Preparation method of water-based super-hydrophobic material

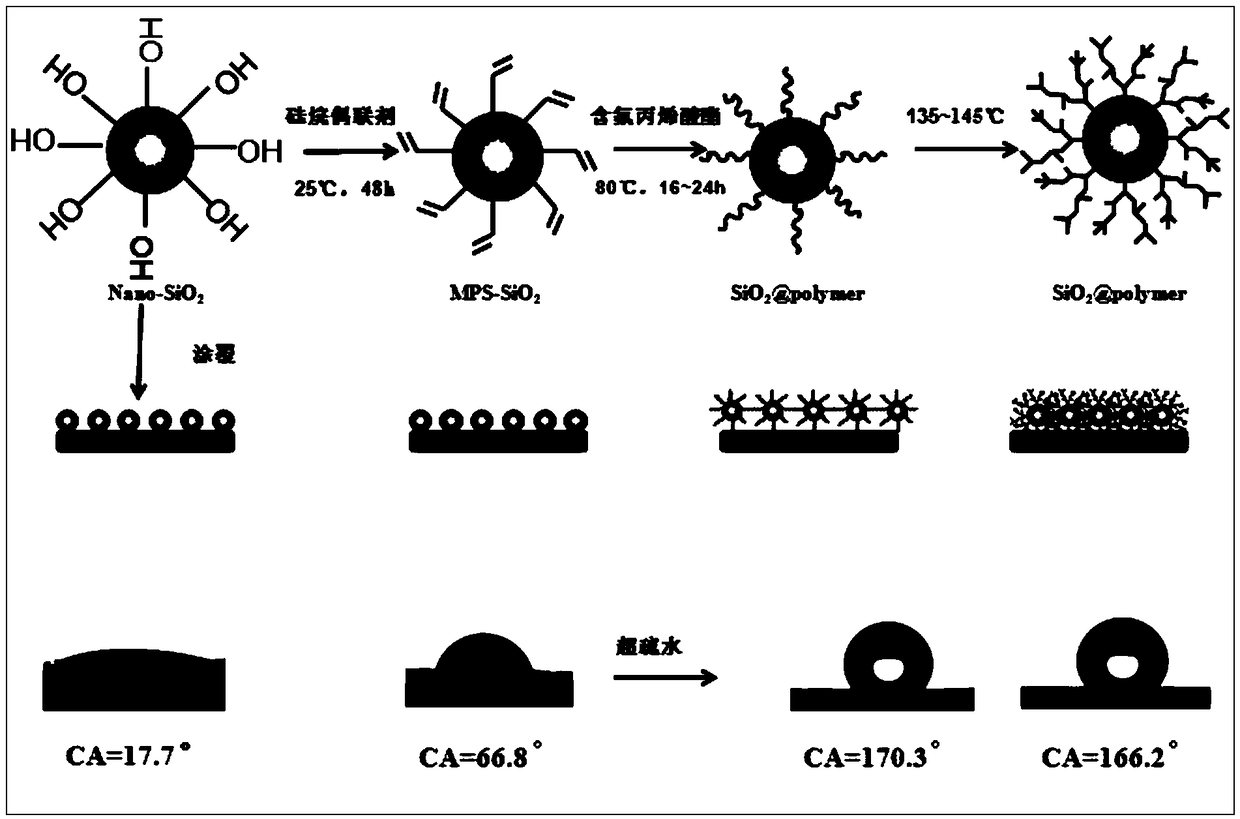

A super-hydrophobic and water-based technology, applied in the field of preparation of water-based super-hydrophobic materials, can solve the problems such as difficulty in properly blending adhesives and nanoparticles, poor durability, environmental pollution, etc., achieving good industrial development and application prospects, increasing wear resistance performance, easy to prepare and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of material with 52.3% grafting

[0037] (1) Modification of silica (particle size 10-100nm)

[0038] Take 2g of silicon dioxide and disperse it in 200ml of ethanol, ultrasonically disperse for 30min, then add 10ml of double distilled water, 2ml of ammonia water (mass fraction 25-28%) and 6g of γ-methacryloxypropyltrimethoxy Silane, the stirring speed is controlled at 300r / min, the reaction is stopped after 48 hours at room temperature, the product is washed with ethanol several times, and after vacuum drying, the surface-modified silica is obtained.

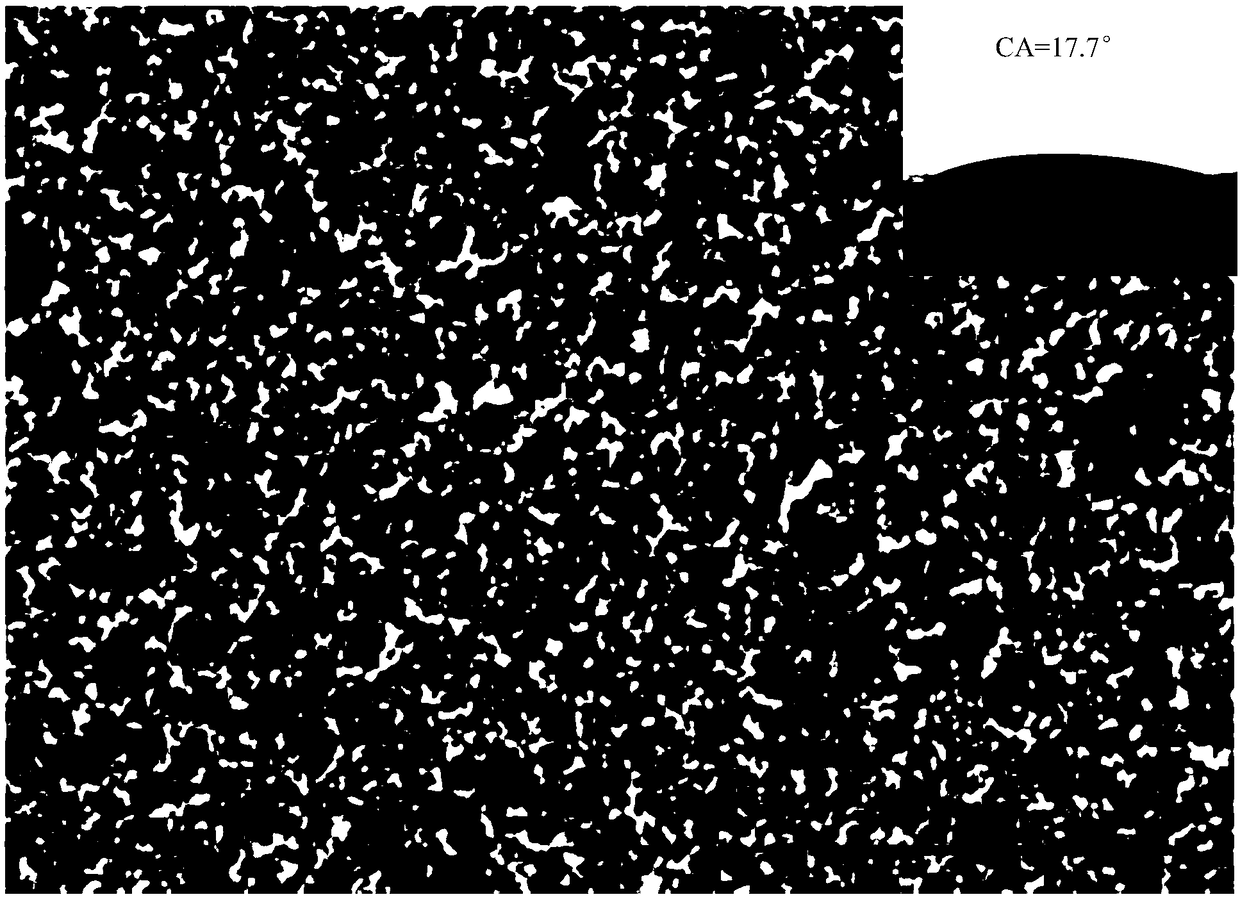

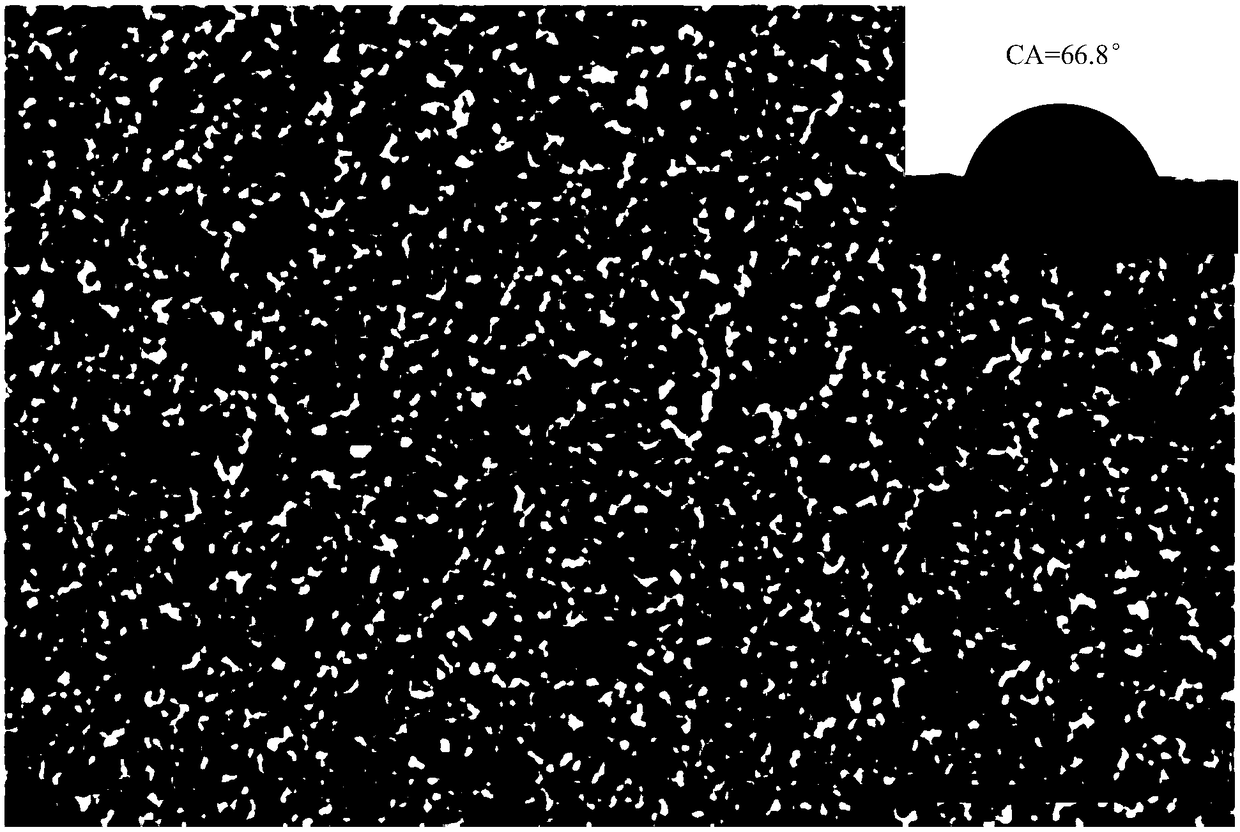

[0039] attached figure 2 It was obtained by scanning silicon dioxide with a FEI Nano SEM 450 electron scanning electron microscope, image 3 It is the electron micrograph of modified silicon dioxide. From attached figure 2 with 3 It can be seen that there is no significant change in the morphology of the silica before and after modification, and there is a hydrophobic silane coupling agent on the modifi...

Embodiment 2

[0044] Preparation of material with 60.4% grafting

[0045] (1) Silica modification is the same as the first step of the implementation case (1)

[0046] (2) Emulsion polymerization for surface grafting reaction of modified silica

[0047] Disperse dry 1g of modified silicon dioxide in 100ml of double distilled water, ultrasonically disperse for 30min, then add 0.24g of sodium bicarbonate (NaHCO 3 ), 0.13g sodium dodecylsulfonate (SDS), ultrasonically dispersed for 30min, added to the reactor, heated to 80°C in an oil bath, fed with argon, mechanically stirred at a stirring speed of 250r / min, and then returned to the reaction system Add 4g of dodecafluoroheptyl methacrylate to the solution, and make the emulsion for 30min. Dissolve 0.08g of potassium persulfate in 10ml of water. After the dissolution is complete, add it dropwise to the reaction system. After 1h, the reaction is carried out at a constant temperature of 80°C for 18h, and the obtained emulsion Stand still to ob...

Embodiment 3

[0049] Preparation of material with 65.9% grafting

[0050] (1) Silica modification is the same as the first step of the implementation case (1)

[0051] (2) Emulsion polymerization for surface grafting reaction of modified silica

[0052] Disperse the dried 1g of modified silica in 100ml of double distilled water, add 0.24g of sodium bicarbonate (NaHCO 3 ), 0.20g of sodium dodecylbenzenesulfonate (SDS), ultrasonically dispersed for 30min, added to the reactor, heated to 80°C in an oil bath, fed with argon, stirred mechanically, and then added 6g of methyl Dodecafluoroheptyl acrylate, emulsion 30min, dissolve 0.12g potassium persulfate in 10mL water, drop it into the previous reactor after dissolving completely, drop it in 1h, stir at 250r / min, react at a constant temperature of 80°C for 20h, put Gained emulsion is left standstill, and the water-based superhydrophobic material that obtains grafting amount is 65.9%; This material is added in water, is mixed with the dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com