[0003] At present, the surface of the

battery cell design of the automotive

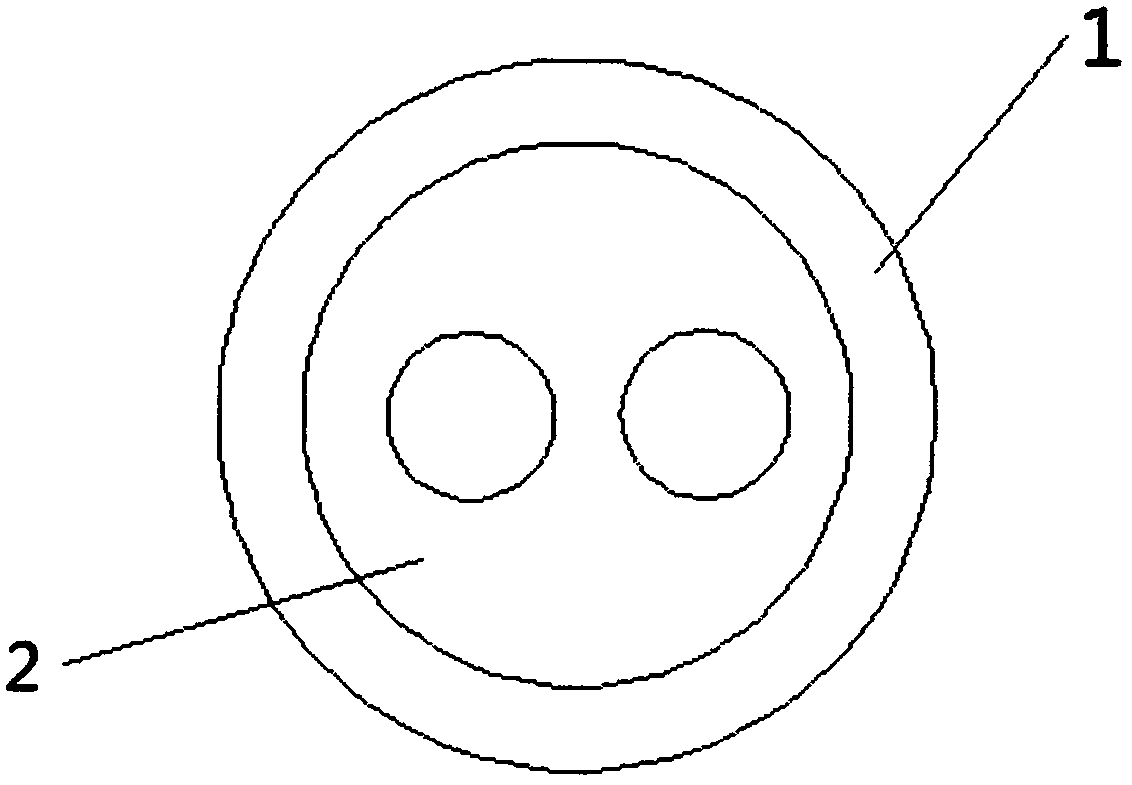

power battery assembly module is made of PVC

heat shrinkable sleeve. Because the PVC is thicker and softer, and the

temperature resistance is lower, as the temperature rises, its surface is easy to crack and it will change under high temperature. Soft, low-temperature hardening, its molecular structure is unstable; in the whole Pack (car

battery pack)

design process, the module (module) design is very important, because the structural

instability of PVC material will lead to the difference between the

cell and the

cell The tolerance range between them is too large, which leads to the

structural stability of the entire module and buryes safety hazards. Considering the bumps in the driving process of the car and the

mechanical vibration caused by the self-vibration of the engine, the

structural stability design of Pack has become particularly important. Important, because due to the existence of

mechanical vibration, if the tolerance between the cells in the module is not controlled in a reasonable range or even if the tolerance is controlled in a reasonable range in the early stage of design, due to the molecular structure of the material during use The

instability of the battery leads to the change of the tolerance of the whole module. The

mechanical vibration during the driving process will cause the frictional collision between the

battery cell and the

battery cell and the frictional collision between the battery cell and the module shell. Over time, the battery cell will cause external

Short circuit, when the temperature of the cell heats up to 65 degrees Celsius, the

electrolyte in it will generate gas, and the

internal pressure will increase. When the

internal pressure increases to a certain value, the cell will leak, and the leakage will aggravate the

insulation failure of the module. Pack products at that time have no insulation safety performance at all, and even the problems caused by 18650

battery pack products will be more serious, such as fire and explosion

[0004] At the same time, the existing automotive

power battery assembly module design uses barley paper and

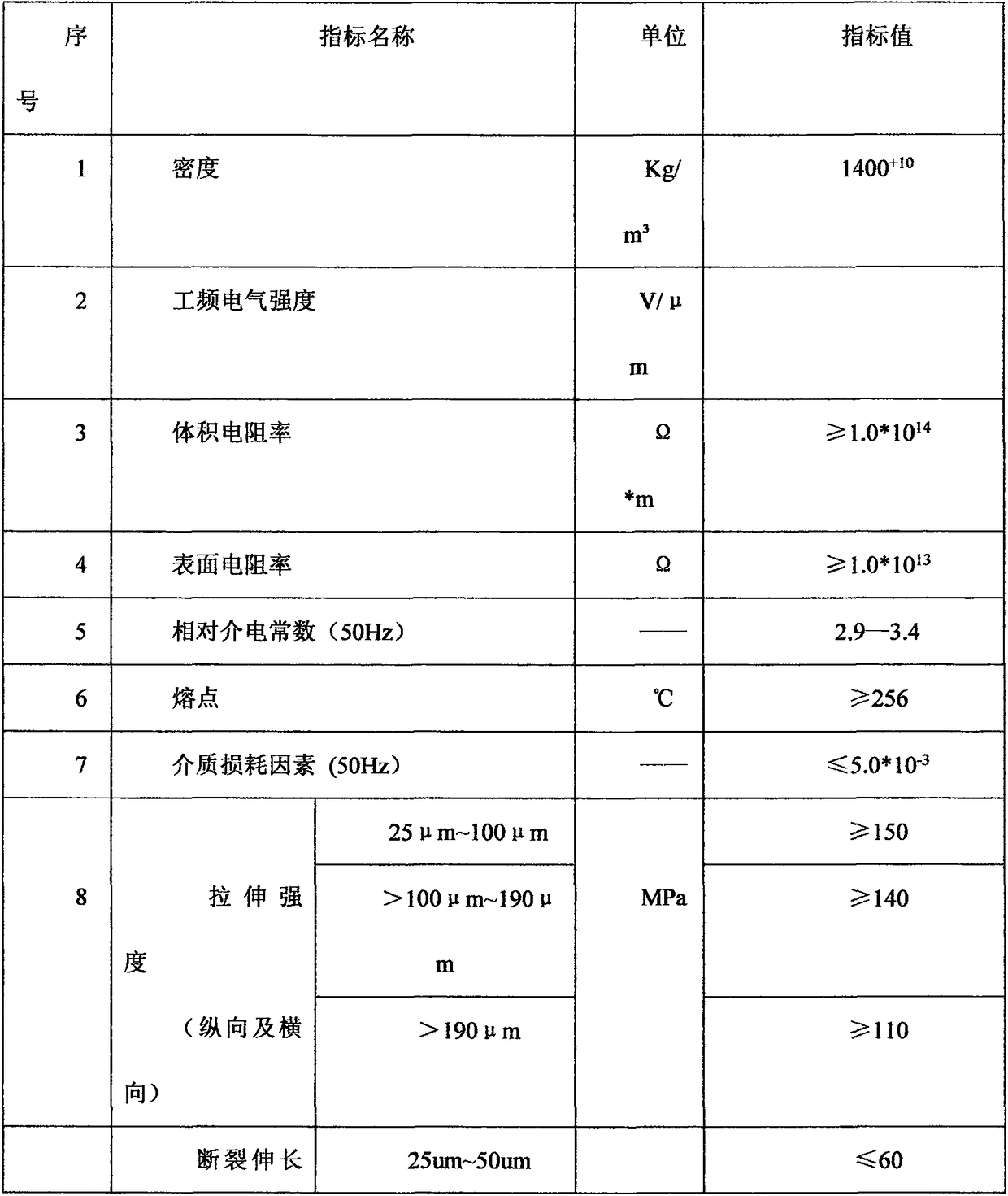

epoxy resin boards between the batteries to achieve the effect of external insulation between the batteries; the barley paper has good

mechanical strength and high Electrical strength, the outer surface is smooth and tough, and the

epoxy resin board has good

mechanical strength, whether it is longitudinal and transverse tensile strength or bending and

compressive strength, the

dielectric constant is 5.5f / m, and the conventional

temperature resistance is 135°C but not Direct contact with the fire source, considering that the medium between the cell and the cell must have high

mechanical strength, high

temperature and pressure resistance, strong insulation performance, and good

thermal conductivity, and it must be self-extinguishing in the presence of flames; At present, most domestic Pack manufacturers use highland barley paper and

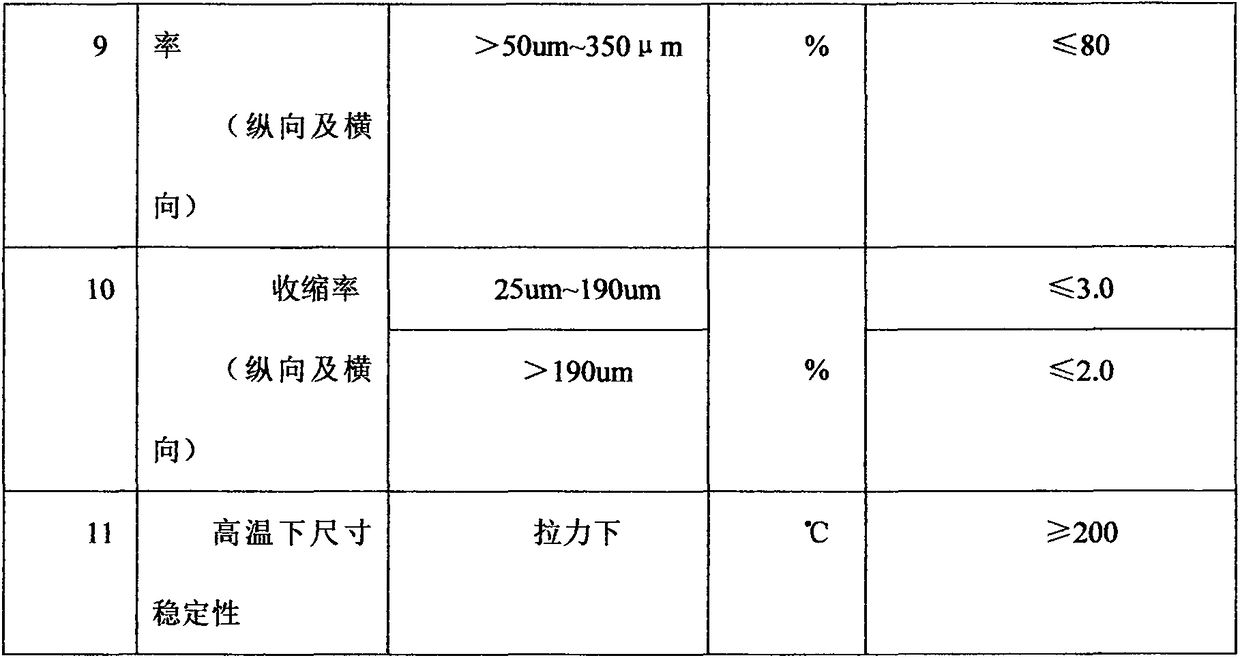

epoxy resin board for the second external insulation between the battery cells when making modules, but because the highland barley paper has good insulation performance but does not have good heat conduction The same is true for epoxy resin boards;

heat energy flows in the form of a medium and exists on the surface of objects or in the air. The way solids conduct heat is from one part of the

system to another or from one

system to another. It is a

solid The main form of

heat transfer; there is another way for solids to transfer heat, that is, heat

radiation; since the temperature that the

battery electrolyte can withstand is lower than 70 ° C, heat

radiation transfer is not considered, mainly the form of heat conduction, that is, the object Direct contact with objects; in the module design, materials with poor

thermal conductivity are used between the battery cells and the battery cells and the sheet

metal parts of the module.

Oxygen resin plate is used as the

dielectric material between the battery core and the battery core. The insulation performance is better than other general materials, but the

thermal conductivity is stretched. The battery generates a lot of heat when charging and discharging or when the car is running. If it cannot be conducted to other objects, it will cause the temperature of the battery body to rise, and then lead to a decrease in the performance of the battery. Since this is a design that cannot be compensated, it should be avoided in the early stage of the design.

At present, the biggest headache for domestic automakers is the problem related to the unbalanced

internal temperature of the Pack. In the early stage of design, if a material with good insulation performance and good heat conduction performance can be used to solve this problem, of course only A

small range is used to solve the problem of temperature balance. The main problem of temperature balance needs to be solved by innovations in structural performance, structure and materials.

Login to View More

Login to View More