Bismuth vanadate-magnesium ferrite composite photocatalyst, and preparation method and application thereof

A magnesium ferrite, composite light technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of easy recombination, separation and recovery of photogenerated electrons and holes Difficulty, low photocatalytic efficiency and other problems, to achieve the effect of convenient separation and recycling, high catalytic efficiency, and better photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Step 1: Preparation of m-BiVO by sol-gel technique 4 Precursor body fluid: prepare ethylene glycol solution according to the volume ratio of ethylene glycol and deionized water as 1:2, weigh 9.7g of bismuth nitrate pentahydrate and 15.37g of citric acid, dissolve them in 25ml of ethylene glycol aqueous solution, and keep stirring to obtain Solution A: Weigh 2.34g of ammonium metavanadate and dissolve it in 25ml of ethylene glycol aqueous solution and keep stirring to obtain solution B. Add solution B dropwise to solution A at a rate of 30 drops / min under continuous stirring, and adjust the pH value to 9 with ammonia water, heat and stir in a water bath to evaporate part of the solvent to obtain m-BiVO 4 Precursor fluid.

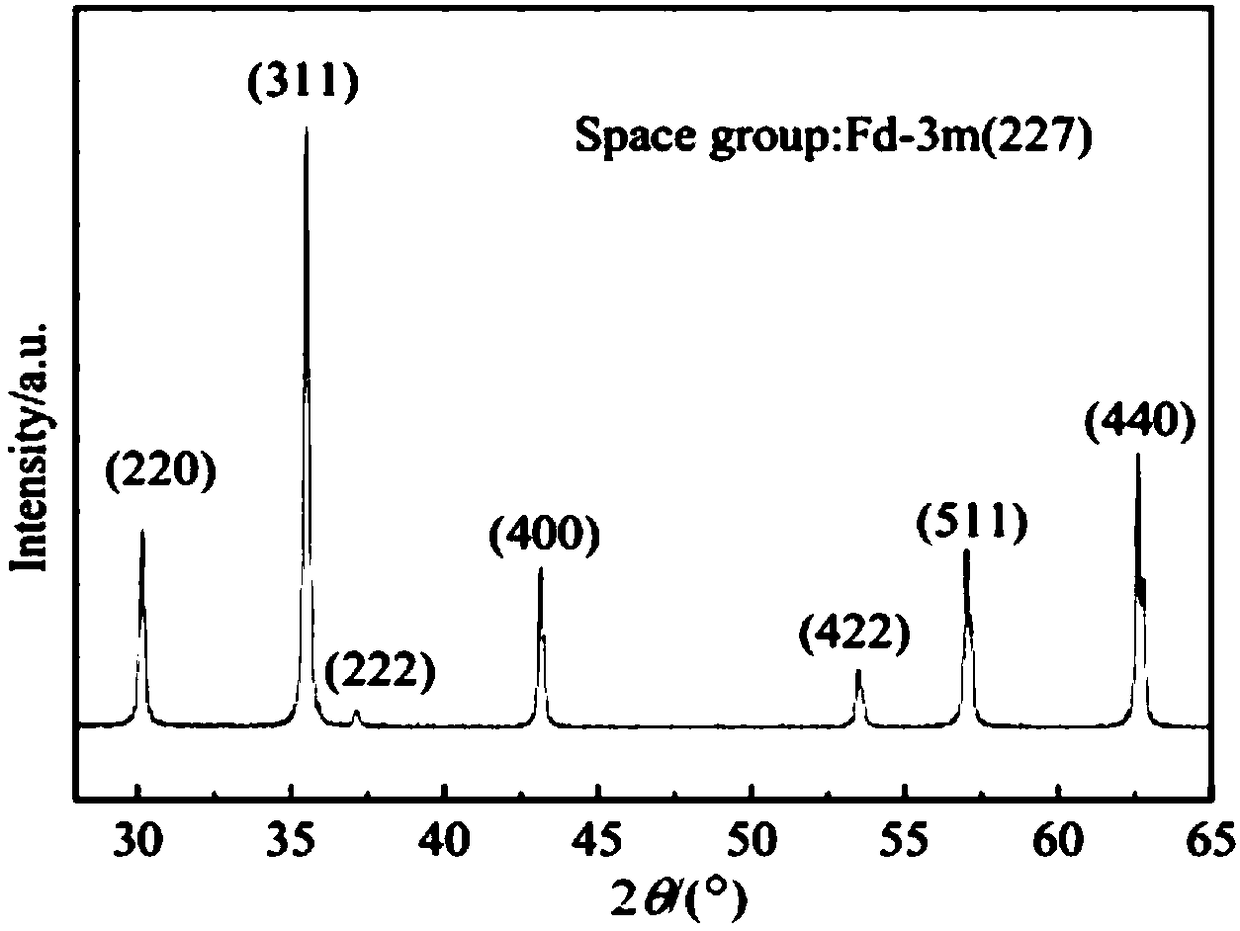

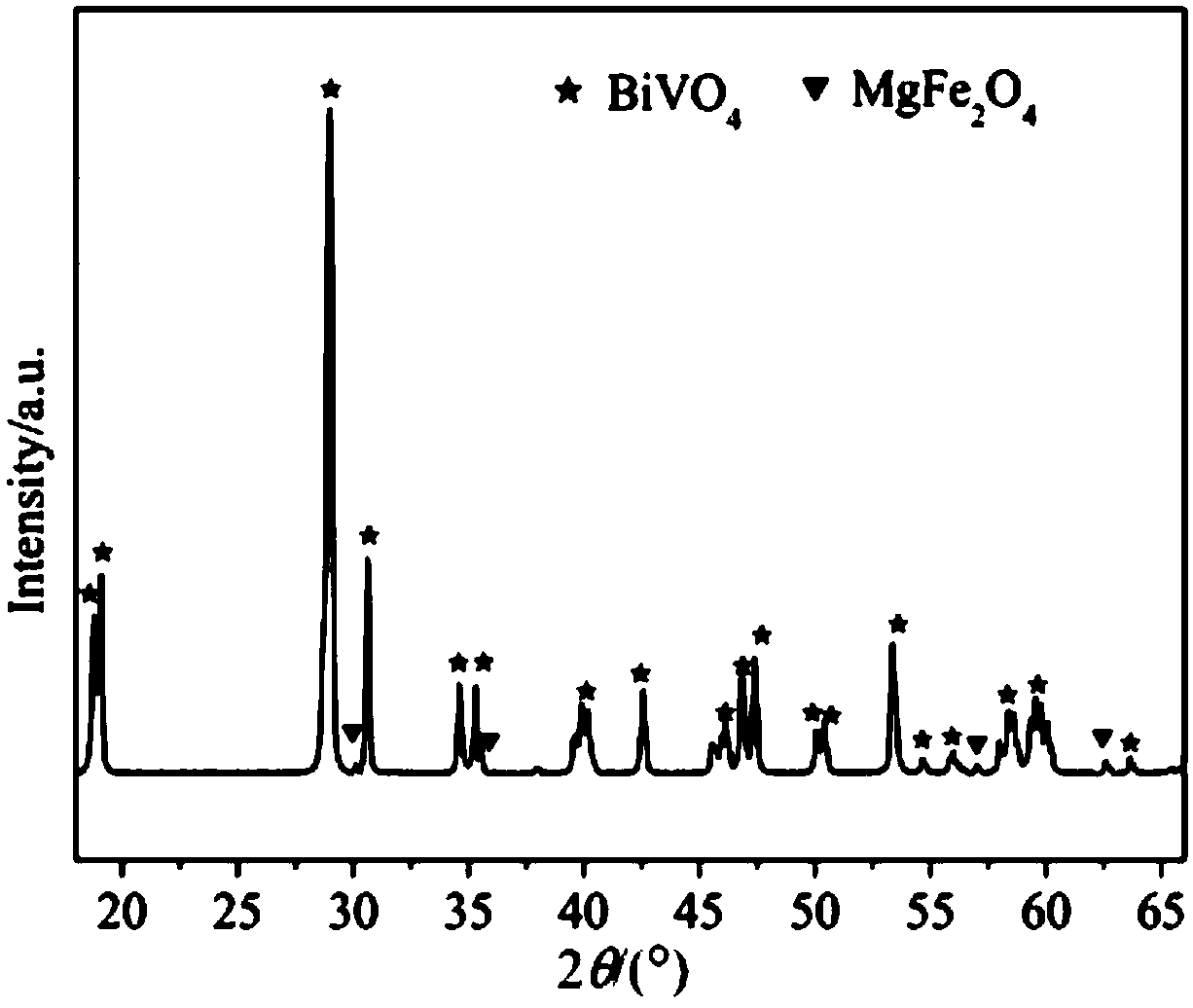

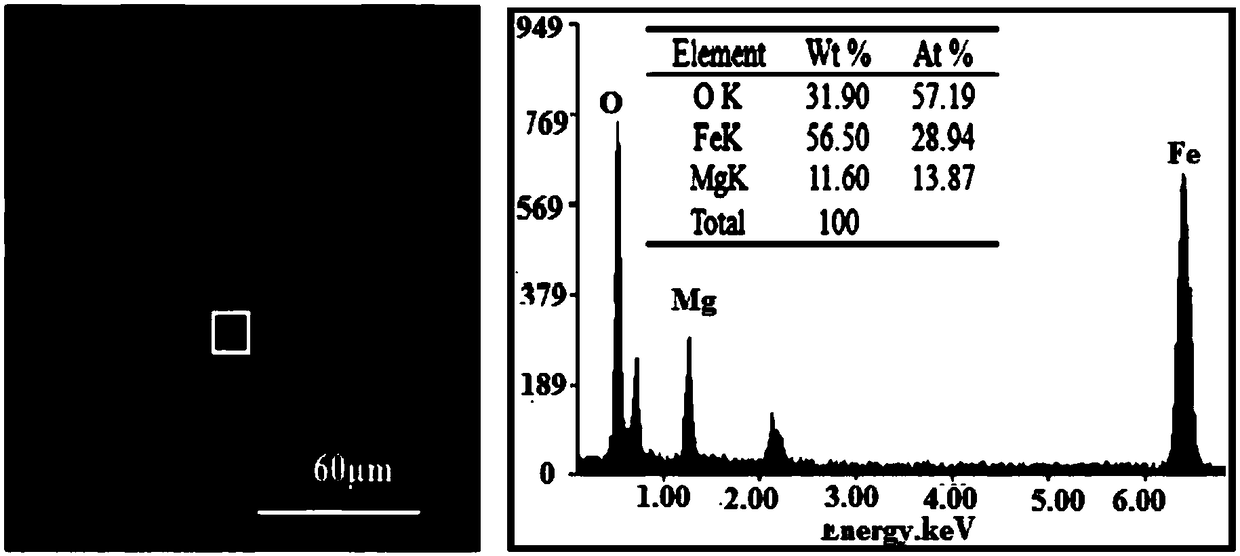

[0053] Step 2: Preparation of MgFe by self-propagating sol-gel combined with high-temperature calcination 2 o 4 Nano powder. Prepare ethylene glycol solution according to the volume ratio of ethylene glycol and deionized water as 1:2, weigh 20.2 g ...

Embodiment 2

[0062] Step 1: Preparation of m-BiVO by sol-gel technique 4 Precursor body fluid: prepare ethylene glycol solution according to the volume ratio of ethylene glycol and deionized water as 1:2.5, weigh 6.7g of bismuth nitrate pentahydrate and 15g of citric acid into 20ml of ethylene glycol aqueous solution, and keep stirring to obtain solution A Dissolve 1.05g of ammonium metavanadate into 20ml of ethylene glycol aqueous solution and keep stirring to obtain solution B. Add solution B dropwise to solution A at a rate of 30 drops / min under continuous stirring, adjust the pH value to 7 with ammonia water, heat and stir in a water bath to evaporate part of the solvent to obtain m-BiVO 4 Precursor fluid.

[0063] Step 2: Preparation of MgFe by self-propagating sol-gel combined with high-temperature calcination 2 o 4 Nano powder. Prepare the ethylene glycol solution according to the volume ratio of ethylene glycol and deionized water as 1:2, weigh 18.05 g of ferric nitrate nonahyd...

Embodiment 3

[0067] Step 1: Preparation of m-BiVO by sol-gel technique 4 Precursor body fluid: prepare ethylene glycol solution according to the volume ratio of ethylene glycol and deionized water as 1:2, weigh 8.54g of bismuth nitrate pentahydrate and 19g of citric acid, dissolve them in 35ml of ethylene glycol aqueous solution, and keep stirring to obtain a solution A: Dissolve 3.52g of ammonium metavanadate in 35ml of ethylene glycol aqueous solution and keep stirring to obtain solution B. Add solution B dropwise to solution A at a rate of 30 drops / min under continuous stirring, and adjust the pH value to 8.5 with ammonia water, heat and stir in a water bath to evaporate part of the solvent to obtain m-BiVO 4 Precursor fluid.

[0068] Step 2: Preparation of MgFe by self-propagating sol-gel combined with high-temperature calcination 2 o 4 Nano powder. The ethylene glycol solution was prepared according to the volume ratio of ethylene glycol and deionized water as 1:2, and 22.52 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com