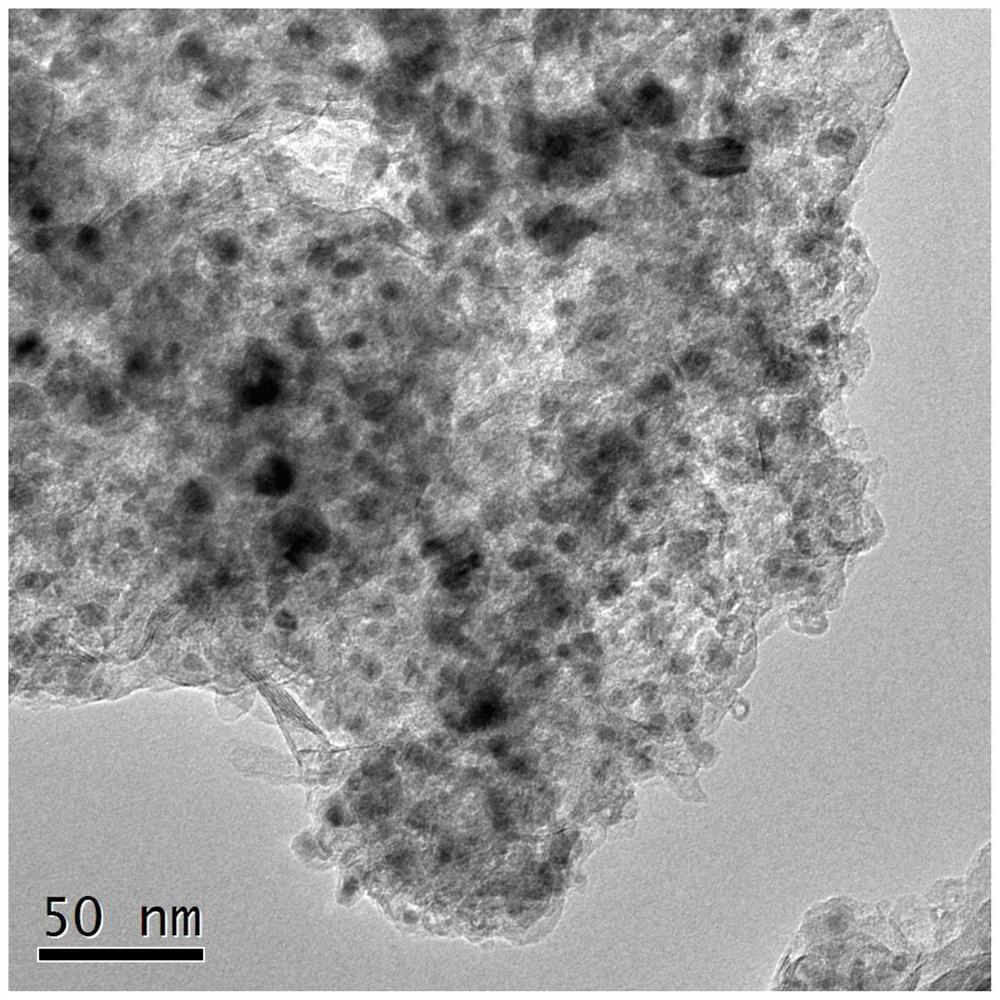

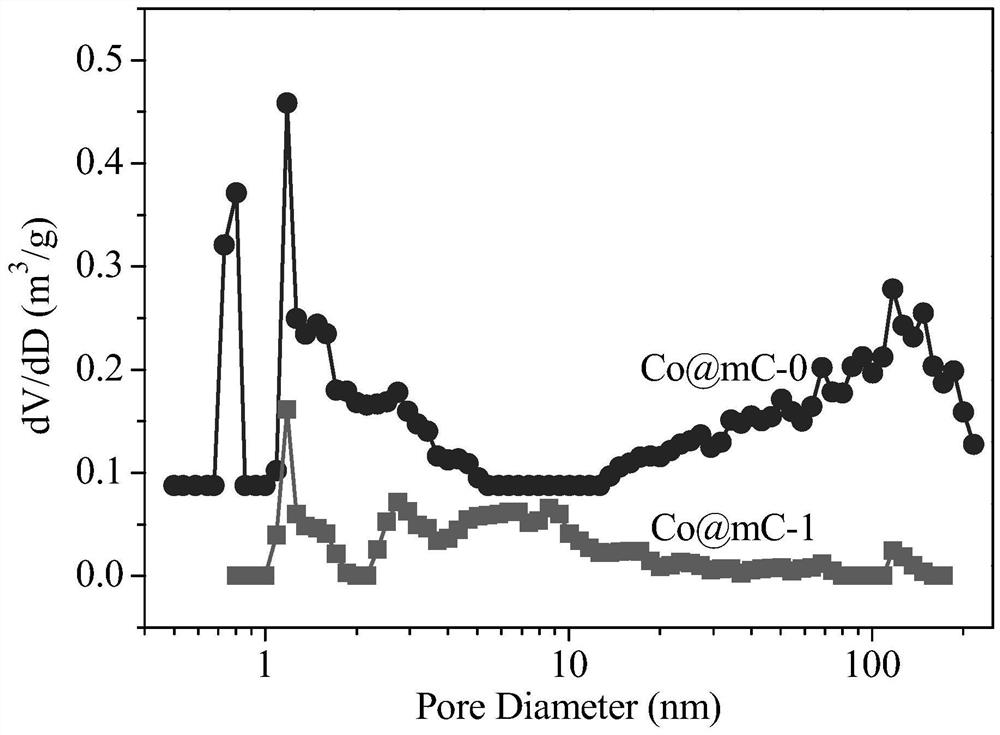

Graphite carbon wrapped nano-cobalt mesoporous composite material, its preparation method and application

A composite material and nano-cobalt technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as poor performance, unfavorable mass transfer and diffusion, etc., to achieve wide source of raw materials, mesoporous Uniform pore size distribution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of graphite carbon wrapped nano-cobalt mesoporous composite material, which comprises the following steps:

[0030] Add the cobalt nitrate aqueous solution to the 2-methylimidazole aqueous solution, mix and react, centrifuge, and dry once to obtain a solid; preferably, before adding the cobalt nitrate aqueous solution to the 2-methylimidazole aqueous solution, mix nano-state silicon The imidazole aqueous solution is mixed and stirred evenly; preferably, the mass ratio of silicon dioxide and 2-methylimidazole is 0-5:5-25; preferably, the mass fraction of 2-methylimidazole aqueous solution is 5%-25%; preferably Yes, the mixing and stirring time is 2-4 hours, and the mixing and stirring temperature is 25-35°C; preferably, the mass ratio of cobalt nitrate to 2-methylimidazole is 1-5:10-50; preferably, the cobalt nitrate aqueous solution The mass fraction is 3% to 18%; preferably, the mixing reaction time is 5 to 8 hours; the mixing reaction temperature ...

Embodiment 1

[0036] The embodiment of the present invention provides a graphite carbon-wrapped nano-cobalt mesoporous composite material, the preparation method of which is as follows:

[0037] S11. Weigh 5.5 g of 2-methylimidazole and dissolve it in 20 g of deionized water, stir and dissolve at 25° C. to obtain a 2-methylimidazole solution;

[0038]S12. Weigh 0.5 g of cobalt nitrate salt and dissolve it in 3 g of deionized water. After ultrasonic dispersion, add it to the above-mentioned 2-methylimidazole solution and react for 6 hours, then use water twice and methanol once to centrifuge at 8000 rpm, place Vacuum drying at 80°C for 24 hours gave a blue-purple solid;

[0039] S13. After pulverizing the blue-purple solid, place it in a tube furnace and calcinate at 700° C. for 4 hours in a nitrogen (40 mL / min) atmosphere to obtain a black powder;

[0040] S14. Disperse the black powder in 60mL of 1mol / L sodium hydroxide solution and stir, heat up to 60°C and react for 24h, wash with deion...

Embodiment 2

[0042] The embodiment of the present invention provides a graphite carbon-wrapped nano-cobalt mesoporous composite material, the preparation method of which is as follows:

[0043] S21. Weighing 5.5 g of 2-methylimidazole and dissolving it in 20 g of deionized water, stirring and dissolving at 25° C., adding 0.5 g of nano-colloidal silica, and continuously stirring and dispersing for 2 hours to obtain a mixed solution;

[0044] S22. Weigh 0.5 g of cobalt nitrate salt and dissolve it in 3 g of deionized water. After ultrasonic dispersion, add it to the above mixed solution for 6 hours of reaction, use water twice and methanol once to centrifuge at 8000 rpm, and place in a vacuum at 80 ° C. Dry for 24h to obtain a blue-purple solid;

[0045] S23. After pulverizing the blue-purple solid, place it in a tube furnace and calcinate at 700° C. for 4 hours in a nitrogen (40 mL / min) atmosphere to obtain a black powder;

[0046] S24. Disperse the black powder in 60mL of 1mol / L sodium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com