A kind of preparation method of perovskite film with microtube array structure

An array structure and perovskite technology, applied in the field of light-absorbing materials for solar cells, can solve problems such as good stability, poor environmental protection, and not easy to deliquescence, etc., to achieve improved orientation and uniformity, life expectancy, movement rate, and crystallization rate delayed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

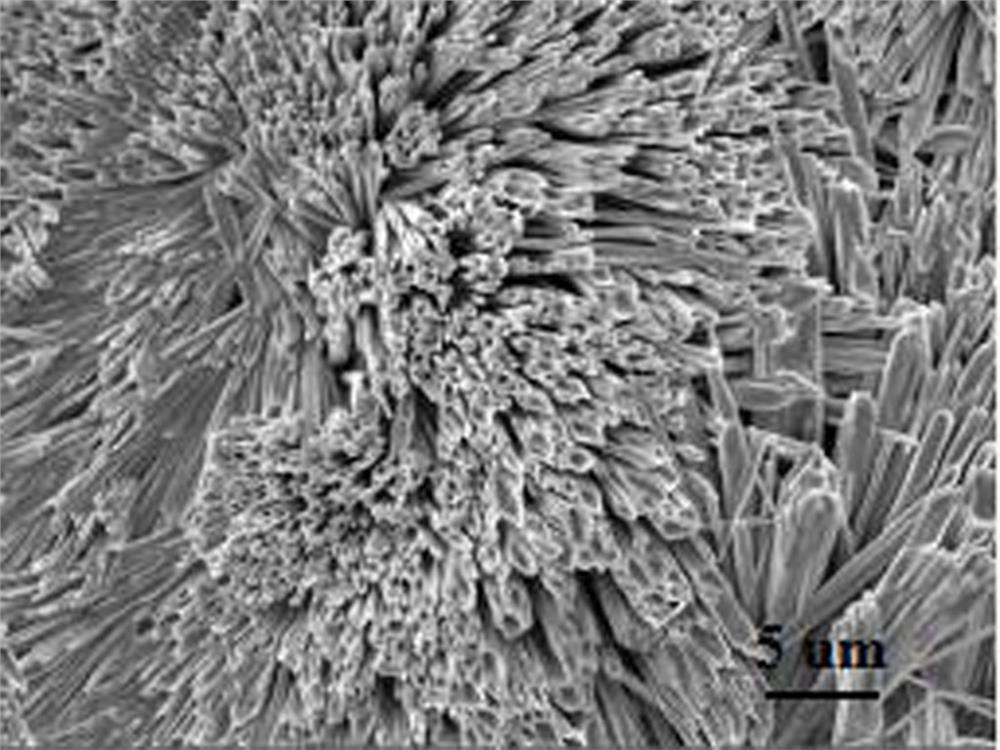

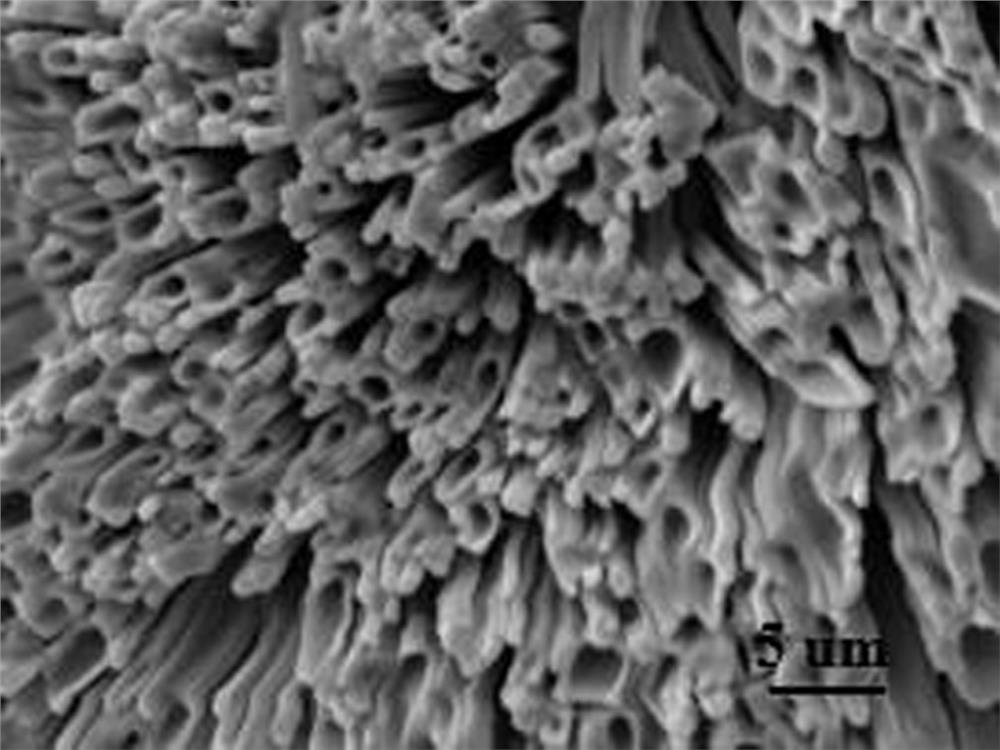

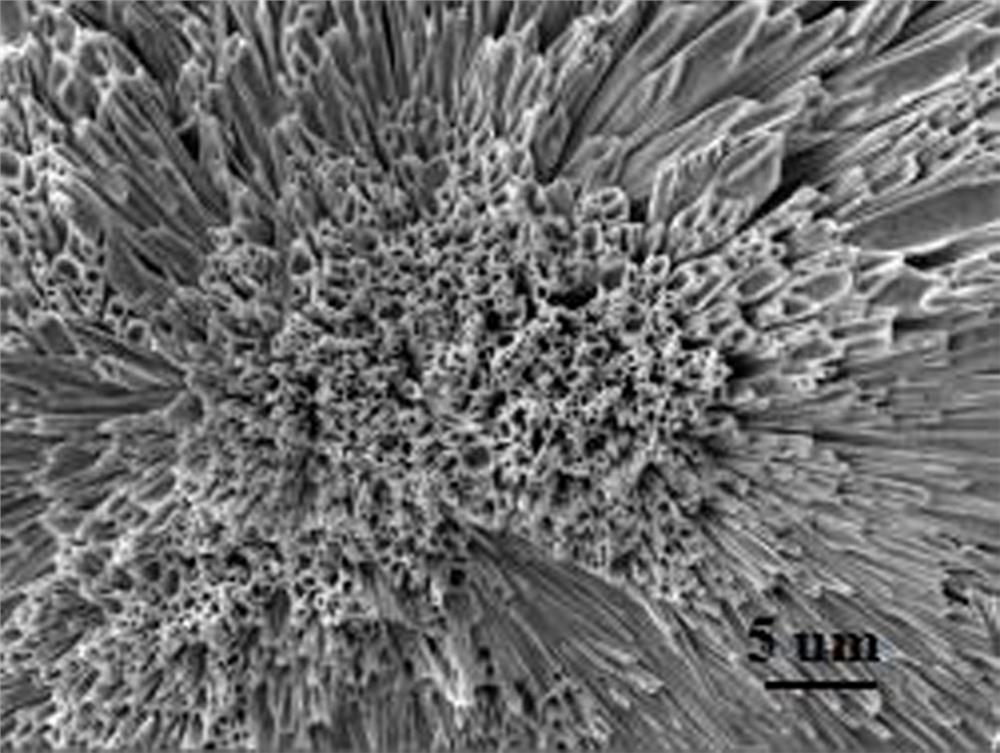

Image

Examples

preparation example Construction

[0032] A method for preparing a perovskite film with a microtube array structure, comprising the following steps:

[0033] (1) Clean the FTO transparent conductive glass with acetone, alcohol, and deionized water in sequence, ultrasonically clean it for 10-15 minutes each time, then dry it with a nitrogen gun, and then put the FTO glass substrate into an ozone machine for ozone treatment for 10-15 minutes ;

[0034] (2)CH 3 NH 3 PB 3-x Cl x Preparation of precursor solution: CH 3 NH 3 I and PbCl 2 Mix and dissolve in N,N-dimethylformamide solvent at a molar ratio of 1:1 to 3:1, where the ratio between solvent and mixed solute is 0.1

[0035] ~0.3mol / l, produce CH 3 NH 3 PB 3-x Cl x Precursor solution, the solution is oscillated in an ultrasonic cleaner for 8-14 hours, and the ultrasonic cleaner is heated to 40°C-60°C to obtain fully reacted CH 3 NH 3 PB 3-x Cl x Precursor solution.

[0036] (3) CH doped with deionized water 3 NH 3 PB 3-x Cl x Film preparati...

Embodiment 1

[0040] A method for preparing a perovskite film with a microtube array structure, comprising the following steps:

[0041] (1) Cleaning and ozone treatment of FTO glass: After scrubbing the FTO transparent conductive glass with detergent, then ultrasonically clean it with acetone, deionized water, alcohol, and deionized water for 10 minutes, and then dry it with a nitrogen gun. Then put the FTO substrate into an ozone machine and carry out ozone treatment for 15 minutes to obtain a conductive glass substrate for subsequent use;

[0042] (2)CH 3 NH 3 PB 3-x Cl x Preparation of precursor solution: CH 3 NH 3 I and PbCl 2 Mix and dissolve in N,N-dimethylformamide solvent at a molar ratio of 1:1 to obtain CH 3 NH 3 PB 3-x Cl x Precursor solution, the solution was oscillated in an ultrasonic cleaner for 8 hours, and the ultrasonic cleaner was heated to 60°C to obtain CH 3 NH 3 PB 3-x Cl x Precursor solution, spare;

[0043] (3) CH doped with deionized water 3 NH 3 P...

Embodiment 2

[0045] A method for preparing a perovskite film with a microtube array structure, comprising the following steps:

[0046] (1) Cleaning and ozone treatment of FTO glass: After scrubbing the FTO transparent conductive glass with detergent, then ultrasonically clean it with acetone, deionized water, alcohol, and deionized water for 12 minutes, and then dry it with a nitrogen gun. Then put the FTO substrate into an ozone machine and carry out ozone treatment for 14min to obtain a conductive glass substrate for subsequent use;

[0047] (2)CH 3 NH 3 PB 3-x Cl x Preparation of precursor solution: CH 3 NH 3 I and PbCl 2 Mix and dissolve in N,N-dimethylformamide solvent at a molar ratio of 2:1 to obtain CH 3 NH 3 PB 3-x Cl x Precursor solution, the solution was oscillated in an ultrasonic cleaner for 10 h, and the ultrasonic cleaner was heated to 50 °C to obtain CH 3 NH 3 PB 3-x Cl x Precursor solution, spare;

[0048] (3) CH doped with deionized water 3 NH 3 PB 3-x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com