Waterproof flame-retardant wheat straw board preparation method

A wheat straw board, wheat straw technology, applied in the preparation of animal glue or gelatin, manufacturing tools, flat products, etc., can solve the problems of easy moisture absorption, poor heat resistance, etc. The effect of surface area and surface energy increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

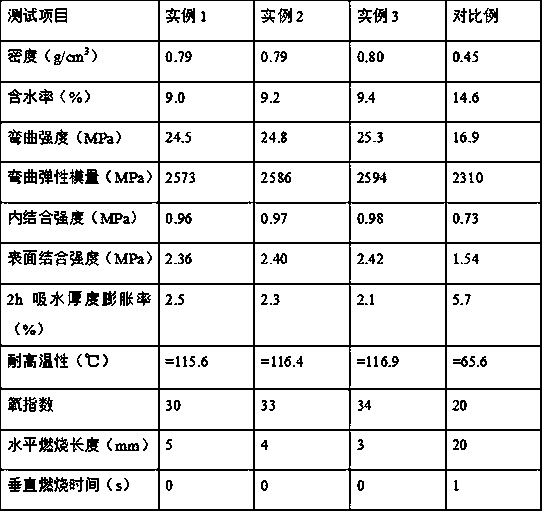

Examples

example 1

[0027]Mix melamine and formaldehyde solution in a beaker with a mass ratio of 1:4, put the beaker in a water bath at a temperature of 80°C and react for 1 hour to obtain a prepolymer, and then put 30% of the mass of the prepolymer into the beaker Ammonium polyphosphate powder, continue to react in a water bath at 80°C for 2 hours, filter the cake after the reaction is over, put the filter cake into a dryer, set the temperature at 105°C, and dry for 40 minutes to obtain modified ammonium polyphosphate; In terms of parts by weight, weigh 10 parts of the above-mentioned modified ammonium polyphosphate, 20 parts of absolute ethanol, and 10 parts of distilled water and put them into a beaker for mixing, stir for 10 minutes, and drop ammonia water with a mass fraction of 25% in the beaker to adjust the pH value to 10.0 to obtain a flame retardant solution, then add vinyltriethoxysilane with 10% mass of the flame retardant solution into the beaker, heat the beaker in a water bath to 5...

example 2

[0029] Mix melamine and formaldehyde solution in a beaker with a mass ratio of 1:4, put the beaker in a water bath at a temperature of 83°C and react for 1 hour to obtain a prepolymer, and then put 35% of the mass of the prepolymer into the beaker Ammonium polyphosphate powder, continue to react in a water bath at 83°C for 3 hours, filter the filter cake after the reaction, put the filter cake in a dryer, set the temperature at 107°C, and dry for 50 minutes to obtain modified ammonium polyphosphate; In terms of parts by weight, weigh 13 parts of the above-mentioned modified ammonium polyphosphate, 23 parts of absolute ethanol, and 13 parts of distilled water and put them into a beaker for mixing, stir for 13 minutes, and drip ammonia water with a mass fraction of 30% in the beaker to adjust the pH value to 10.2, get the flame retardant liquid, then add vinyltriethoxysilane with 13% flame retardant liquid mass into the beaker, heat the beaker in a water bath to 61°C, react at co...

example 3

[0031] Mix melamine and formaldehyde solution in a beaker with a mass ratio of 1:4, put the beaker in a water bath at a temperature of 85°C and react for 2 hours to obtain a prepolymer, and then put 40% of the mass of the prepolymer into the beaker Ammonium polyphosphate powder, continue to react in a water bath at 85°C for 4 hours, filter the filter cake after the reaction, put the filter cake into a dryer, set the temperature at 110°C, and dry for 60 minutes to obtain modified ammonium polyphosphate; In terms of parts by weight, weigh 15 parts of the above-mentioned modified ammonium polyphosphate, 25 parts of absolute ethanol, and 15 parts of distilled water and put them into a beaker for mixing, stir for 15 minutes, and drop ammonia water with a mass fraction of 35% in the beaker to adjust the pH value to 10.4, get the flame retardant liquid, then add vinyltriethoxysilane with 15% flame retardant liquid mass into the beaker, heat the beaker in a water bath to 70°C, react at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com