Environmentally friendly anhydrous taphole clay

An anhydrous taphole clay and an environment-friendly technology, which is applied in the field of anhydrous taphole clay for blast furnaces, can solve the problems of emitting acid, spicy, odor, threatening human health, environmental pollution, etc., and achieves less smoke and is beneficial to construction operations. , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

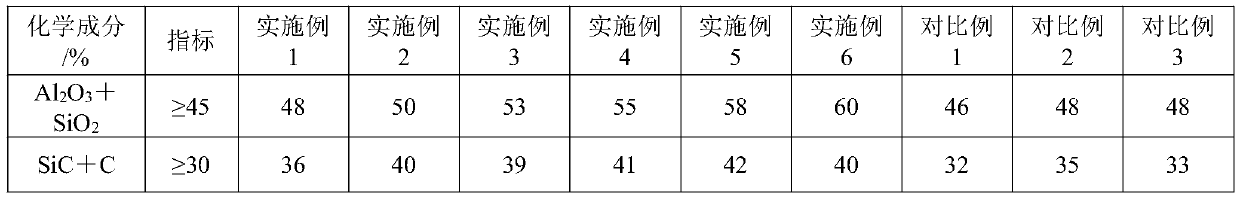

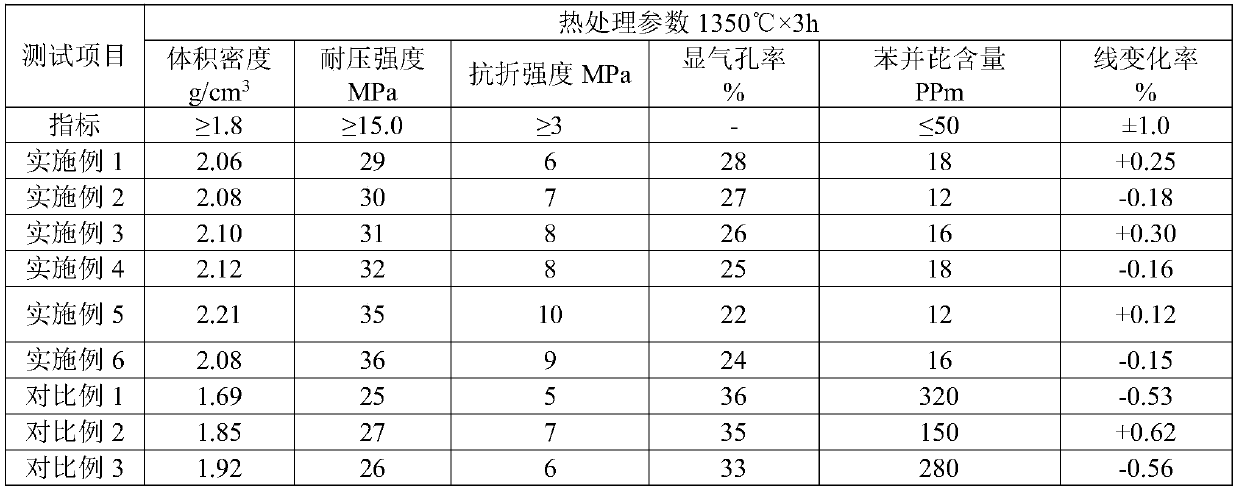

Embodiment 1

[0035] First, 25kg of brown corundum aggregate, 10kg of high alumina fine powder, 8kg of clay, 5kg of kyanite, 5kg of C 60 , 2kg of graphene, 3kg of carbon fiber, 5kg of ferrosilicon nitride, and 10kg of silicon carbide are evenly mixed, then add the binder provided in 15kg of binder preparation example 1, and roll and knead it to obtain an environmentally friendly anhydrous Cannon mud.

Embodiment 2

[0037] First, 30kg of brown corundum aggregate, 15kg of high alumina fine powder, 10kg of clay, 6kg of kyanite, 6kg of C 60, 4kg of graphene, 4kg of carbon fiber, 10kg of ferrosilicon nitride, and 15kg of silicon carbide are mixed evenly, then add the binder provided in 12kg of binder preparation example 2, and roll and knead it to obtain an environmentally friendly anhydrous Cannon mud.

Embodiment 3

[0039] First, 35kg of brown corundum aggregate, 20kg of high alumina fine powder, 15kg of clay, 8kg of kyanite, 9kg of C 60 , 6kg of graphene, 5kg of carbon fiber, 15kg of ferrosilicon nitride, and 20kg of silicon carbide are evenly mixed, then add the binder provided in 10kg of binder preparation example 3, and roll and knead it to obtain an environmentally friendly anhydrous Cannon mud.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com