Beta-cyclodextrin polymer and preparation method thereof and application method of beta-cyclodextrin polymer in treatment of anionic dye wastewater

A cyclodextrin polymer, anionic dye technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of low surface area and poor adsorption performance, and achieve high specific surface area, adsorption High efficiency, simple and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

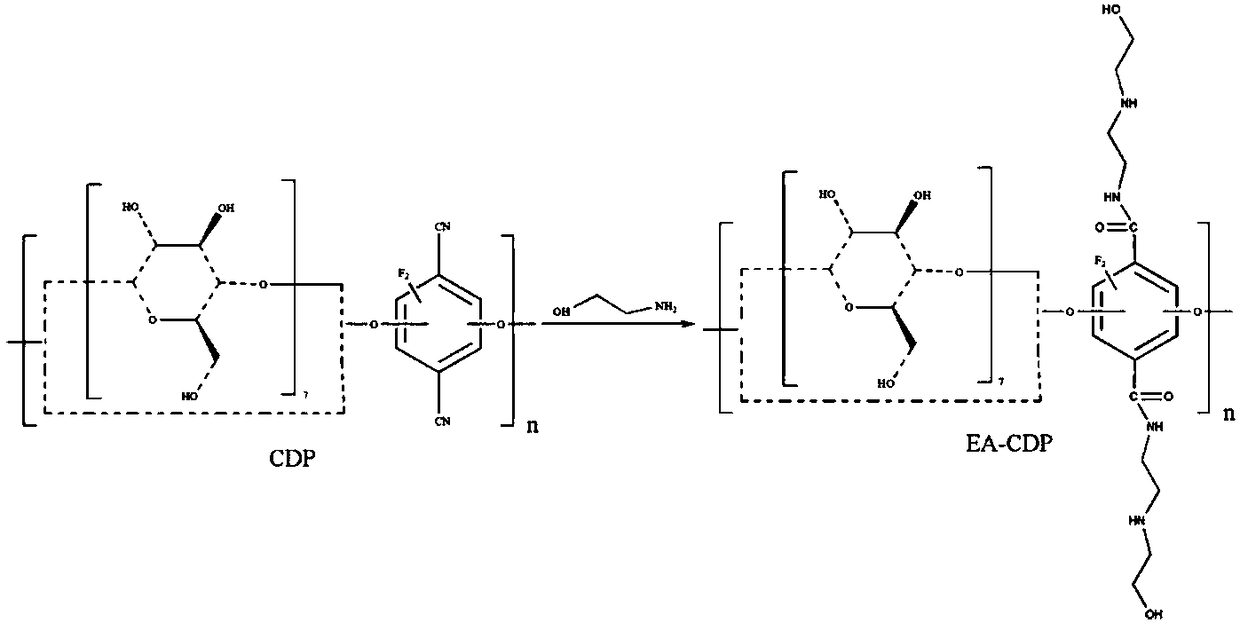

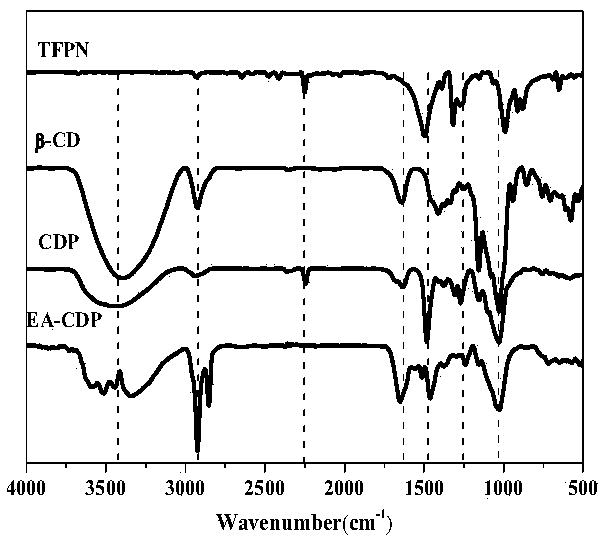

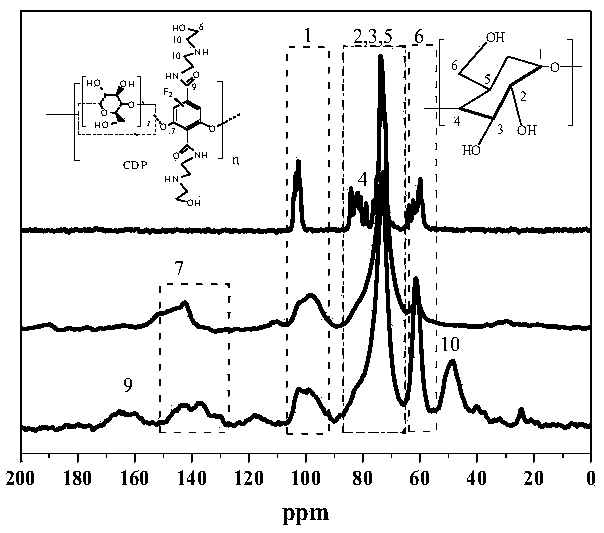

[0034] Embodiment 1, preparation β-cyclodextrin polymer (EA-CDP)

[0035] 0.962g β-cyclodextrin, 0.5g cross-linking agent tetrafluoroterephthalonitrile and 1.23g basic salt compound K 2 CO 3 Add to 27ml tetrahydrofuran (THF) and 3ml N,N-dimethylformamide (DMF) mixed solvent (V THF :V DMF =9), nitrogen flow for 5 minutes, after 48 hours of polymerization at 85°C, with 1mol / L hydrochloric acid washing the solid on the filter paper, remove residual K 2 CO 3 , until CO 2 After the release is complete, wash the obtained solid with 20ml of deionized water, 20ml of tetrahydrofuran, and 20ml of dichloromethane in sequence, then freeze-dry the solid in a high-vacuum liquid nitrogen bath for 10-20 minutes, and then vacuum-dry it at room temperature for 2-3 days to obtain The β-cyclodextrin polymer CDP after the first step of substitution reaction. Take 230 mg of CDP prepared in the above experiment, inject 20 mL of EA in a nitrogen atmosphere, and stir for 48 hours at a reaction t...

Embodiment 2

[0036] Embodiment 2, EA-CDP adsorption methyl orange experiment

[0037] Mix 10 mg of the β-cyclodextrin polymer EA-CDP obtained in Example 1 with 10 ml of a methyl orange solution with an initial concentration of 30 mg / l, and place it in a water bath constant temperature shaker at 30 ° C at 170 r min -1 The speed is oscillated for 30 minutes. After shaking, the solid and the solution were separated by suction filtration with 0.2 μm polytetrafluoroethylene filter paper. Measure the residual concentration of methyl orange in the sample by UV-vis ultraviolet-visible spectrometry (measurement wavelength is the absorbance A at 464nm place), can remove methylene blue in water and reach more than 95% within 2 hours. The β-cyclodextrin complex can be regenerated by immersing the ultrasonic β-cyclodextrin complex in ethanol, and the experiment cycle is 5 times, and the polymer has no performance loss and is small.

Embodiment 3

[0038] Embodiment 3, EA-CDP adsorption Congo red experiment

[0039] Mix 3 mg of the β-cyclodextrin polymer EA-CDP obtained in Example 1 with 10 ml of the Congo red solution with an initial concentration of 30 mg / l, and place it in a water bath constant temperature shaker at 30 ° C at 170 r min -1 The speed is oscillated for 30 minutes. After shaking, the solid and the solution were separated by suction filtration with 0.2 μm polytetrafluoroethylene filter paper. Measure the residual concentration of Congo red in the sample by UV-vis ultraviolet-visible spectrometry (measurement wavelength is the absorbance A at 497nm place), can remove Congo red in water and reach more than 95% within 2 hours. The β-cyclodextrin complex can be regenerated by immersing the ultrasonic β-cyclodextrin complex in ethanol, and the experiment cycle is 5 times, and the polymer has no performance loss and is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com