Preparation method of sodium fluoride double-ion battery and its application in electrochemical defluorination

A dual-ion, sodium fluoride technology, applied in electrochemical generators, chemical instruments and methods, secondary batteries, etc., can solve the problems of poor fluoride ion removal ability and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

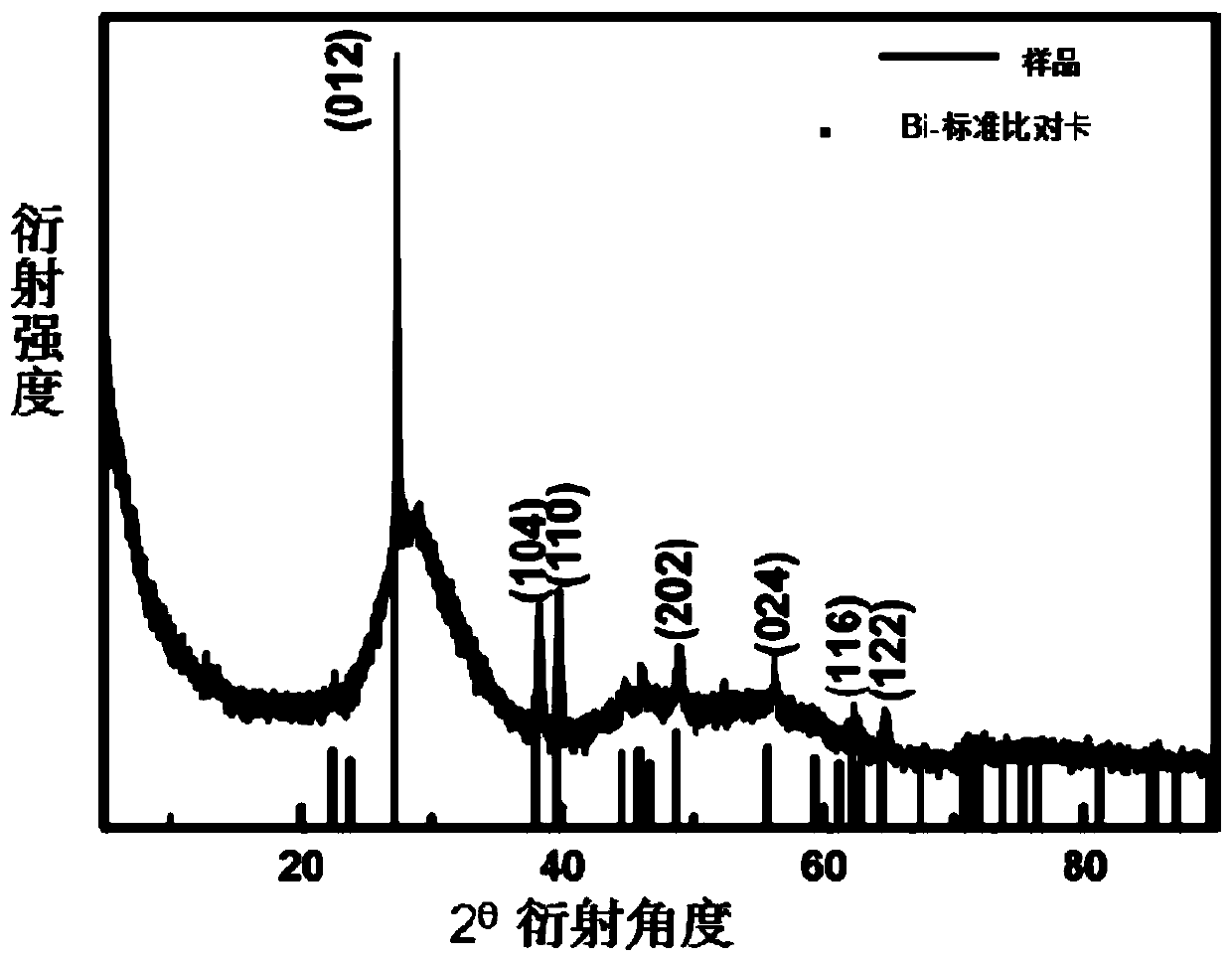

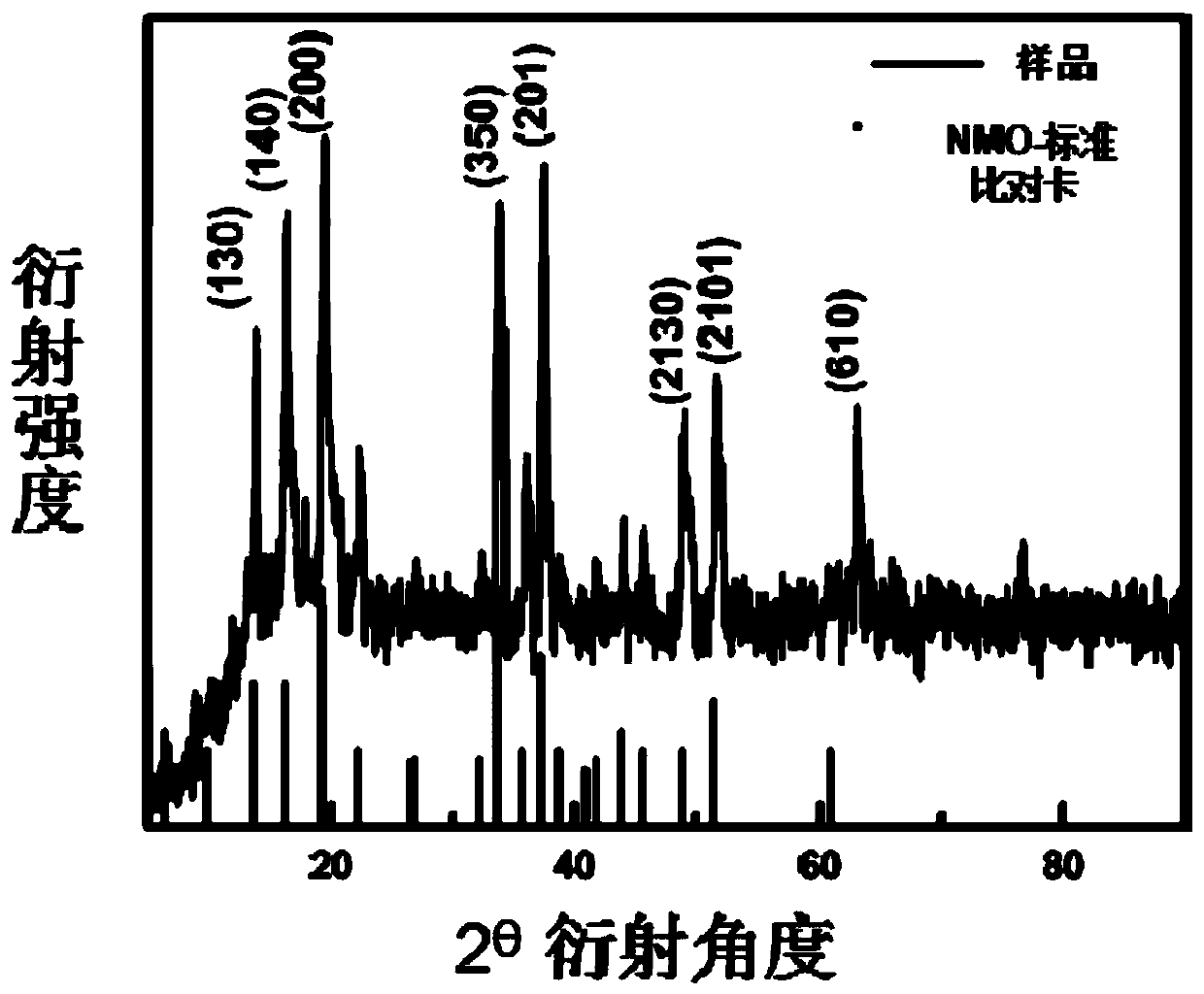

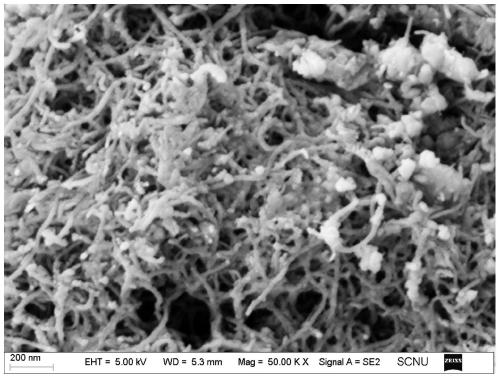

[0098] (1) The preparation of the nano-bismuth negative electrode material covered by carboxylated carbon nanotubes, the specific steps are as follows:

[0099] (1) Put 1.5g of carbon nanotubes in a round-bottomed flask, and add 100ml of a mixed solution of 98% concentrated sulfuric acid and 68% concentrated nitric acid in a volume ratio of 1:2 to the round bottom In the flask, carry out ultrasonic dispersion with a power of 300W for 10min; then carry out magnetic stirring with a rotating speed of 400r / min for 0.5h; Filtration), and washed with deionized water for many times until the pH was neutral to obtain filter cake A;

[0100] (2) drying the filter cake A obtained in step (1) at 60° C. for 1 h under vacuum and then grinding to obtain powder B;

[0101] (3) place powder B obtained in step (2) in a round-bottomed flask, add 120ml volume ratio: 1:2.5 mass fraction of 98% concentrated sulfuric acid and mass fraction of 36% hydrogen peroxide mixed solution, carry out 15min ...

Embodiment 2

[0118] (1) The preparation of the nano-bismuth negative electrode material coated with carboxylated carbon nanotubes, the specific steps are as follows:

[0119] (1) 2.5g of carbon nanotubes are placed in a round-bottomed flask, and 100ml of a volume ratio of 1:3 is a mixed solution of concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 68%. In the flask, perform ultrasonic dispersion with a power of 300W for 10min; then perform magnetic stirring at a speed of 1500r / min for 1h; dilute with a large amount (1000ml) of deionized water, filter under reduced pressure with 0.22μm filter paper after cooling, and wash with deionized water Repeatedly until the pH is neutral to obtain filter cake A;

[0120] (2) The filter cake A obtained in step (1) was vacuum-dried at 100°C for 2 hours, and then ground to obtain powder B;

[0121] (3) The powder B obtained in step (2) is placed in a round-bottomed flask, and 150ml of volume rati...

Embodiment 3

[0138] (1) The preparation of the nano-bismuth negative electrode material coated with carboxylated carbon nanotubes, the specific steps are as follows:

[0139] (1) 2.8g of carbon nanotubes are placed in a round bottom flask, and 200ml of a volume ratio of 1:4 is a mixed solution of concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 68%. In the flask, carry out ultrasonic dispersion with a power of 300W for 40 minutes; then carry out magnetic stirring at a speed of 2000r / min for 2 hours; dilute with a large amount (1000ml) of deionized water, filter under reduced pressure with 0.22μm filter paper after cooling, and wash with deionized water Repeatedly until the pH is neutral to obtain filter cake A;

[0140] (2) The filter cake A obtained in step (1) was vacuum-dried at 100°C for 3 hours, and then ground to obtain powder B;

[0141] (3) Place the powder B obtained in step (2) in a round-bottomed flask, add 150ml volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com