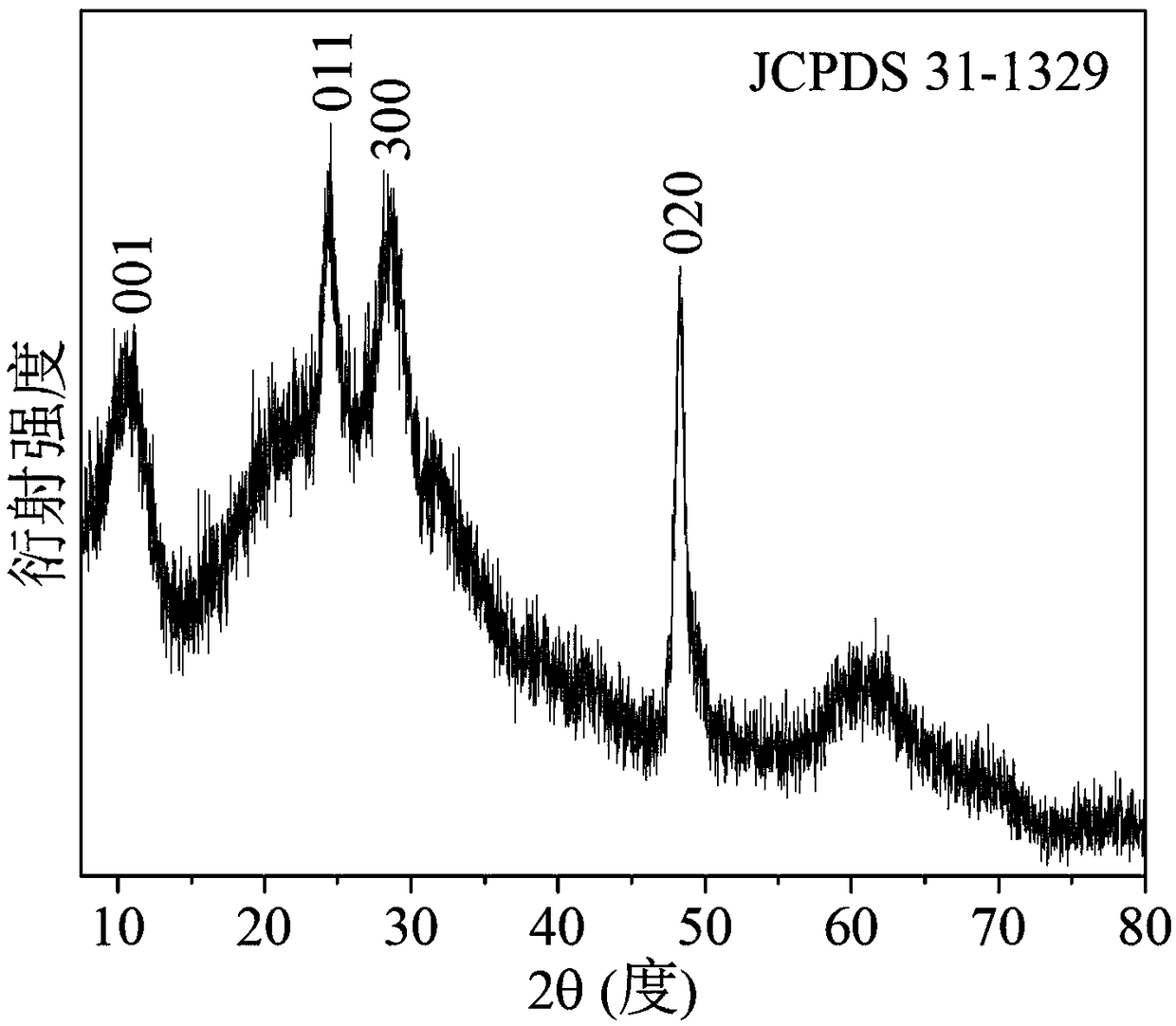

Biomass graded porous carbon-loaded nano-structure sodium titanate, and preparation method thereof

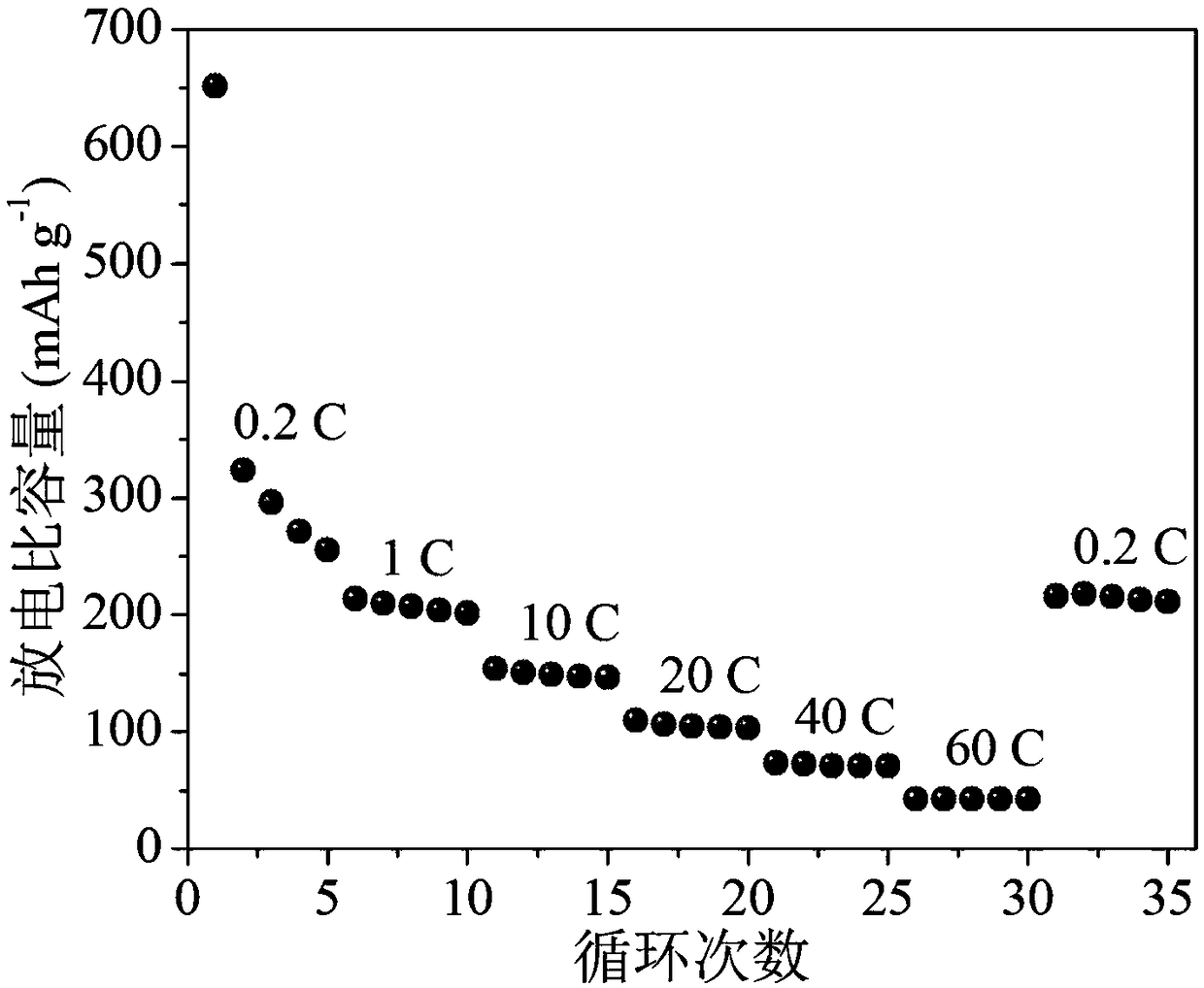

A structural sodium titanate, hierarchically porous technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor cycle stability and poor rate performance, and avoid thermodynamic stability. Low conductivity, improved conductivity, and reduced ion diffusion paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]A preparation method of biomass graded porous carbon-supported nanostructure sodium titanate, comprising the following steps:

[0026] (1) Wash 10 g of cotton stalks with deionized water and ethanol, dry them, cut them into pieces and soak them in 150 mL of 6M KOH aqueous solution for 8 hours, then separate the cotton stalk fragments from the lye by suction filtration, and directly Dry in a blast oven at 80°C for 12h, then calcinate at 800°C for 2h under an argon atmosphere, then wash with 2M aqueous hydrochloric acid and deionized water until the pH of the filtrate is close to 7, and finally in a blast oven at 80°C Dry for 12 hours to obtain biomass graded porous carbon;

[0027] (2) Weigh 0.06g of the biomass graded porous carbon obtained in step (1) and disperse it in 15g of ethanol. After ultrasonically dispersing for 30 minutes, slowly add 0.678g of tetraisopropyl titanate under stirring conditions, and then place it in a 50°C oil bath Ethanol was evaporated to dry...

Embodiment 2

[0039] The preparation method of biomass graded porous carbon-loaded nanostructure sodium titanate comprises the following steps:

[0040] (1) The preparation method of biomass graded porous carbon is the same as the step (1) of embodiment 1;

[0041] (2) Weigh 0.06g of the biomass graded porous carbon obtained in step (1) and disperse it in 3g of isopropanol. After ultrasonically dispersing for 30 minutes, slowly add 0.3g of tetrabutyl titanate under stirring conditions, and then in 100°C oil Evaporate isopropanol to dryness under bath conditions;

[0042] (3) Disperse the powder obtained in step (2) in 60mL of 1M aqueous sodium hydroxide solution, and conduct a hydrothermal reaction at 120°C for 24h;

[0043] (4) Wash the precipitate obtained in step (3) with deionized water and ethanol, dry it in a blast drying oven at 120°C for 6h, and finally heat-treat it at 300°C for 8h under an argon atmosphere to obtain a biomass graded porous carbon / nano Structure Na 2 Ti 3 o 7 ...

Embodiment 3

[0045] The preparation method of biomass graded porous carbon-supported nanostructure sodium titanate comprises the following steps:

[0046] (1) Wash 10 g of cotton stalks with deionized water and ethanol, dry them, cut them into pieces and soak them in 1L of 1M KOH aqueous solution for 8 hours, then separate the cotton stalk fragments from the lye by suction filtration, and directly Dry in a blast oven at 120°C for 6h, then calcinate at 700°C for 8h in an argon atmosphere, then wash with 2M aqueous hydrochloric acid and deionized water until the pH of the filtrate is close to 7, and finally in a blast oven at 120°C Dry for 6h to obtain biomass graded porous carbon;

[0047] (2) Weigh 0.06g of the biomass graded porous carbon obtained in step (1) and disperse it in 15g of chloroform. After ultrasonic dispersion for 30 minutes, slowly add 0.678g of tetraethyl titanate under stirring conditions, and then in 50 ℃ oil bath condition The chloroform was evaporated to dryness;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com