A kind of preparation method of triblock nonionic polyurethane fluorine-containing short-chain surfactant

A surfactant, non-ionic technology, applied in the field of preparation of surfactants, can solve the problem that triblock non-ionic fluorine-containing short-chain surfactants have not been reported, achieve excellent self-assembly performance, can be designed Strong, easy-to-get effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

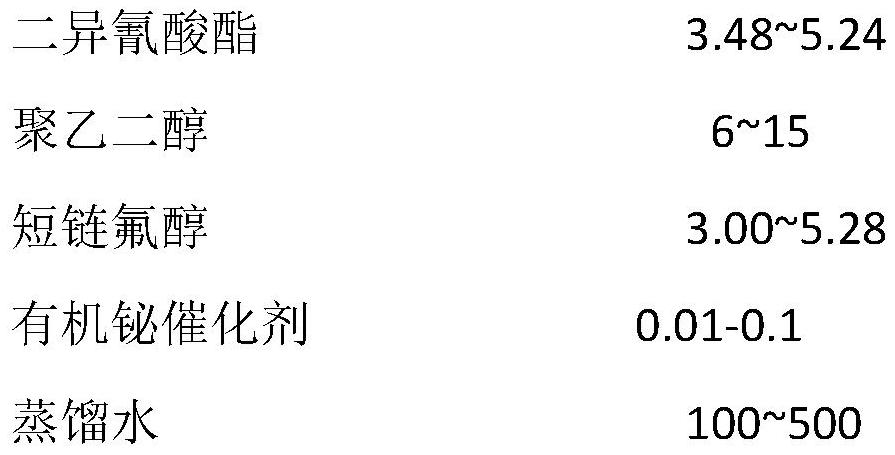

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Under the conditions of 120°C and a vacuum of 0.09MPa, polyethylene glycol was subjected to vacuum distillation for 6 hours to remove water; the activated 3A molecular sieve was added to hexafluoroisopropanol, sealed and placed overnight, Remove moisture; dry the three-necked bottle, agitator, and feeding tube at 100°C for 2 hours, take it out and place it in a desiccator to cool; Polyethylene glycol and 4.44g of isophorone diisocyanate, add 10μL organic bismuth catalyst, stir in a constant temperature water bath at 80°C, and react for 5 hours; cool down to 55°C, then add 3.36g of hexafluoroisopropanol, continue in the water bath Stir in medium and react for 10 hours to obtain triblock nonionic polyurethane fluorine-containing short-chain surfactant.

Embodiment 2

[0028] Example 2: Distill polyethylene glycol under reduced pressure for 6 hours at 120°C and a vacuum of 0.09 MPa to remove water; add activated 3A molecular sieves to 2,2,3,3,3-5 In fluoro-1-propanol, place it in a sealed place overnight to remove moisture; dry the three-necked bottle, agitator, and feeding tube at 100°C for 2 hours, take it out and place it in a desiccator to cool; Add 10.0 g of polyethylene glycol with a number average molecular weight of 1000 and 4.44 g of isophorone diisocyanate into the bottle, add 10 μL of organic bismuth catalyst, stir in a constant temperature water bath at 80°C, and react for 5 hours; cool down to 75°C, and then add 3.0 g of 2,2,3,3,3-pentafluoro-1-propanol was continuously stirred in a water bath and reacted for 8 hours to obtain a triblock nonionic polyurethane fluorinated short-chain surfactant.

Embodiment 3

[0029] Example 3: Distill polyethylene glycol under reduced pressure for 6 hours at 120°C and a vacuum of 0.09 MPa to remove water; add activated 3A molecular sieves to 1H, 1H, 2H, 2H-perfluorohexyl -1-alcohol, sealed overnight to remove moisture; dry the three-necked bottle, agitator, and feeding tube at 100°C for 2 hours, take it out and place it in a desiccator to cool; put it in a three-necked bottle with agitator and thermometer Add 10.0 g of polyethylene glycol with a number average molecular weight of 1000 and 4.44 g of isophorone diisocyanate, add 10 μL of organic bismuth catalyst, stir in a constant temperature water bath at 100°C, and react for 5 hours; cool down to 80°C, and then add 5.28g 1H, 1H, 2H, 2H-perfluorohexan-1-ol, continue to stir in a water bath, and react for 8 hours to obtain a three-block nonionic polyurethane fluorinated short-chain surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com