Method for preparing high-stability nanometer black phosphorus/three-dimensional graphene composite materials

A composite material and graphene technology, applied in the field of composite materials, can solve the problems of high energy consumption, complex plasma sintering process, unfavorable industrial production, etc., and achieve large active area, high conductivity and ion transmission performance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

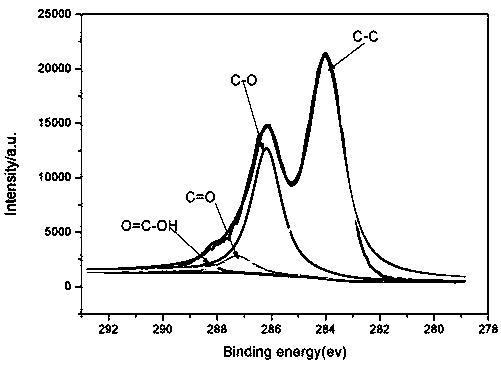

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation method of highly stable nano black phosphorus / three-dimensional graphene composite material, concrete steps are as follows:

[0025] (1) Under the condition of a temperature of 15°C and an inert gas (argon) atmosphere, the nano-black phosphorus dispersion (the nano-black phosphorus dispersion is nano-black phosphorene / water dispersion) and the graphene oxide dispersion (graphite oxide ene dispersion is graphene oxide / water dispersion) and mixed with ultrasonic treatment to obtain dispersion A; wherein the concentration of nano-black phosphorus dispersion (nano-black phosphorene / water dispersion) is 1 mg / mL, and the graphene oxide dispersion The concentration of (graphene oxide / water dispersion) is 4mg / mL, the mass ratio of nano black phosphorus to graphene oxide is 1:4; ultrasonic treatment is ultrasonic pretreatment with ultrasonic cell washer, and the power of ultrasonic cell washer 200W, the processing time of the ultrasonic cell c...

Embodiment 2

[0032] Embodiment 2: a kind of preparation method of highly stable nano black phosphorus / three-dimensional graphene composite material, concrete steps are as follows:

[0033] (1) Under the condition of a temperature of 25°C and an inert gas (nitrogen) atmosphere, the nano-black phosphorus dispersion (the nano-black phosphorus dispersion is a black phosphorus quantum dot / N-methylpyrrolidone dispersion) and the graphene oxide dispersion (The graphene oxide dispersion is graphene oxide / N-methylpyrrolidone dispersion) mixed and ultrasonically treated to obtain dispersion A; wherein the nano black phosphorus dispersion (black phosphorus quantum dots / N-methylpyrrolidone dispersion) The concentration is 1mg / mL, the concentration of graphene oxide dispersion (graphene oxide / N-methylpyrrolidone dispersion) is 4mg / mL, the mass ratio of nano black phosphorus to graphene oxide is 1:1; Ultrasonic pretreatment is performed by the cell pulverizer, the cell pulverizer is 1500W, and the ultra...

Embodiment 3

[0036] Embodiment 3: a kind of preparation method of highly stable nano black phosphorus / three-dimensional graphene composite material, concrete steps are as follows:

[0037](1) Under the condition of a temperature of 25°C and an inert gas (nitrogen) atmosphere, the nano-black phosphorus dispersion (the nano-black phosphorus dispersion is a black phosphorus quantum dot / 1-butyl-trimethylimidazolium dicyanamide dispersion ) mixed with graphene oxide dispersion (graphene oxide dispersion is graphene oxide 1-butyl-trimethylimidazolium dicyanamide dispersion), and ultrasonically treated to obtain dispersion A; wherein nano-black phosphorus dispersion (black Phosphorus quantum dots / 1-butyl-trimethylimidazolium dicyanamide dispersion) at a concentration of 1 mg / mL, graphene oxide dispersion (graphene oxide / 1-butyl-trimethylimidazolium dicyanamide dispersion ) concentration is 4mg / mL, the mass ratio of nanometer black phosphorus to graphene oxide is 1:3; the ultrasonic treatment is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com