Zinc humic acid long-acting compound fertilizer and preparation method thereof

A technology of zinc humic acid and compound fertilizer, which is applied in the direction of urea compound fertilizer, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problems such as unable to solve the target, and achieve improvement of soil fertility, stability and utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A zinc humic acid long-acting compound fertilizer, the composition of raw materials in parts by weight is as follows: urea 185-198, monoammonium phosphate 380-398, potassium chloride 255-275, potassium sulfate 70-85, ammonium sulfate 0-45, zinc humic acid Acid 10-20, potassium humate 10-18, stabilizer 0.5-1.5, filler 20-60.

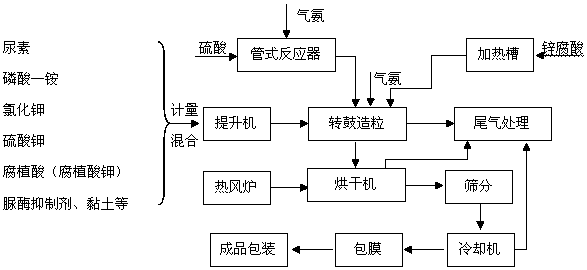

[0020] The preparation method of the zinc humic acid long-acting compound fertilizer is that after metering urea, monoammonium phosphate, potassium chloride, potassium sulfate, potassium humate, stabilizer and filler, they are sent into the drum making machine by a mixing hoist. The granulator forms a material bed; concentrated sulfuric acid and gaseous ammonia react in the tubular reactor to generate ammonium sulfate mixed slurry, which is sprayed on the material bed of the drum granulator together with the heated zinc humic acid, and melted at high temperature Under the action, they are bonded to each other to form granules, and at the same time,...

Embodiment 2

[0027] As a preference of Example 1, the stabilizer is a urease inhibitor.

[0028] And, for ammonium sulfate, we have given two formulas, a zinc humic acid long-acting compound fertilizer, the composition of raw materials is as follows: urea 185-198, monoammonium phosphate 380-398, potassium chloride 255-275, sulfuric acid Potassium 70-85, zinc humic acid 10-20, potassium humate 10-18, stabilizer 0.5-1.5, filler 50-60. Ammonium sulfate is not added thereto.

[0029] There is also a zinc humic acid long-acting compound fertilizer. The raw materials are composed in parts by weight as follows: urea 185-198, monoammonium phosphate 380-398, potassium chloride 255-275, potassium sulfate 70-85, ammonium sulfate 35-45, zinc humic acid Acid 10-20, potassium humate 10-18, stabilizer 0.5-1.5, filler 20-30. Add ammonium sulfate to it.

[0030] The filler is clay.

Embodiment 3

[0032] As a preferred embodiment of Example 1, the heated zinc humic acid refers to: heating the zinc humic acid through a heating tank, the heating temperature is 60° C., and the heating time is 15 minutes.

[0033] The parameter settings in the drum granulator are: steam pressure 2-3.5kg, tubular reactor temperature 90-130°C, granulated material outlet temperature 60-65°C, granulated material granulation rate 75-90%, The pH value of the granulation material is 5.8-7.0, and the moisture content of the material at the outlet of the granulator is 2.0-3.0%.

[0034] Said introducing a certain amount of ammonia refers to: injecting 30-35% of ammonia.

[0035] The parameter settings of the dryer are: first dryer head 100-300°C, first dryer tail 50-70°C; second dryer head 170-200°C, second dryer tail 50-60°C.

[0036] In the above examples, the content of humic acid in zinc humic acid is 8%, and the content of humic acid in the product should not be less than 10kg / t; considering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com