Preparation method for silicon-phosphorus-aluminum molecular sieve

A silicon-phosphorus-aluminum molecular sieve and aluminum source technology, applied in the direction of molecular sieves and alkali-exchanged phosphates, molecular sieve characteristic silicon-aluminophosphates, etc., can solve the problems of low catalytic activity, large diffusion resistance, low mesopore content, etc., and achieve reduction Diffusion resistance, good hydrothermal stability, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

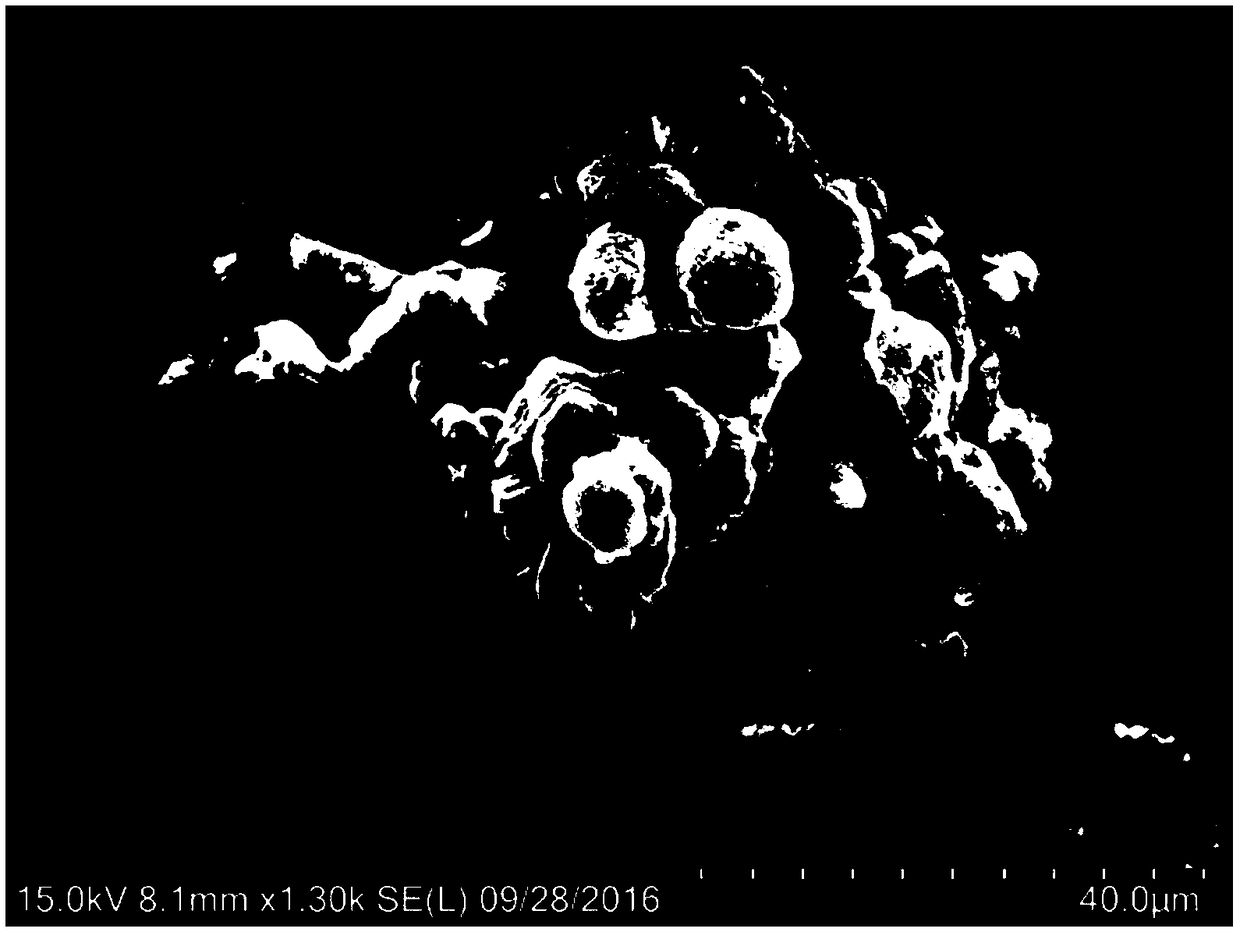

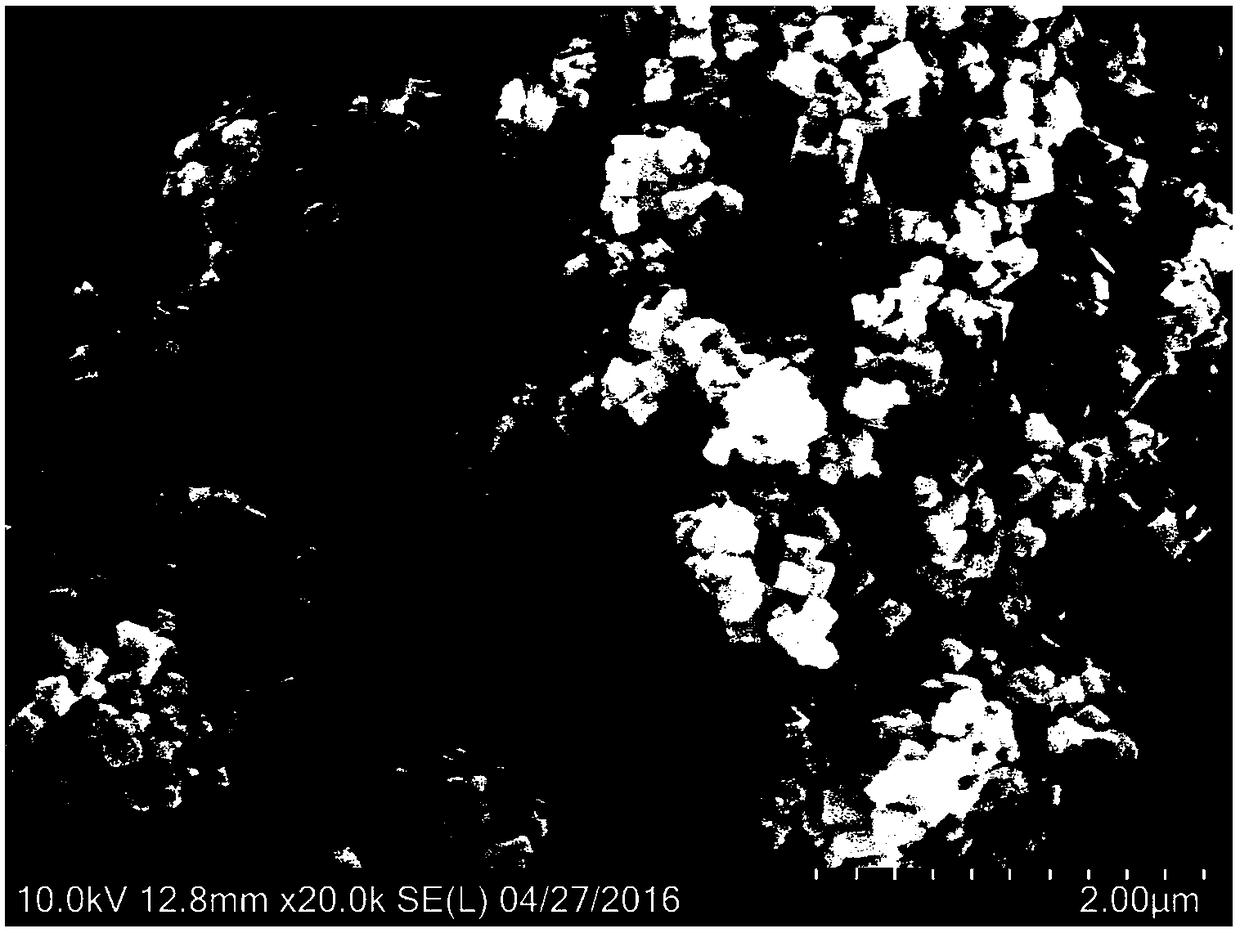

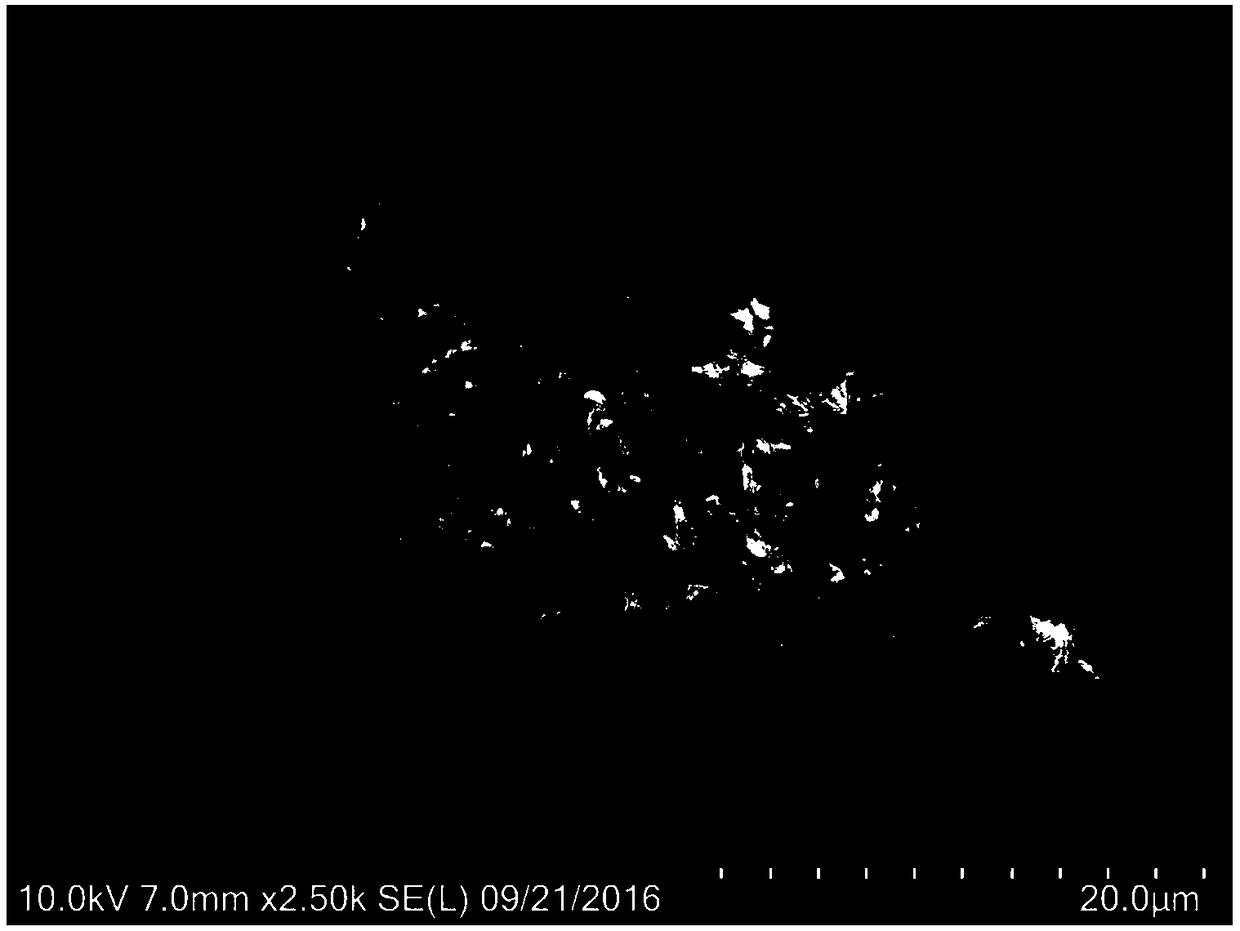

Image

Examples

Embodiment 1

[0038] a) Fully mix aluminum isopropoxide, water, di-n-propylamine, concentrated phosphoric acid, and acidic silica sol according to the molar ratio of 1:70:0.4:1:0.8, stir evenly, adjust the pH value to 4.5 to obtain gel A, Put it into a crystallization kettle and crystallize for 12 hours under autogenous pressure at 160°C;

[0039] b) cetyltrimethylammonium bromide and (ethanol: water = 3:1 mass ratio) were mixed and stirred at a molar ratio of 0.15:1 to obtain solution B;

[0040] c) Stir the crystallized gel A in step a) fully and then slowly add solution B, wherein the molar ratio of the aluminum source of gel A to the solvent of solution B is 1:0.8, and then adjust the pH value to 4.5 with a template to obtain a gel. Glue C;

[0041] d) The gel C obtained in step c) was dehydrated by rotary evaporation at 120°C, and after being completely dehydrated, it was quickly placed in an oven at 220°C to dry to obtain a precursor;

[0042] e) Grinding and crushing the precursor ...

Embodiment 2

[0046] a) Fully mix pseudo-boehmite, water, tetraethylammonium hydroxide, concentrated phosphoric acid, and tetraethylorthosilicate at a molar ratio of 1:50:4:1:0.4, stir evenly, and adjust the pH value Gel A was obtained at 7.0, put into a crystallization kettle and crystallized under autogenous pressure at 180°C for 8 hours;

[0047] b) Chitosan and water are mixed and stirred at a molar ratio of 0.2:1 to obtain solution B;

[0048] c) Fully stir the crystallized gel A in step a) and then slowly add solution B, wherein the molar ratio of the aluminum source of gel A to the solvent of solution B is 1:1.5, and then adjust the pH value to 6.5 with a template agent to obtain Gel C;

[0049]d) The gel C obtained in step c) was dehydrated by rotary evaporation at 120°C, and after being completely dehydrated, it was quickly placed in an oven at 260°C to dry to obtain a precursor;

[0050] e) Grinding and crushing the precursor of step d), placing it in the upper part of the react...

Embodiment 3

[0054] a) Fully mix aluminum isopropoxide, water, morpholine, phosphorous acid, and acidic silica sol according to the molar ratio of 1:30:2:0.8:0.1, stir evenly, adjust the pH value to 3.5 to obtain gel A, pack Put into the crystallization kettle and crystallize for 45h under autogenous pressure at 120°C;

[0055] b) Mix and stir sucrose and dimethyl ether at a molar ratio of 0.05:1 to obtain solution A;

[0056] c) After fully stirring the gel A crystallized in step a), slowly add solution A, wherein the molar ratio of the gel A and the aluminum source in the solution A to the solvent is 1:1, and then adjust the pH value with a templating agent 3.5 Obtain gel B;

[0057] d) The gel B obtained in step c) was dehydrated by rotary evaporation at 80°C, and after being completely dehydrated, it was quickly placed in an oven at 160°C to dry to obtain a precursor;

[0058] e) Grinding and crushing the precursor of step d), placing it in the upper part of the reaction kettle, putt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com